A method to improve the removal rate of biogas slurry n, p and cod based on falling water ecological floating bed

An ecological floating bed, removal rate technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high energy consumption, environmental pollution, high cost, and achieve low investment, The effect of improving the processing effect and easy management

Inactive Publication Date: 2015-11-25

SOUTHWEST UNIV

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the embodiments of the present invention is to provide a method for improving the removal rate of biogas slurry N, P, and COD based on the falling water ecological floating bed, aiming at solving the problems of large energy consumption, high cost and easy environmental pollution in the existing biogas slurry treatment method. pollution problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

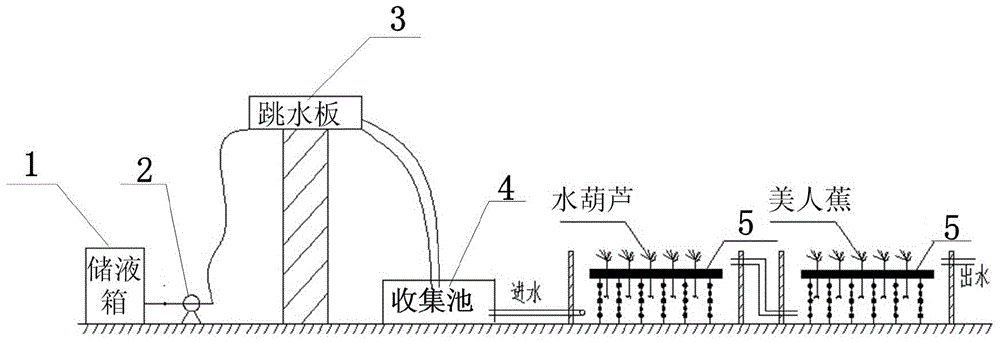

[0037] Embodiment: through the technology of the present invention, under the condition that the water drop height is 70cm, the water drop width is 25cm, the water drop depth is 20cm, the floating bed plants are water hyacinth and canna, and the filler is the combined filler, the TN, TP, COD in the biogas slurry are The removal rates can reach 83.37%, 79.35% and 87.87%, respectively. .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

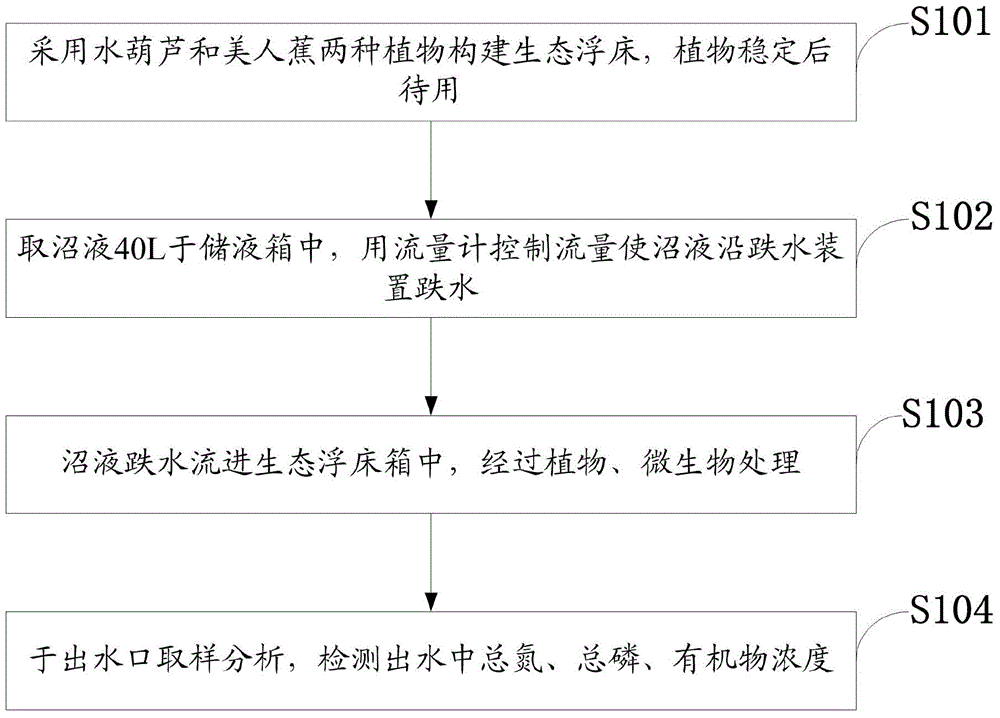

The invention discloses a method for increasing the N (Nitrogen), P (Phosphorus) and COD (Chemical Oxygen Demand) removal rate of biogas liquid based on a water-dropping ecological floating bed. The method comprises the following steps: constructing the ecological floating bed by adopting two species of plants, namely water hyacinth and canna, and stabilizing the plants for later use; putting 40L of biogas liquid in a liquid storage tank, and controlling flow rate by using a flowmeter to enable the biogas liquid to drop along a water dropping device; enabling dropping biogas liquid to flow into an ecological floating bed tank for plant and microorganism treatment; sampling at a water outlet, analyzing, and detecting the concentration of total nitrogen, total phosphorus and organic substances in outlet water. According to the method, water-dropping oxygenation and the ecological floating bed are adopted as two different wastewater treatment technologies; oxygen in air is transferred into water by dropping water, so as to maintain the normal metabolism of microorganisms in the water; the removal of nutritive salts such as nitrogen and phosphorus and organic substances, from the water is realized through the ecological floating bed, so that the biogas liquid treatment effect is improved effectively; the content of dissolved oxygen in sewage is increased, the operating method is simple, and the treatment cost is low.

Description

technical field [0001] The invention belongs to the technical field of biogas slurry treatment, and in particular relates to a method for improving the N, P and COD removal rates of biogas slurry based on a falling water ecological floating bed. Background technique [0002] The disposal of biogas slurry after anaerobic fermentation in the promotion and application of large and medium-sized biogas projects has become one of the important factors restricting its development. Biogas slurry is a high-concentration organic wastewater containing a large amount of nitrogen, phosphorus and organic matter. If the biogas slurry is not effectively treated and discharged at will, it will lead to the loss of nitrogen and phosphorus, causing serious environmental problems such as water eutrophication and agricultural non-point source pollution. Therefore, the effective treatment of biogas slurry is an urgent problem to be solved. [0003] The treatment of biogas slurry has the followin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F3/32

Inventor 陈玉成王莉玮杨志敏何为媛陈正杰

Owner SOUTHWEST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com