Middle shaft machining technology

A processing technology and intermediate shaft technology, applied in the field of transmission parts processing, can solve the problem of long processing time of the intermediate shaft, and achieve the effect of improving efficiency, speeding up progress and reducing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A kind of intermediate shaft processing technique in the present embodiment, comprises the following steps:

[0024] a. Cutting material: 20CrMnTiH-GB / T5216-200 material is used.

[0025] b. Forging the billet: the forging billet is processed by die forging.

[0026] c. Isothermal normalizing: the hardness of isothermal normalizing is 160~190HB.

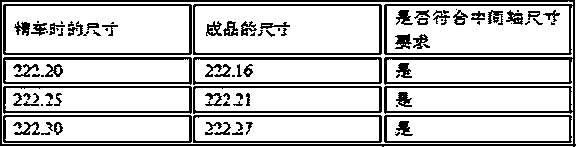

[0027] d. Finishing: for the size of the outer circle, a grinding allowance of 0.25mm is left for the part to be ground, and the rest is processed to the finished product size; the total axial length is 222.2-222.3 mm (the finished product size is 222.2±0.1mm), and the rest of the size is processed to Finished product size; runout of grinding parts and straightening is 0.02mm.

[0028] e. Gear hobbing: CNC five-axis hobbing gear shaving machine is adopted, the center hole at both ends of the shaft is positioned, the expansion sleeve pull rod is connected with the hydraulic cylinder of the machine tool, and the piston of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com