Method for constructing tissue engineering cartilage

A tissue engineering and construction method technology, applied in bone implants, medical science, prostheses, etc., can solve the problems of incomplete decellularization, complicated preparation process, and difficulty in re-growing cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Materials and methods

[0043] 1. Preparation of Gelatin / PCL nanofiber electrospun membrane

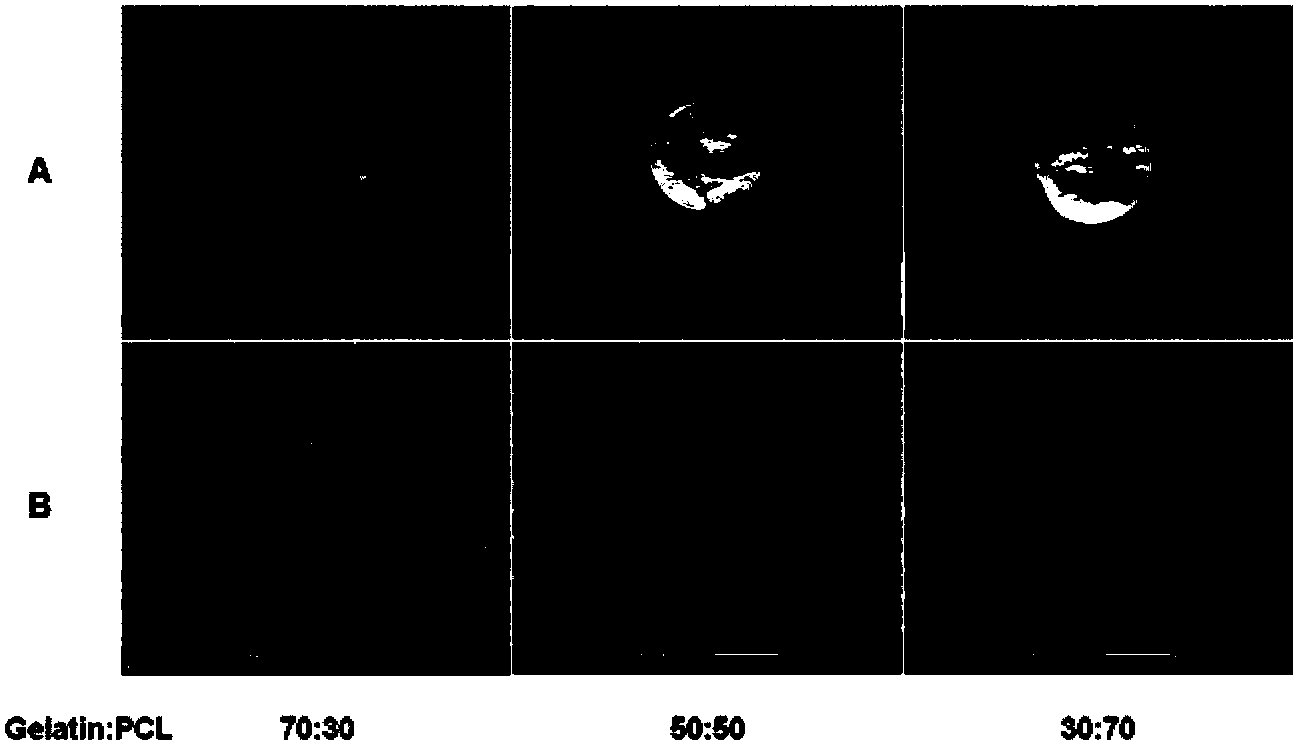

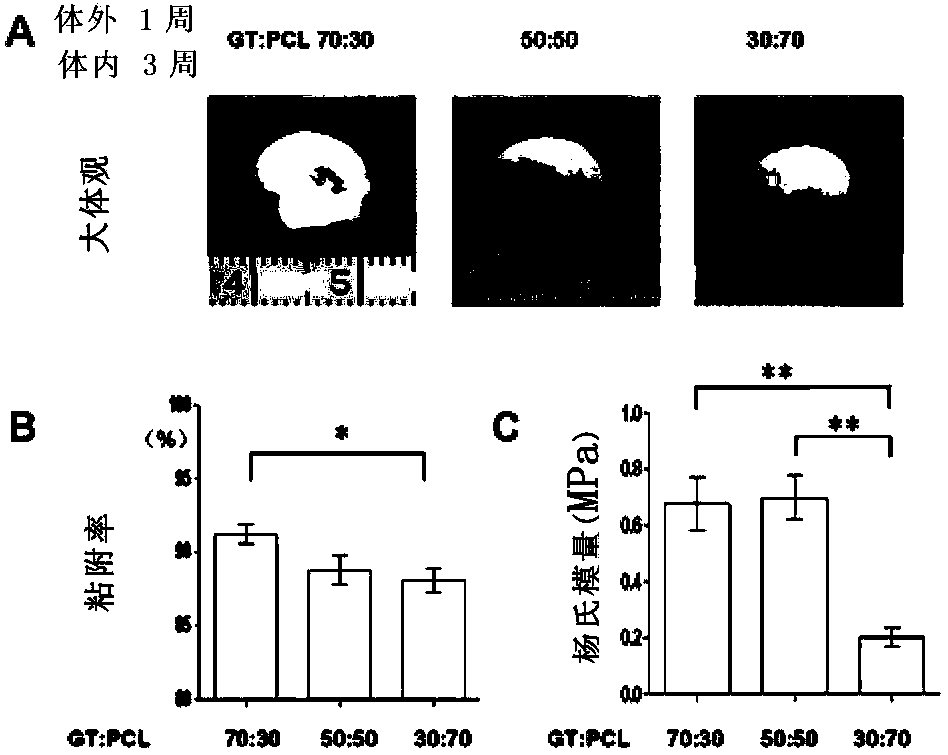

[0044] Gelatin:PCL ratios of Gelatin / PCL nanofiber electrospun membrane materials used in this example include 30:70, 50:50, and 70:30, which were purchased from the Institute of Biology, Donghua University. The material was