Application of artemisia extractive as fruit coloring accelerant

An extract and accelerator technology, which is applied in the application field of Artemisia annua extract as a fruit coloring accelerator, can solve the problems of limited application and high price, and achieve the effects of easy acquisition, low cost, and promotion of synthesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

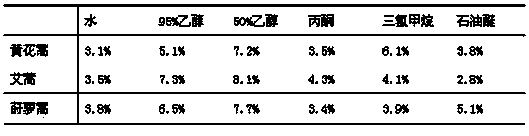

[0029]Example 1 Different organic solvents to the extraction rate of Artemisia plants

[0030] Take 100.0 g of the above three Artemisia sample powders prepared above, and use 1000 ml of 90% ethanol, 50% ethanol, acetone, chloroform, petroleum ether and deionized water to shake and extract 3 times under a water bath shaker at 40 °C, each time with the amount of solvent 500ml, 300ml, and 200ml respectively, and the extraction time was 3, 2, and 1 day respectively. The combined filtrates were concentrated by a rotary evaporator to obtain extracts, weighed, and the extraction rate was measured. The results are shown in Table 1.

[0031] Table 1 Extraction effect of different solvents on Artemisia plants

[0032]

[0033] From the results, the extraction effect of ethanol is obviously better than that of other organic solvents, especially the effect of 50% ethanol is better.

Embodiment 2

[0034] Embodiment 2 The influence of different extraction methods on the extraction rate

[0035] The effects of soaking extraction, continuous extraction and ultrasonic extraction on the extraction rate were studied. The data of soaking extraction method adopts the data of embodiment 1.

[0036] The test method of the continuous extraction method is as follows: Weigh 15.0g of the three kinds of Artemisia spp., wrap them with filter paper, put them into a Soxhlet extractor, inject 150ml of 95% ethanol solution and acetone solution, heat the water bath to 80°C, and continuously After extracting for 6 hours, the extract was concentrated in a rotary evaporator to obtain an extract, which was weighed to measure the extraction rate.

[0037] Ultrasonic extraction test method: Weigh 15.0g of the three kinds of Artemisia spp., pour them into a triangular flask, inject 150ml of 95% ethanol solution and acetone solution, seal, soak for 24 hours, and put them into an ultrasonic cleanin...

Embodiment 3

[0041] Example 3 Effects of Different Method Extracts on Apple Coloring

[0042] Get 1000 grams of dry powder prepared by mugwort, the solvent is 50% ethanol, and the ratio of solid to liquid is 1:10. Extract according to the methods of soaking method, continuous extraction method, and ultrasonic extraction method in Examples 1 and 2. If it cannot be completed once, it can be separated. Multiple times, and finally combine the extracts, concentrate under reduced pressure to 1000ml, and become the original drug containing crude drug 1g / ml.

[0043] For the test Fuji apple is a 10-year-old fruit tree in the full fruit period, a single-branch plot, and repeated 3 times. After removing the bag, 30 days and 15 days before the fruit was harvested, the original medicine obtained by the three methods was diluted 200 times and 100 times respectively. Double and 50 times to spray the fruit trees, focusing on spraying the fruit until all the fruit is sprayed. Add 0.1% Tween-80 to the med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com