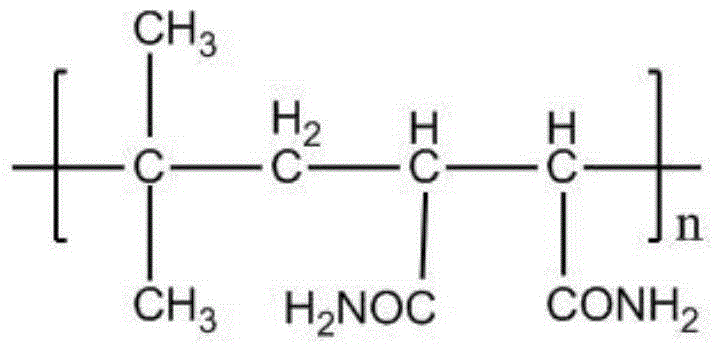

Polyisobutene butylene amide, method for its preparation and use of the amide to prepare microlubricant

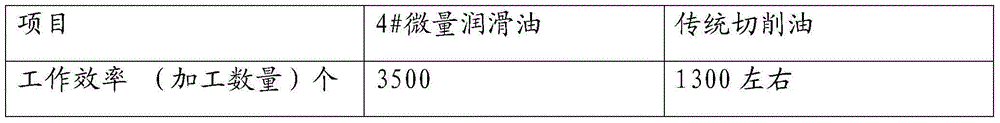

A technology of polyisobutylene butylene amide and micro-lubricant, which is applied in the field of lubrication to achieve good water solubility, avoid cumbersome processes, and good lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

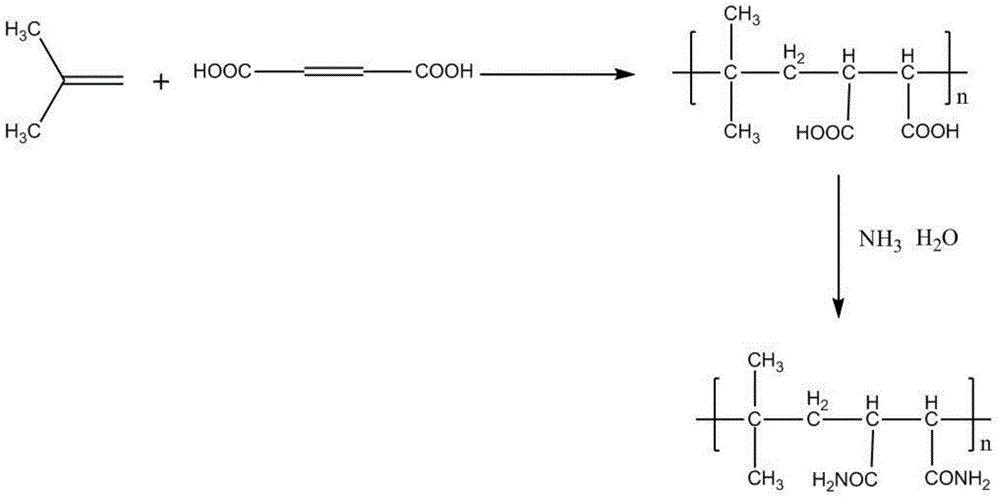

Method used

Image

Examples

Embodiment 1

[0039] 1# micro lubricant

[0040] Step 1: Put 148.24kg (2000mol) of isobutanol and 98.06kg (1000mol) of maleic anhydride (maleic anhydride) into the polymerization kettle respectively, and fully stir;

[0041] Step 2: Put 0.74kg of initiator dibenzoyl peroxide (BPO) into the polymerization kettle;

[0042] Step 3: Filling with nitrogen to discharge the air in the polymerization kettle;

[0043] Step 4: heat up to 80°C while stirring;

[0044] Step 5: Slowly fill 56.11kg (1000mol) of isobutylene gas into the mixed liquid in the polymerization kettle, and keep stirring at a constant temperature;

[0045] Step 6: Keep stirring at constant temperature for 12 hours after filling the isobutene gas;

[0046] Step 7: adding ammonia water to the polymerization kettle;

[0047] Step 8: Fully stir the reaction, observe the pH value, and stop adding ammonia water when the pH value of the solution reaches 8.5;

[0048] Step 9: Elevate the temperature and reduce pressure to remove wat...

Embodiment 2

[0051] 2# micro lubricant

[0052] Step 1: Put 138.21kg (3000mol) of ethanol and 116.07kg (1000mol) of maleic acid (maleic acid) into the polymerization kettle respectively, and fully stir;

[0053] Step 2: Put 0.51kg initiator diethylhexyl peroxydicarbonate (EHP) into the polymerization kettle;

[0054] Step 3: Filling with nitrogen to discharge the air in the polymerization kettle;

[0055] Step 4: heat up to 70°C while stirring;

[0056] Step 5: Slowly fill 56.11kg (1000mol) of isobutylene gas into the mixed liquid in the polymerization kettle, and keep stirring at a constant temperature;

[0057] Step 6: Keep stirring at constant temperature for 6 hours after filling the isobutene gas;

[0058] Step 7: adding ammonia water to the polymerization kettle;

[0059] Step 8: Fully stir the reaction, observe the pH value, and stop adding ammonia water when the pH value of the solution reaches 8;

[0060] Step 9: Elevate the temperature and reduce pressure to remove water, is...

Embodiment 3

[0063] 3# micro lubricant

[0064] Step 1: Put 150.25kg (2500mol) of n-propanol and 116.07kg (1000mol) of fumaric acid (fumaric acid) into the polymerization kettle respectively, and stir thoroughly;

[0065] Step 2: 0.27kg initiator azobisisobutyronitrile is dropped into the polymerization kettle;

[0066] Step 3: Filling with nitrogen to discharge the air in the polymerization kettle;

[0067] Step 4: heat up to 75°C while stirring;

[0068] Step 5: Slowly fill 56.11kg (1000mol) of isobutylene gas into the mixed liquid in the polymerization kettle, and keep stirring at a constant temperature;

[0069] Step 6: Keep stirring at constant temperature for 18 hours after filling the isobutene gas;

[0070] Step 7: adding ammonia water to the polymerization kettle;

[0071] Step 8: Fully stir the reaction, observe the pH value, and stop adding ammonia water when the pH value of the solution reaches 8.1;

[0072] Step 9: Elevate temperature and reduce pressure to remove water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com