Preparation method of natural graphite composite N-doped carbon nanofibers webs cathode material

A technology of natural graphite and negative electrode materials, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of low compaction density specific surface area, poor structural stability, low compaction density, etc., to promote rapid formation, The effect of improving compaction density and energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

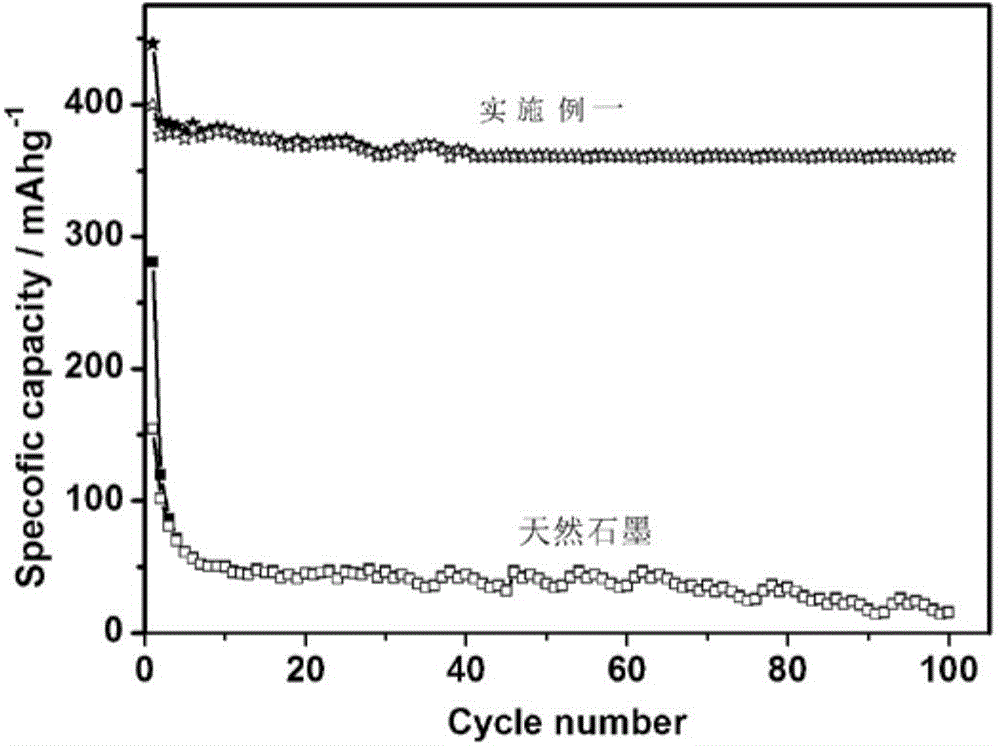

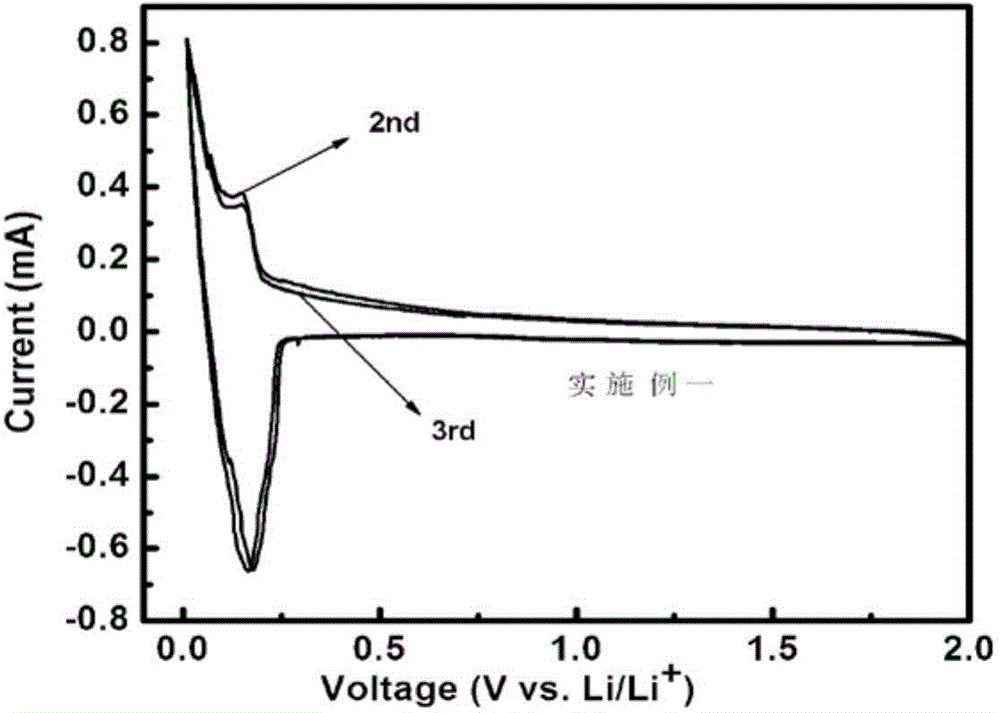

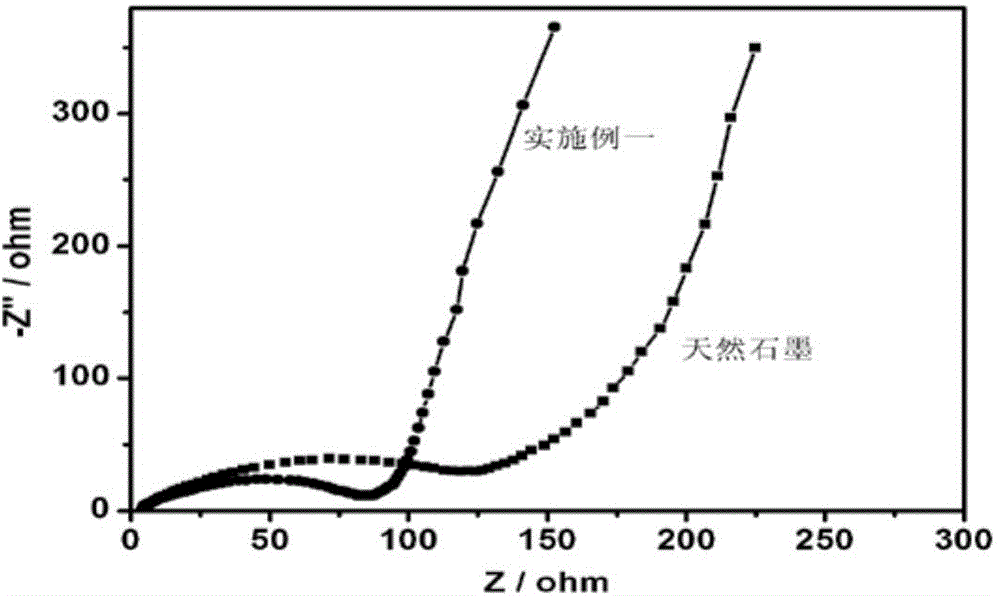

Embodiment 1

[0036] A preparation method of natural graphite composite nitrogen-containing carbon fiber net negative electrode material:

[0037]Add the activated natural flake graphite to the mixture of emulsified pitch, carboxymethyl starch, and deionized water, mix evenly, add deionized water to adjust the volume percentage of insoluble solids to 75%, then spray dry, mix The mass ratio of emulsified pitch and carboxymethyl starch in the liquid is 1:2, and the ratio of the total mass of emulsified pitch and carboxymethyl starch to the mass of activated natural flake graphite is 10%:90%.

[0038] The spray-dried product was heat-treated at 1600 °C for 10 hours in an argon (0.3 L / min, normal pressure) atmosphere to obtain carbon-coated natural flake graphite. Then carbon-coated natural flake graphite and nitrogen-containing carbon fiber network, lithium carbonate, composite conductive agent (a mixture of Super P Li and conductive graphite, wherein, Super P Li: conductive graphite mass rati...

Embodiment 2

[0040] A preparation method of natural graphite composite nitrogen-containing carbon fiber net negative electrode material: except that the ratio of the total mass of emulsified pitch and carboxymethyl starch to the mass of activated natural flake graphite is changed to 7%:93%, the rest All with embodiment 1.

Embodiment 3

[0042] A preparation method of natural graphite composite nitrogen-containing carbon fiber net negative electrode material: except that the ratio of the total mass of emulsified pitch and carboxymethyl starch to the mass of activated natural flake graphite is changed to 15%: 85%, the rest All with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com