Punched felt with enhanced key parts of base cloth

A technology of key parts and needle-punched felt, which is applied to the field of reinforcing needle-punched felt in key parts of base fabric, can solve the problem of waste of material cost, etc., and achieve the effect of prolonging the life of the filter bag, prolonging the service life and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

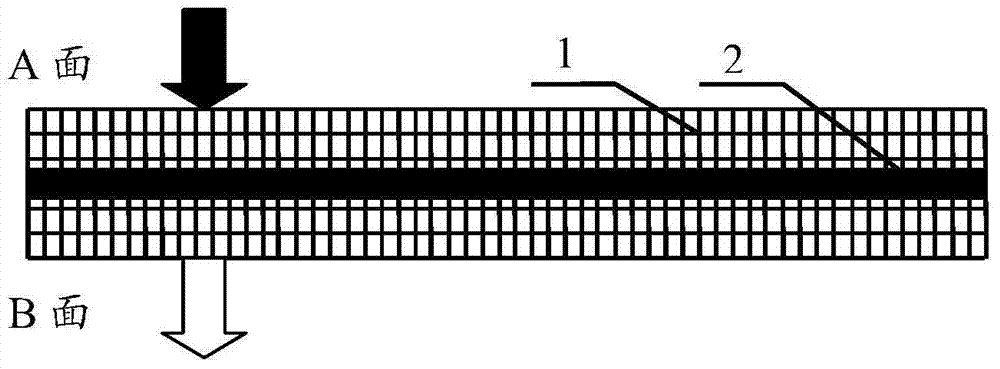

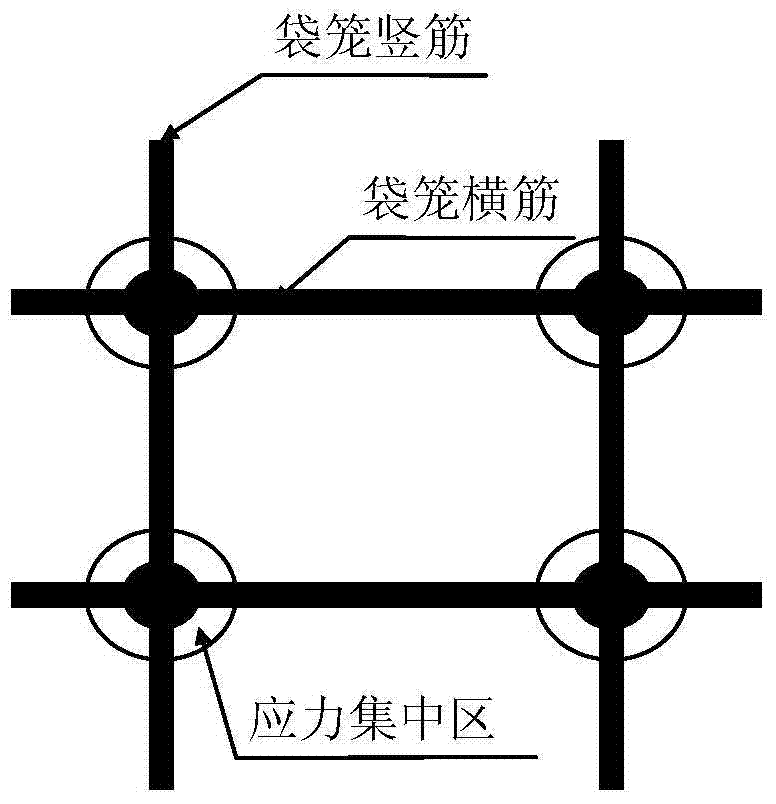

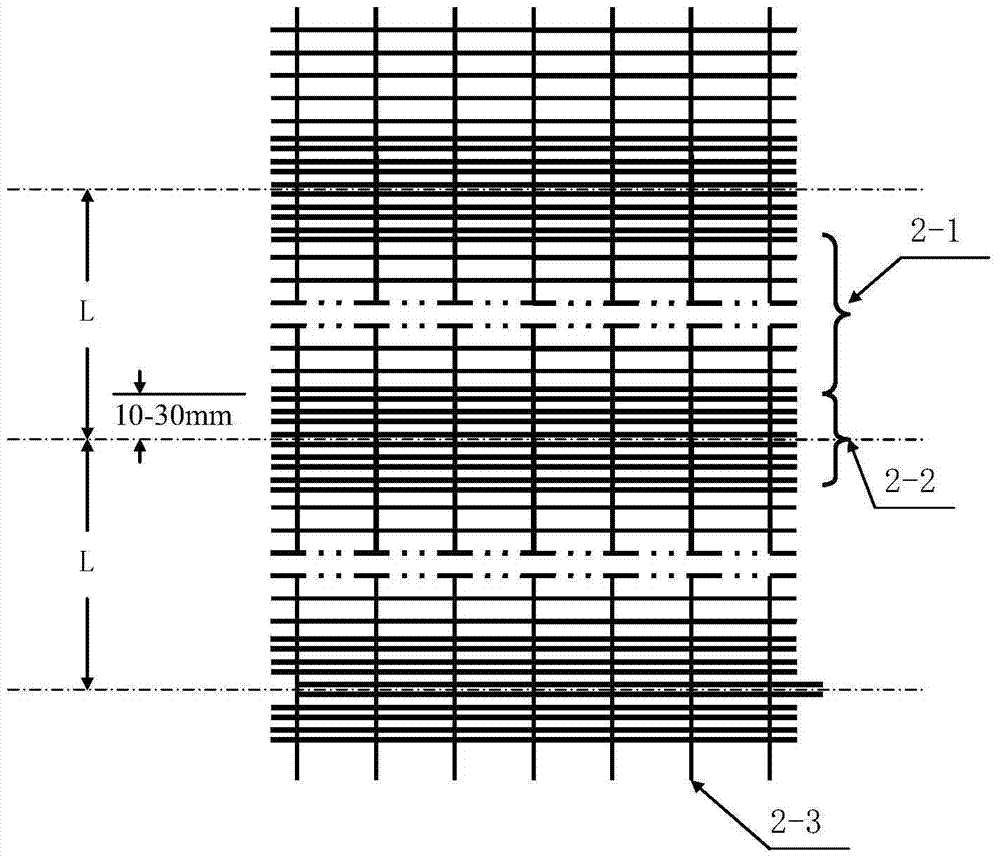

[0023] see Figure 1~4 , the embodiment of the present invention is made up of fibrous layer 1 and base cloth 2; : 4, 7: 3, 8: 2, 9: 1 blended in equal proportions, the fiber material can be PPS fiber, PTFE fiber, P84 fiber, glass fiber or other materials. The base fabric 2 is composed of transverse yarns 2-1, reinforcing transverse yarns 2-2 and longitudinal yarns 2-3, and the yarn material can be PPS fiber, PTFE fiber, P84 fiber, glass fiber or other materials. The base fabric 2 can be made of yarns of one material, and the reinforcing transverse yarns 2-2 are densely arranged within the range of 10-30 mm above and below the horizontal ribs of the matching bag cage; Within the range of 10 to 30 mm above and below the cross bars of the cage, the reinforcement transverse yarn 2-2 is made of a material with better corrosion resistance and (or) strength (such as PTFE long fiber).

[0024] Compared with the existing felt cloth, the yarn of the base cloth and the bag cage are ma...

Embodiment 2

[0027] Similar to Example 1, the difference is that the fiber layer is made of PTFE fiber, and the yarn material is P84 fiber.

Embodiment 3

[0029] Similar to Example 1, the difference is that the fiber layer is made of P84 fiber, and the yarn material is PTFE fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com