Novel N-acetylneuraminic acid-producing escherichia coli engineering bacteria as well as construction method and application thereof

A technology of acetylneuraminic acid and Escherichia coli, applied in the field of bioengineering, can solve the problems of high cost, high production cost of sialic acid, and limitation of large-scale popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

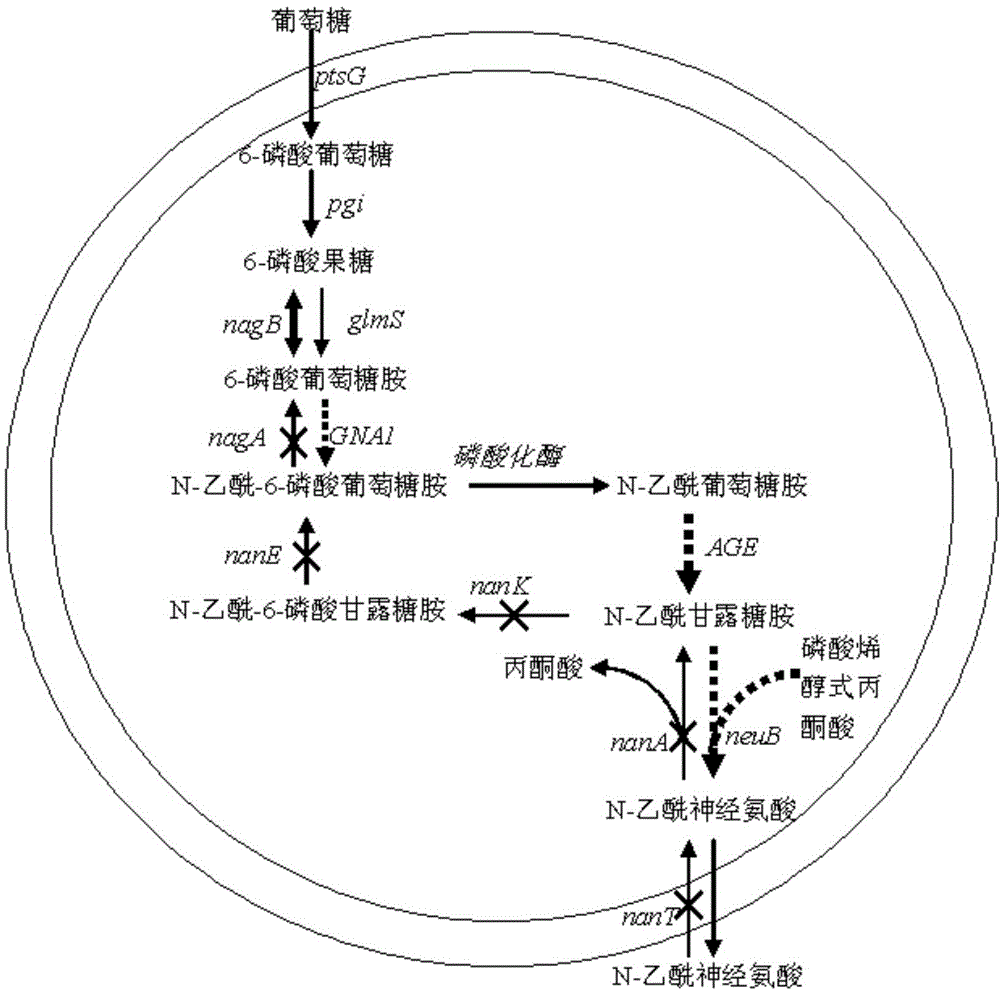

[0040] Embodiment 1: Construction of high-yield N-acetylneuraminic acid genetically engineered bacteria

[0041] 1. Using the RED recombination method to inactivate the nagA gene and nanATEK gene cluster in the strain, the specific steps are as follows:

