Pressure-resistant clamps for carbon fiber conductors

A carbon fiber wire, voltage-resistant wire technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of affecting the transmission capacity of the power grid, easy to produce sag, loose wire strands, etc., to improve connection reliability, avoid self-wear, improve The effect of clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

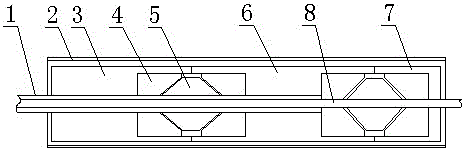

[0015] Such as figure 1 Shown: a pressure-resistant clamp dedicated to carbon fiber wires, including an outer sleeve 2 and an inner member, the inner member includes a compression tube 3 with a groove at one end, a compression tube 6 with grooves at both ends, and a The end pipe 7 of the groove, the compression pipe 6 with grooves at both ends is threadedly connected with the compression pipe 3 and the end pipe 7 with grooves at one end respectively, and the grooves are provided with frustum cavity The structural member 4, the shuttle-shaped collet 5 is arranged in the cavity of the frustum body.

[0016] As a preferred solution of the present invention, both the structural member 4 and the shuttle-shaped collet 5 are made of hard aluminum-magnesium alloy.

[0017] As a further preferred solution of the present invention, the front end of the compression tube 3 with a groove at one end is a compressible deformation zone.

[0018] As a further preferred solution of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com