Flexible finishing machining device for hole surfaces

A finishing and flexible technology, which is applied in the field of non-free abrasive tool finishing on the surface of the hole, finishing on the surface of the hole, and flexible finishing on the surface of the hole. Due to the large space and the need for a tensioning mechanism, the effects of small footprint, convenient control and uniformity are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

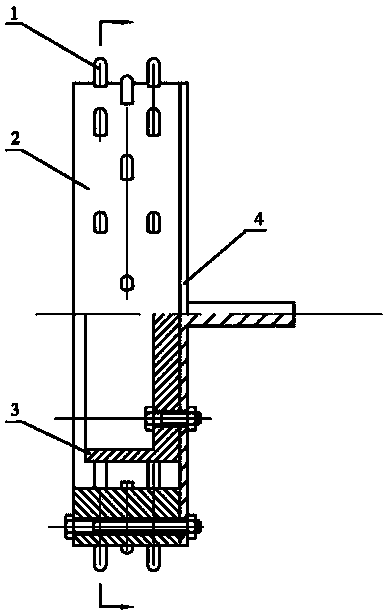

[0014] A hole surface flexible finish processing device, comprising a whetstone stick 1, a bracket 2, a mandrel 3, a cover plate 4 and a top sleeve 5, the bracket 2, the mandrel 3 and the cover plate 4 are connected together by bolts, the Oilstone rod 1 root is covered with top cover 5, is placed in the radial hole on the support, and it can expand and contract along radial hole.

[0015] Put the whole device into the hole to be processed, and start the motor at the same time, and the motor transmits the torque to the bracket 2 through the coupling. After the support 2 rotates and the speed reaches a certain value, the whetstone rod 1 placed in the radial hole of the support 2 acts on the surface of the hole with a certain pressure to achieve smoothing of the surface of the hole. If the automatic feeding device is added, the finishing process of the entire hole surface can be realized.

[0016] The outer diameter and inner diameter of the bracket 2 and the outer diameter of t...

Embodiment approach 2

[0023] A hole surface flexible finish processing device, the outer diameter of the bracket 2 is Φ160mm, the inner diameter of the bracket 2 is Φ120mm, the outer diameter of the mandrel 3 is Φ80mm, and the mesh number of the oilstone rod is 320. The specific steps are as follows:

[0024] 1. Place the hole surface finishing device in the hole to be processed.

[0025] 2. Turn on the power, turn on the governor, and set the speed value of support 2 to 500r / min through the governor.

[0026] 3. Start the flexible finishing device, the support 2 starts to rotate and process the surface of the hole.

[0027] 4. After processing, take out the device.

[0028] The surface roughness value after testing and processing can reach Ra0.3μm.

Embodiment approach 3

[0030] A hole surface flexible finish processing device, the outer diameter of the bracket 2 is Φ160mm, the inner diameter is Φ120mm, the outer diameter of the mandrel 3 is Φ80mm, and the mesh number of the oilstone rod 1 is 320. The specific steps are as follows:

[0031] 1. Place the hole surface finishing device in the hole to be processed.

[0032] 2. Turn on the power, turn on the governor, and set the speed value of support 2 to 800r / min through the governor.

[0033] 3. Start the flexible finishing device, the support 2 starts to rotate and process the surface of the hole.

[0034] 4. After processing, take out the device.

[0035] After testing, the surface roughness value can reach Ra0.25μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com