[0042] 1. Knockout of nagA gene

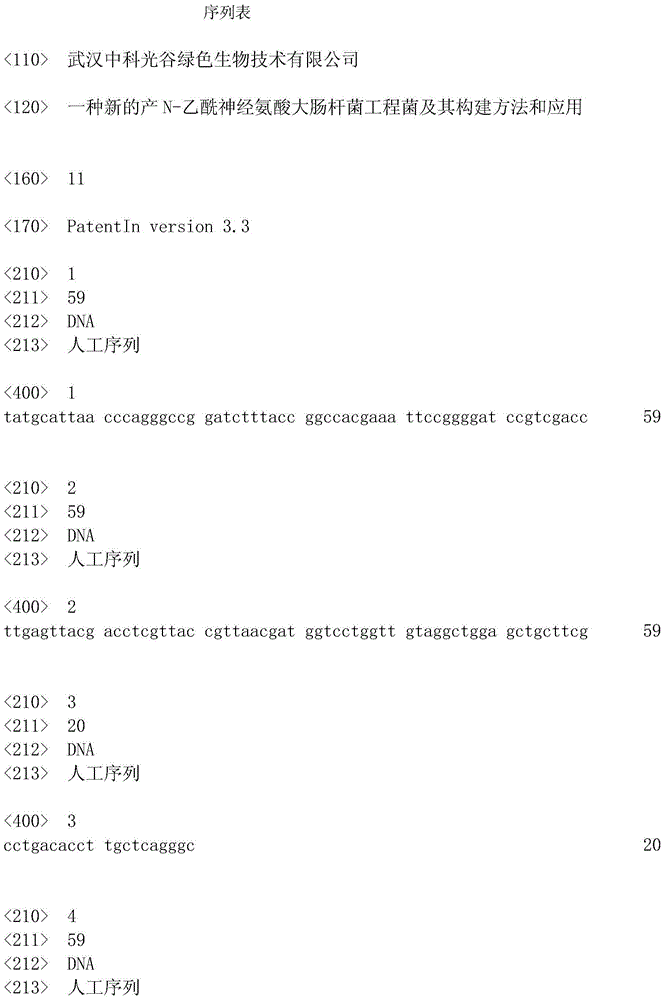

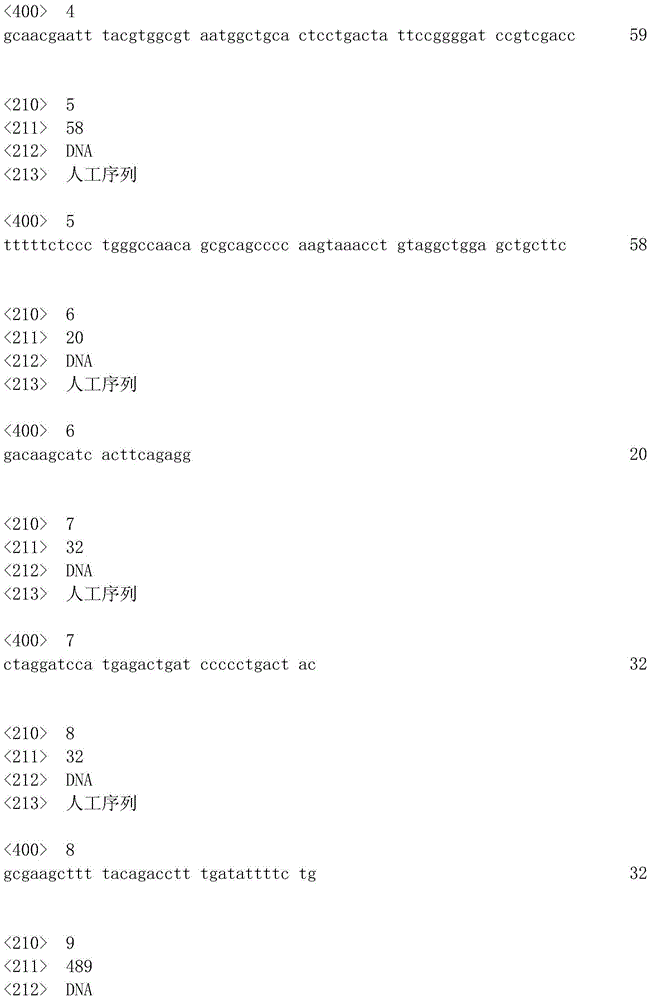

[0043] 1) According to the sequence of Escherichia coli BL21 (DE3) (Invitrogen Company) genome (Genbank No.CP001509), design primers: upstream primer F-KO-nagA:

[0044] TATGCATTAACCCAGGGCCGGATCTTTACCGGCCACGAAATTCCGGGGATCCGTCGACC (shown in SEQ ID NO.1) and downstream primer R-KO-nagA:

[0045] TTGAGTTACGACCTCGTTACCGTTAACGATGGTCCTGGTTGTAGGCTGGAGCTGCTTCG (shown in SEQ ID NO. 2).

[0046] Using the primers F-KO-nagA and R-KO-nagA, using the plasmid pIJ773 as a template, and using commercial PCR reagents, the DNA fragments were amplified by PCR and purified for future use.

[0047] 2) The RED recombinase expression plasmid vector pKD46 was transformed into Escherichia coli BL21(DE3) by electri...

Embodiment 2

[0111] Example 2 Glucose is used as carbon source to ferment and produce N-acetylneuraminic acid

[0112] 1. Seed and fermentation medium (1L):

[0113] (NH 4 ) 2 SO 4 4g / L; KH 2 PO 4 6g;K 2 HPO 4 ·3H 2 O8g; MgSO 4 ·7H 2 O0.25g; glucose 5g, trace elements 10ml.

[0114] Among them, trace elements are: manganese sulfate 100mg / L; zinc chloride 70mg / L; sodium molybdate 35mg / L; boric acid 60mg / L; cobalt chloride 200mg / L; copper sulfate 29.28mg / L; L; concentrated hydrochloric acid (37%) 0.9ml / L.

[0115] Feed solution: 500g / L glucose.

[0116] 2. Fermentation process:

[0117] 1) Pick a single colony and place it in a 4ml LB test tube, and incubate at 37°C for 8 hours.

[0118] 2) Inoculate 2ml of first-grade seeds into 200ml of seed medium and incubate at 37°C for 8-10 hours.

[0119] 3) Secondary seeds are inoculated in a fermenter with a liquid volume of 3.5L, at 37°C, with a stirring speed of 300-800 rpm, dissolved oxygen is kept above 30%, and the pH is controll...

Embodiment 3

[0123] Example 3 Glycerol is used as carbon source to ferment and produce N-acetylneuraminic acid

[0124] Replace glucose with glycerol of 20g / L, other components of fermentation medium are the same as embodiment 2, and feeding medium is 600g / L glycerol;

[0125] The fermentation process is the same as in Example 2.

[0126] Finally, after about 80 hours of fermentation, the concentration of N-acetylneuraminic acid produced by CASOV-1 can reach 30g / L; the concentration of N-acetylneuraminic acid produced by CASOV-2 can reach 5g / L.

[0127] The above culture results show that the genetically engineered bacteria constructed by metabolic engineering technology, especially CASOV-1, has the ability to produce N-acetylneuraminic acid and has the potential for industrialization.

[0128]

[0129]

[0130]

[0131]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com