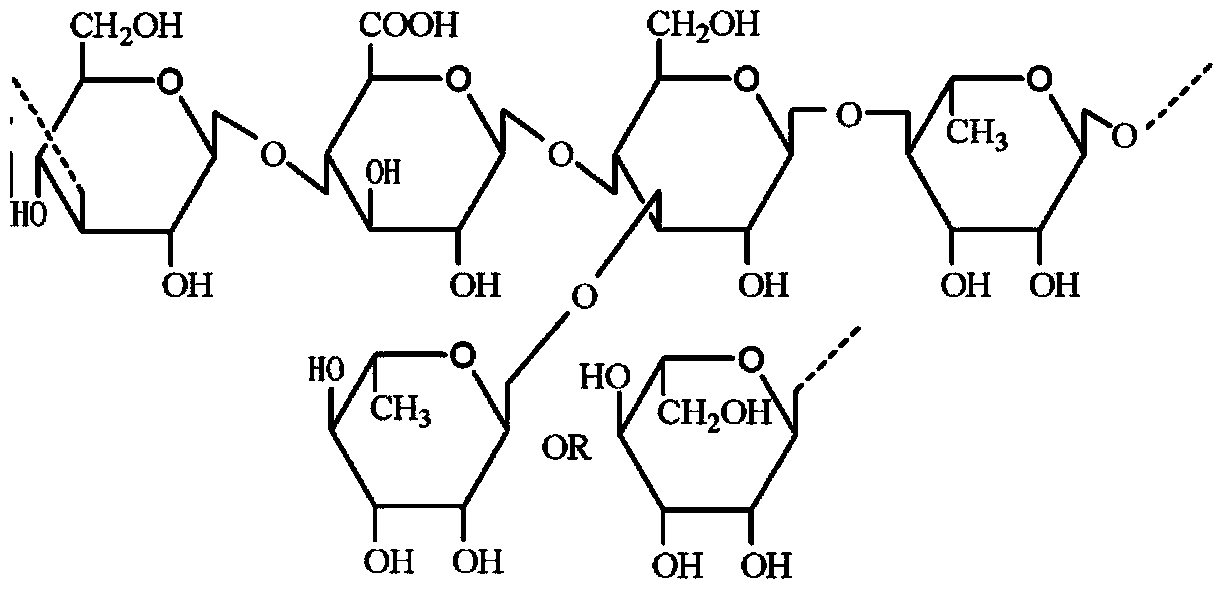

Fermentation method of welan gum

A fermentation method and the technology of welan gum, applied in the field of welan gum fermentation, can solve the problems of no commercial production, etc., and achieve the effects of being beneficial to anabolism, stable properties and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Step 1, preparing hydrolyzed sugar liquid: pretreating cornstarch and enzymatically hydrolyzing it to obtain hydrolyzed sugar liquid with a glucose mass concentration of 3%;

[0047] Step 2, preparation of fermentation medium: take 6L of the hydrolyzed sugar solution obtained in step 1 as a carbon source, and add 0.35% (mass) peptone, 0.2% (mass) K 2 HPO 4, 0.015% (mass) MgSO 4 , 0.2‰ (quality) bubble enemy, make fermentation medium, initial pH7.2;

[0048] Step 3, prepare seed solution: inoculate the activated welan gum production strain ATCC31555 into the seed medium, and cultivate at 28°C for 16 hours to obtain the seed solution; wherein the seed medium (mass concentration %): glucose 1%, peptone 1% , yeast powder 0.50%, K 2 HPO 4 0.2%, MgSO 4 0.01%, initial pH6.5;

[0049] Step 4, Welan Gum Fermentation: Inoculate the seed solution obtained in Step 3 into a 10L fermenter equipped with 6L of the fermentation medium obtained in Step 2 to ferment to obtain a ferm...

Embodiment 2

[0052] Step 1, preparing hydrolyzed sugar liquid: pretreating cornstarch and enzymatically hydrolyzing it to obtain hydrolyzed sugar liquid with a glucose content of 3%;

[0053] Step 2, preparation of fermentation medium: take 6L of the hydrolyzed sugar solution obtained in step 1 as a carbon source, and add 0.35% (mass) peptone, 0.2% (mass) K 2 HPO 4 , 0.15‰ (mass) MgSO 4 , 1‰ (quality) Tween-80, 0.2‰ (quality) soaked in enemy to make fermentation medium, initial pH7.2;

[0054] Step 3, preparation of seed solution: inoculate the activated welan gum production strain ATCC31555 into the seed medium, and cultivate at 30°C for 15 hours to obtain the seed solution; wherein the seed medium (mass concentration %): glucose 1%, peptone 1% , yeast powder 0.5%, K 2 HPO 4 0.2%, MgSO 4 0.01%, initial pH7.2;

[0055] Step 4, welan gum fermentation: inoculate the seed solution obtained in step 3 into a 10L fermenter equipped with 6L of the fermentation medium obtained in step 2 to f...

Embodiment 3

[0064] Step 1, preparing hydrolyzed sugar solution: pretreating and enzymatically hydrolyzing tapioca starch to obtain cassava hydrolyzed sugar solution with a glucose content of 4%;

[0065] Step 2, preparation of fermentation medium: take 7L of the hydrolyzed sugar solution obtained in step 1 as a carbon source, and add 0.4% (quality) beef extract, 0.25% (quality) K 2 HPO 4 , 0.1% (mass) MgSO 4 , 0.5 ‰ (quality) sodium dodecylsulfonate and 0.2 (quality) ‰ foam enemy made fermentation medium, initial pH 7.0;

[0066] Step 3, preparation of seed solution: inoculate the activated welan gum production strain ATCC31555 into the seed medium, and cultivate at 32°C for 14 hours to obtain the seed solution; wherein the seed medium (mass concentration %): glucose 1%, peptone 1% , yeast powder 0.5%, K 2 HPO 4 0.2%, MgSO 4 0.01%, initial pH7.5;

[0067] Step 4, Welan Gum Fermentation: Inoculate the seed liquid obtained in Step 3 into the fermentation medium for fermentation to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com