Method for preparing chemical raw materials by using alkali method to process potassium fertilizer intermediate

A technology for chemical raw materials and intermediates, which is applied to the field of alkali treatment of potassium fertilizer intermediates to obtain chemical raw materials, can solve the problem that the comprehensive utilization of potassium feldspar ore resources is insufficient to produce chemical raw materials, the ratio of input to output is increased, and potassium-containing rocks are wasted. resources and other issues, to achieve the effect of increasing the value of additional products, reducing the ratio of input and output, and alleviating the shortage problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

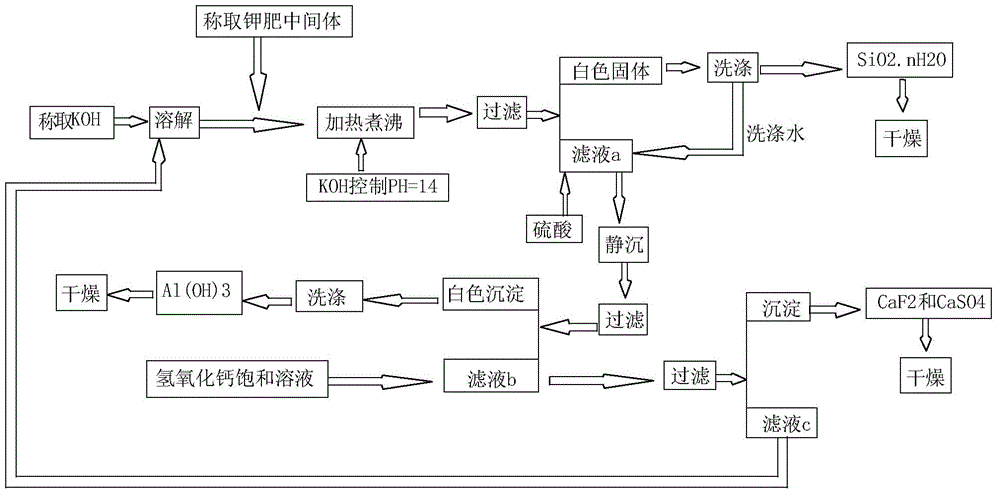

Method used

Image

Examples

Embodiment 1

[0029] Weigh 9.0g of KOH, pour it into a 100ml beaker, add distilled water to dissolve it, then weigh 3.0g of potassium fertilizer intermediate, add it to the beaker containing KOH solution and mix it, then heat it to boil, so that the boiled The volume of the solution was kept at 50ml, and the pH of the solution was controlled by KOH solution to be 14, and heated and boiled for 65 minutes. During the heating reaction, the potassium fertilizer intermediate was partially reacted and dissolved to generate a white solid substance. Then filter the reacted solution, and constantly wash the white solid with distilled water for 1h during the filtering process to obtain the white solid and filtrate a, wherein the white solid is SiO 2 ·nH 2 O, put the white solid in a drying oven and bake for 2h to get SiO 2 10H 2 O,; SiO can be obtained by baking for 4h 2 2H 2 O, extract the Si element in potassium feldspar.

