Bean curd as well as preparation method and processing equipment of bean curd

A technology for tofu and soybeans, applied in the field of food processing, can solve the problems of high cost, poor control of hygiene problems, low efficiency, etc., and achieve the effects of high production efficiency, rich taste and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

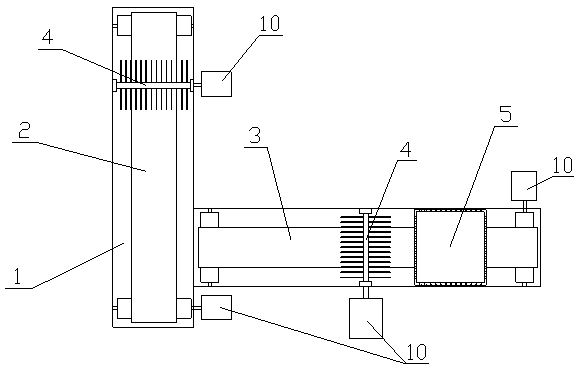

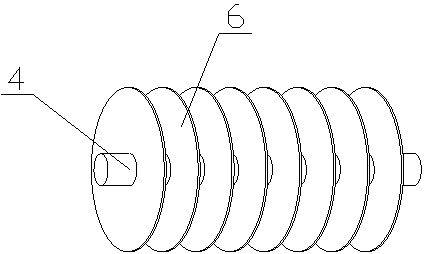

Image

Examples

Embodiment 1

[0034] (1) Put 3 parts of ice water and 15 parts of soybean protein isolate powder into the chopper, chop the protein isolate powder to a fine slurry and no protein particles, add 0.5 part of transglutaminase, and continue to chop until it is evenly dispersed. Add 4 parts of ice water during the chopping process, and control the slurry temperature at 0~12℃;

[0035] (2) Add 3 parts of sugar, 4 parts of salt and 3 parts of MSG, chop and mix evenly;

[0036] (3) Slowly add 8 parts of vegetable oil, turn the chopper to high speed, and chop until fully emulsified;

[0037] (4) Continue to add 10 parts of starch and 8 parts of ice water, control the slurry temperature at 0~12℃, chop and mix evenly to obtain slurry;

[0038] (5) Put the slurry prepared in step (4) into the forming machine, and evenly pour the slurry into the tofu steaming tray through the tofu mold, and place the steaming tray on the steaming car;

[0039] (6) Push the steaming car to a fresh-keeping warehouse with a tempera...

Embodiment 2

[0044] (1) Put 8 parts of ice water and 20 parts of soybean protein isolate powder into the chopper, chop the protein isolate powder to a fine slurry and no protein particles, add 0.8 part of transglutaminase, and continue to chop until it is evenly dispersed. Add 7 parts of ice water during the chopping process, and control the slurry temperature at 0~12℃;

[0045] (2) Add 5 parts of sugar, 3 parts of salt, 4 parts of MSG, chop and mix evenly;

[0046] (3) Slowly add 5 parts of vegetable oil, turn the chopper to high speed, and chop until fully emulsified;

[0047] (4) Continue to add 5 parts of starch and 8 parts of ice water, control the slurry temperature at 0~12℃, chop and mix evenly to obtain the slurry;

[0048] (5) Put the slurry prepared in step (4) into the forming machine, and evenly pour the slurry into the tofu steaming tray through the tofu mold, and place the steaming tray on the steaming car;

[0049] (6) Push the steaming car to a fresh-keeping warehouse with a tempera...

Embodiment 3

[0054] A kind of tofu, the composition of the tofu in parts by weight is: 15-25 parts of soybean protein isolate powder, 5-15 parts of vegetable oil, 5-15 parts of starch, 3~5 parts of white sugar, 3~5 parts of salt, MSG 3 to 5 parts, 0.5 to 1 part of transglutaminase, 15 to 30 parts of ice water; the ice water is prepared by freezing drinking water to 0-5°C.

[0055] A method for preparing tofu as described above includes the following steps:

[0056] (1) Put 13 parts of ice water and 25 parts of soybean protein isolate powder into the chopper, chop the protein isolate powder to a fine slurry and no protein particles, add 1 part of transglutaminase, and continue to chop until it is evenly dispersed. Add 9 parts of ice water during the chopping process to control the slurry temperature at 0~12℃;

[0057] (2) Add 4 parts of sugar, 5 parts of salt and 5 parts of MSG, chop and mix evenly;

[0058] (3) Slowly add 15 parts of vegetable oil, turn the chopper to high speed, and chop until f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com