ASA/AS and modified PC co-extrusion material, preparation method and application thereof

A modified and outer layer material technology, applied in the field of ASA and PC composite materials, can solve the problems of poor wear resistance, poor solvent resistance and alkali resistance of polycarbonate, and achieve the effect of improving dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

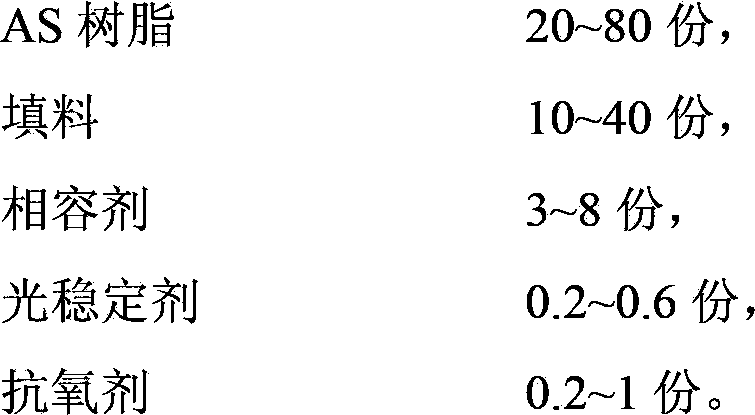

[0039] Weigh the outer material ASA / AS raw materials: 50 parts of ASA resin (the content of acrylate in the rubber phase is 30%), 50 parts of AS resin (the content of acrylonitrile is 20%, the melt index is 5g / 10min), 20 parts of glass fiber , 0.4 parts of 2-hydroxy-4-n-octyloxybenzophenone, 0.2 parts of tris(2,4-di-tert-butylphenyl) phosphite, 3 parts of ASA-g-MAH;

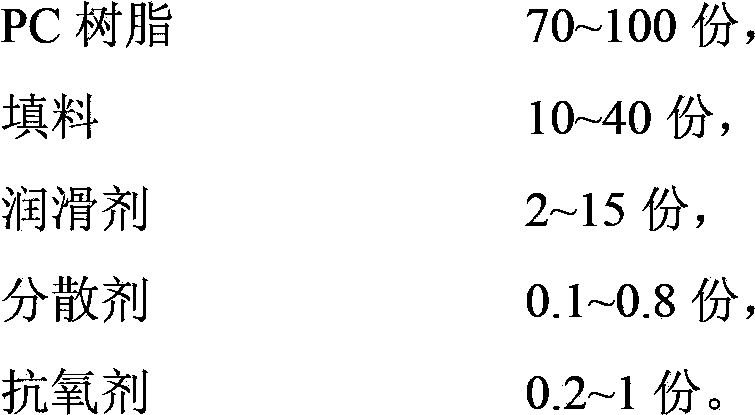

[0040] Weigh the modified PC raw material of the inner layer material: 70 parts of PC resin (its melt index is 5g / 10min), 10 parts of glass fiber, 2 parts of lauric acid diethanolamide, 0.2 parts of β-(4-hydroxy-3,5- Di-tert-butylphenyl) n-octadecyl propionate, 0.8 part of glyceryl tristearate;

[0041] First mix the outer layer raw materials and the inner layer raw materials separately, put them in two mixers for mixing, first knead at a high speed, the speed is 400r / min, the temperature reaches 90°C, then cool and mix to about 40°C and feed; mix After uniformity; the modified PC material of the inner layer is ...

Embodiment 2

[0046] Weigh the outer material ASA / AS raw materials: 20 parts of ASA resin (the content of acrylate in the rubber phase is 70%), 80 parts of AS resin (the content of acrylonitrile is 50%, the melt index is 10g / 10min), 40 parts of solid glass Microbeads, 0.6 parts of N,N'-bis(2,2,2,6-tetramethyl-4-piperidinyl)-1,6-hexanediamine, 1 part of tetrakis[β-(3,5- Di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, 8 parts of polystyrene maleic anhydride grafts;

[0047] Weigh the modified PC raw material of the inner layer material: 100 parts of PC resin (its melt index is 10g / 10min), 30 parts of solid glass microspheres, 15 parts of calcium stearate, 0.5 parts of tetra[β-(3,5-di tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 0.1 part of monoglyceride stearate;

[0048]First mix the outer layer raw materials and the inner layer raw materials separately, put them in two mixers for mixing, first knead at a high speed, the speed is 500r / min, the tempera...

Embodiment 3

[0053] Weigh the ASA / AS raw material of the outer layer material: 80 parts of ASA resin (the content of acrylate in the rubber phase is 50%), 20 parts of AS resin (the content of acrylonitrile is 30%, the melt index is 40g / 10min), 10 parts of mica, 0.2 parts bis-2,2,6,6-tetramethylpiperidinol sebacate, 0.5 parts n-octadecyl alcohol β-(4-hydroxy-3,5-di-tert-butylphenyl)propionate Esters, 5 parts of polystyrene maleic anhydride grafts;

[0054] Weigh the modified PC raw material of the inner layer material: 90 parts of PC resin (its melt index is 7g / 10min), 40 parts of mica, 8 parts of polyethylene wax, 1 part of tris(2,4-di-tert-butylphenyl) Phosphate ester, 0.4 parts of vinyl bis stearamide;

[0055] First mix the outer layer raw materials and the inner layer raw materials separately, put them in two mixers for mixing, first knead at a high speed, the speed is 600r / min, the temperature reaches 100°C, then cool and mix to about 40°C and feed; mix After uniformity; the inner l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com