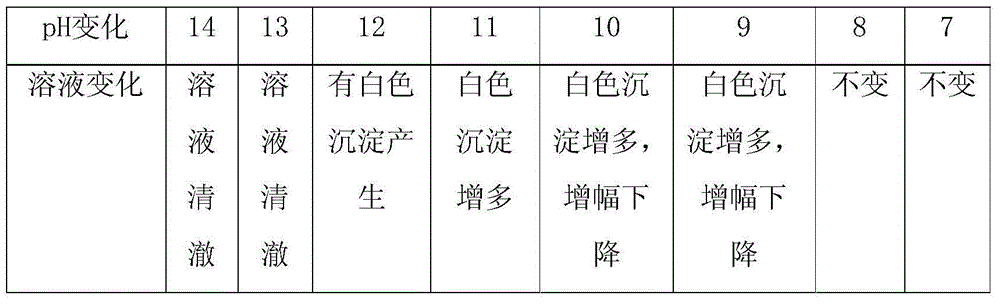

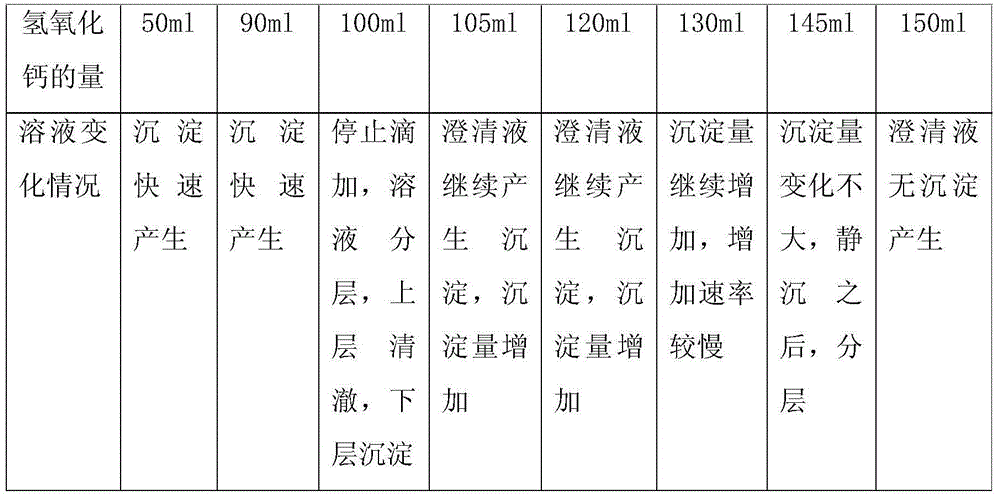

[0030] Then slowly add the filtered filtrate a with sulfuric acid with...

Embodiment 2

[0033]Weigh 6.0g of KOH, pour it into a 100ml beaker, add distilled water to dissolve it, then weigh 3.0g of potassium fertilizer intermediate, add it to the beaker where KOH is dissolved, and mix it, then heat it to boil to make the volume of the boiled solution Keep it at 50ml, and use KOH solution to control the pH of the solution to be 14, heat and boil for 75min, during the heating reaction process, part of the potassium fertilizer intermediate reacts and dissolves, and produces a white solid substance. Then filter the reacted solution, and constantly wash the white solid with distilled water for 2h during the filtering process to obtain the white solid and filtrate a, wherein the white solid is SiO 2 ·nH 2 O, put the white solid in a drying oven and bake for 2.5h to get SiO 2 10H 2 O; SiO can be obtained by baking for 3.5h 2 2H 2 O, to extract the Si element in potassium feldspar.

[0034] Then slowly add the filtered filtrate a with sulfuric acid with a molar conce...

Embodiment 3

[0037] Weigh 12.0g of KOH, pour it into a 100ml beaker, add distilled water to dissolve it, then weigh 3.0g of potassium fertilizer intermediate, add it to the beaker where KOH is dissolved, and mix it, then heat and boil it to make the volume of the boiled solution Keep it at 50ml, and use KOH solution to control the pH of the solution to be 14, heat and boil for 70min, during the heating reaction process, part of the potassium fertilizer intermediate reacts and dissolves, and produces a white solid substance. Then filter the reacted solution, and constantly wash the white solid with distilled water for 1.5h during the filtering process, to obtain the white solid and filtrate a, wherein the white solid is SiO 2 ·nH 2 O, put the white solid in a drying oven and bake for 3h to get SiO 2 10H 2 O and SiO 2 2H 2 O mixture to extract the Si element in potassium feldspar.

[0038] Then slowly add the filtered filtrate a with sulfuric acid with a molar concentration of 1mol / L to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com