Sample preparation method for uniformly distributing trace components in solid block matrix

A technology of evenly distributed trace components, applied in the field of sample preparation, can solve the problems of metal samples that cannot be melted directly, high sample preparation cost, and high melting temperature, so as to reduce particle size effect and mineral effect, reduce sample preparation cost, The effect of simple sample preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

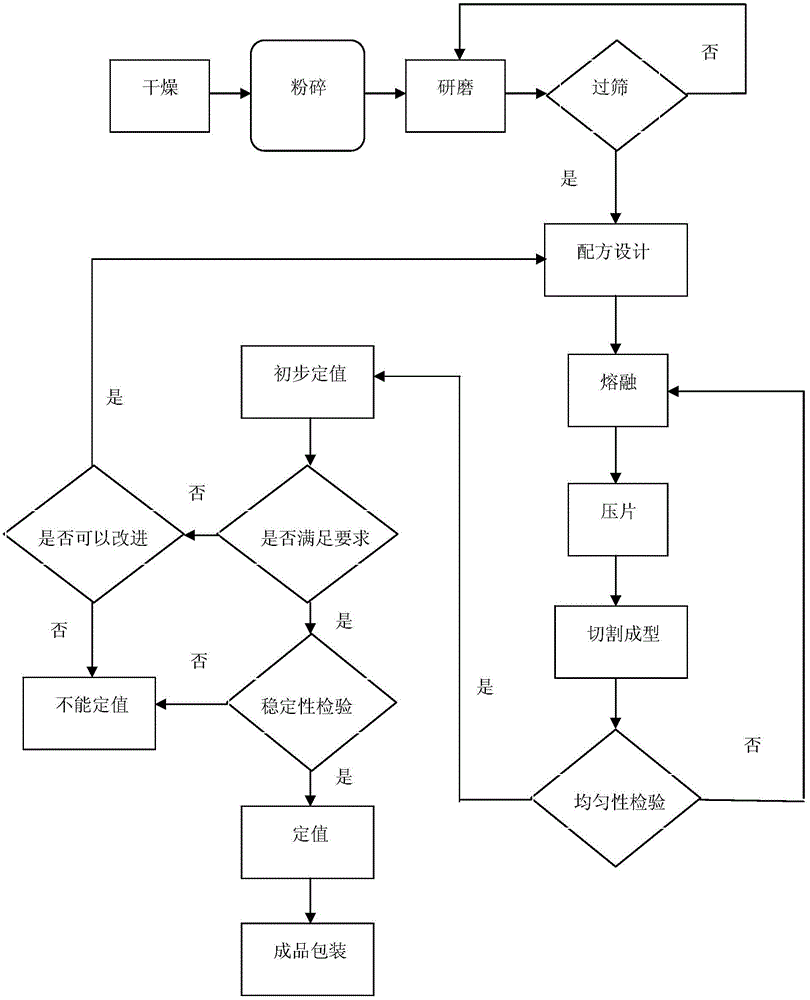

Method used

Image

Examples

Embodiment 1

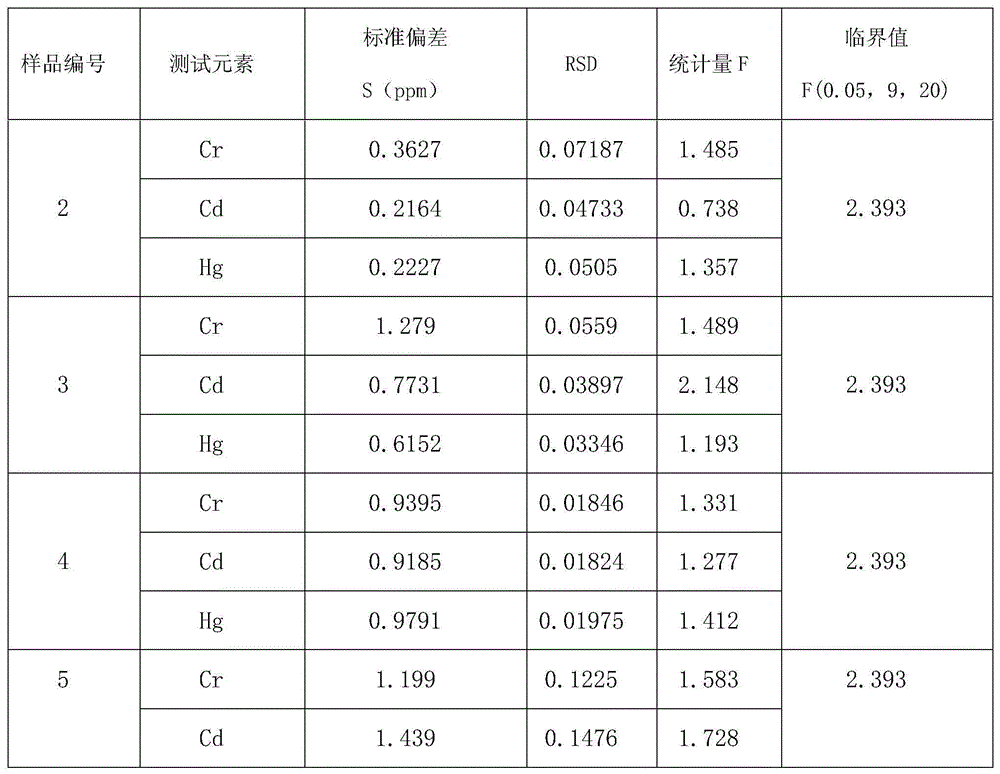

[0027] Taking the preparation of samples containing trace amounts of heavy metals chromium, cadmium, and mercury as an example, the process is as follows:

[0028] 1) Take potassium chromate, cadmium stearate, and mercury acetate containing the target elements chromium, cadmium, and mercury, dry them at 60°C for 24 hours, grind them, and pass them through a 200-mesh sieve.

[0029] 2) According to the designed formula composition, accurately weigh 6 parts of ABS matrix, each weighing 150 grams, and weigh 5 parts each of potassium chromate, cadmium stearate, and mercury acetate of different weights after sieving; heat Melt the ABS matrix at 115-125°C, and add the weighed trace components to the melted ABS matrix under stirring conditions, and stir and mix at 115-125°C for 2-3 hours, so that the trace components Distribute evenly in the ABS matrix to obtain a molten mixture of trace components-ABS matrix; each molten mixture after melt mixing is labeled as ABS-1, ABS-2, ABS-3, A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com