processed into a circular diaphragm with a diameter of 9 mm by corneal trephine, and it was processed in a vacuum freeze dryer for 24 hours before use (aseptic).

[0045] 2. Culture of auricle chondrocytes

[0046] The auricular cartilage tissue of newborn pigs was taken, cut into 1×1×1 mm size, digested overnight with 0.1% collagenase, filtered through a filter with a pore size of 75 μm, added high-sugar DMEM (Hyclone, USA) containing 10% fetal bovine serum ( FBS) (Hyclone, USA) culture medium, placed in 5% CO 2 Cultured in a 37°C incubator, cultivated to 80%-90% confluence and then passaged.

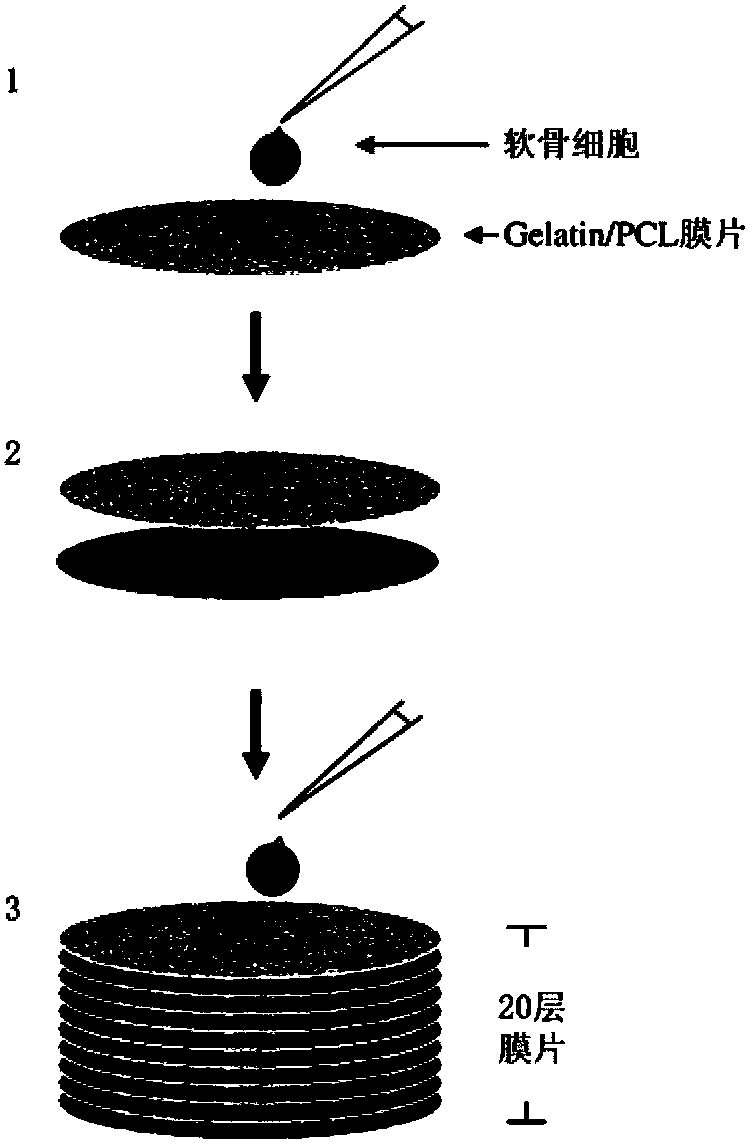

[0047] 3. Sandwich method to build cartilage

[0048] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com