Milk powder favorable for sleep and preparation method thereof

A technology of milk powder and sleep, which is applied in the field of milk powder that helps sleep and its preparation, and can solve problems such as the inability to fortify magnesium in modulated milk and human health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

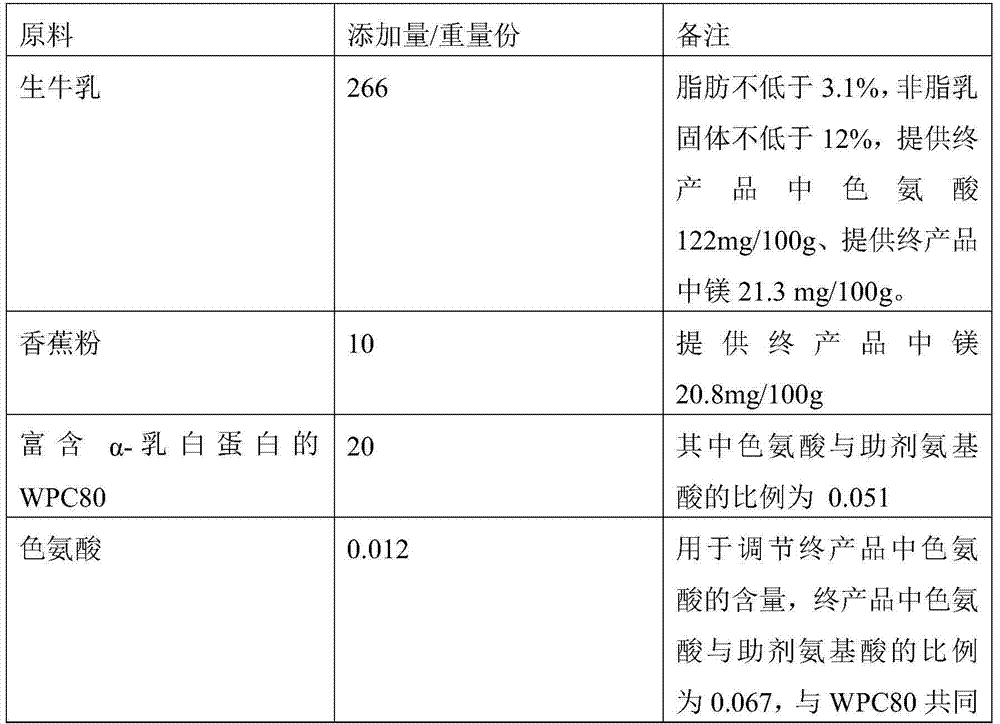

[0031] The recipe looks like this:

[0032]

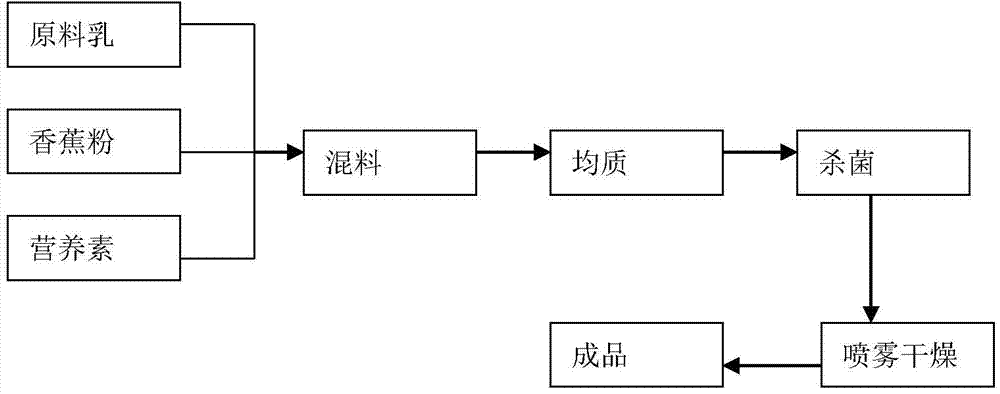

[0033] see figure 1 , the milk powder production process steps are as follows:

[0034] 1) Mix raw milk, banana powder, nutrients (dissolved in warm water), and vegetable oil at 45°C. Nutrients here include vitamin B 6 , Magnesium agent (magnesium sulfate) and other substances.

[0035] 2) Homogenize the feed liquid at 60°C and 20MPa.

[0036] 3) The homogenized feed liquid is sterilized and concentrated to a feed liquid concentration of 50%, and the sterilization conditions are 85°C and 16s.

[0037] 4) Spray-dry the concentrated material liquid, spray-drying conditions: the inlet air temperature is controlled between 150-185°C, and the exhaust air temperature is controlled between 80-95°C. The powder coming out of the drying tower is dried again in the fluidized bed (first stage) and then cooled to 25-30°C in the fluidized bed (secondary stage). At the same time, mix the soybean lecithin with the carrier, heat it to 60-6...

Embodiment 2

[0041] The recipe looks like this:

[0042]

[0043]

[0044] The process steps of milk powder production are as follows:

[0045] 1) Mix raw milk, banana powder, nutrients (dissolved in warm water), and vegetable oil at 45°C.

[0046] 2) Homogenize the feed liquid at 60°C and 20MPa.

[0047] 3) The homogenized feed liquid is sterilized and concentrated to a feed liquid concentration of 50%, and the sterilization conditions are 85°C and 16s.

[0048] 4) Spray-dry the concentrated material liquid, spray-drying conditions: the inlet air temperature is controlled between 150-185°C, and the exhaust air temperature is controlled between 80-95°C. The powder coming out of the drying tower is dried again in the fluidized bed (first stage) and then cooled to 25-30°C in the fluidized bed (secondary stage). At the same time, mix the soybean lecithin with the carrier, heat it to 60-65°C, and evenly disperse it on the surface of the powder under the action of compressed air, so th...

Embodiment 3

[0052] The recipe looks like this:

[0053]

[0054]

[0055] The process steps of milk powder production are as follows:

[0056] 1) Mix raw milk, banana powder, nutrients (dissolved in warm water), and vegetable oil at 45°C.

[0057] 2) Homogenize the feed liquid at 60°C and 20MPa.

[0058] 3) The homogenized feed liquid is sterilized and concentrated to a feed liquid concentration of 50%, and the sterilization conditions are 85°C and 16s.

[0059] 4) Spray-dry the concentrated material liquid, spray-drying conditions: the inlet air temperature is controlled between 150-185°C, and the exhaust air temperature is controlled between 80-95°C. The powder coming out of the drying tower is dried again in the fluidized bed (first stage) and then cooled to 25-30°C in the fluidized bed (secondary stage). At the same time, mix the soybean lecithin with the carrier, heat it to 60-65°C, and evenly disperse it on the surface of the powder under the action of compressed air, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com