Method for measuring electric conduction loop resistance of circuit breaker

A technology of loop resistance and conductive loop, applied in the direction of measuring resistance/reactance/impedance, measuring electrical variables, measuring devices, etc., can solve problems such as poor contact between wire clips and circuit breakers, prolonged power outages, and staff falling from high altitudes, etc. Achieve the effect of improving work efficiency and economic benefits, avoiding accidents and reducing power outages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

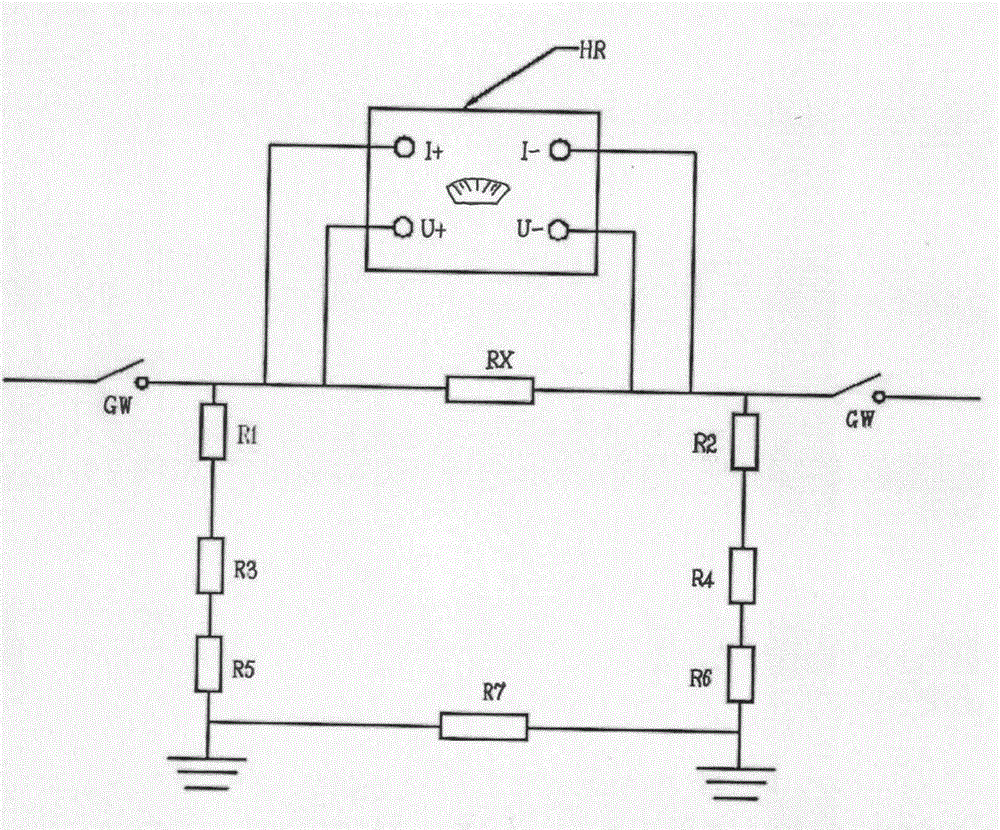

[0014] Attached figure 1 In the test method shown, without removing the grounding wires on both sides of the circuit breaker, directly connect the + , U+ are connected to one side of the tested resistance RX, and I- and U- of the HR loop resistance tester are connected to the other side of the tested resistance RX for testing.

[0015] The current misunderstanding of the circuit breaker conductive loop resistance test is: when performing a normal test, the grounding wires on both sides of the RX must be removed. It is considered that the grounding wires should not be removed. When the HR loop resistance tester outputs current, because the HR shell is grounded, current will flow through I + -R1-R3-R5-R7-R6-R4-R2-I ﹣ Flow back to HR loop resistance tester or directly to ground without flowing through RX.

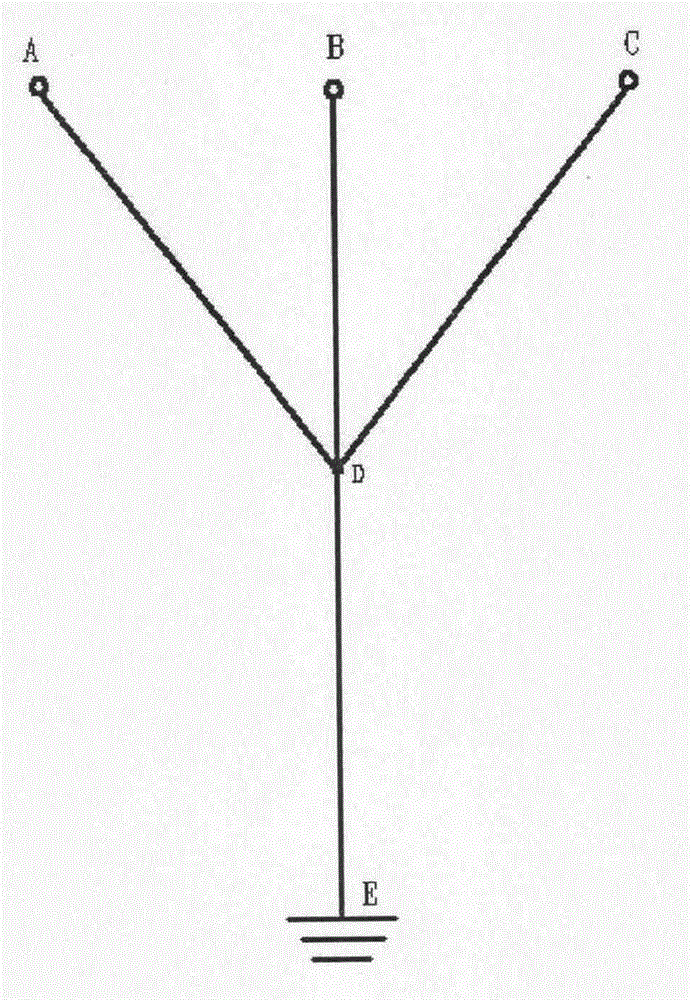

[0016] Attached below figure 1 , 2 Describe the circuit breaker loop resistance test without disconnecting the ground wire. Such as figure 1 As shown in Fig. 1 , it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com