Portable universal type chlorine dioxide generator and its application

A chlorine dioxide and generator technology, applied in the direction of chlorine oxidation, etc., can solve the problems of transportation, inconvenient operation, low conversion rate of raw materials, complex equipment structure, etc., and achieve the effect of light weight, high conversion rate of raw materials and small volume of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

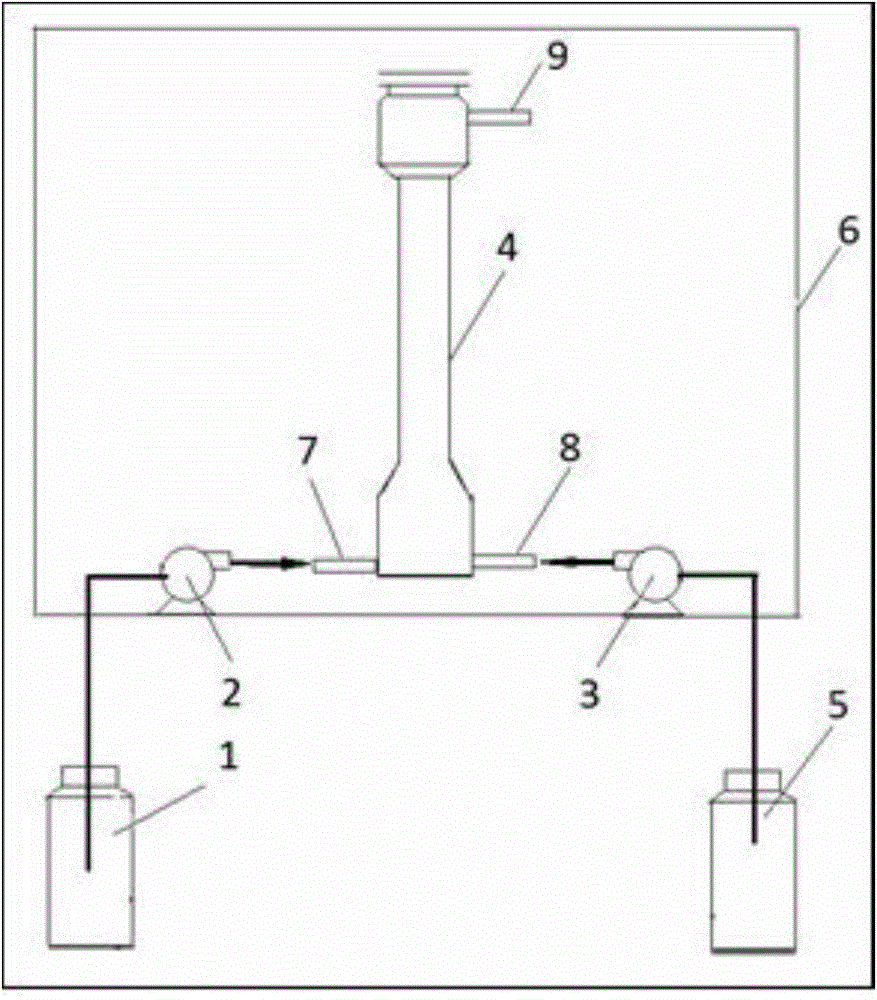

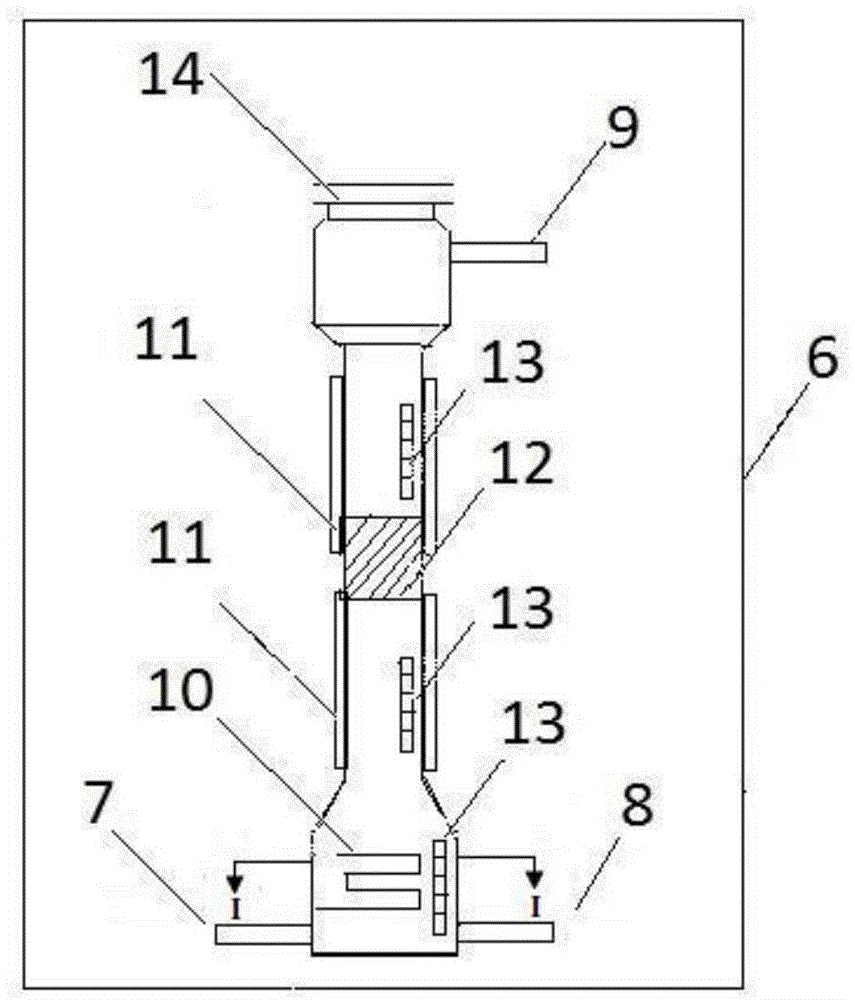

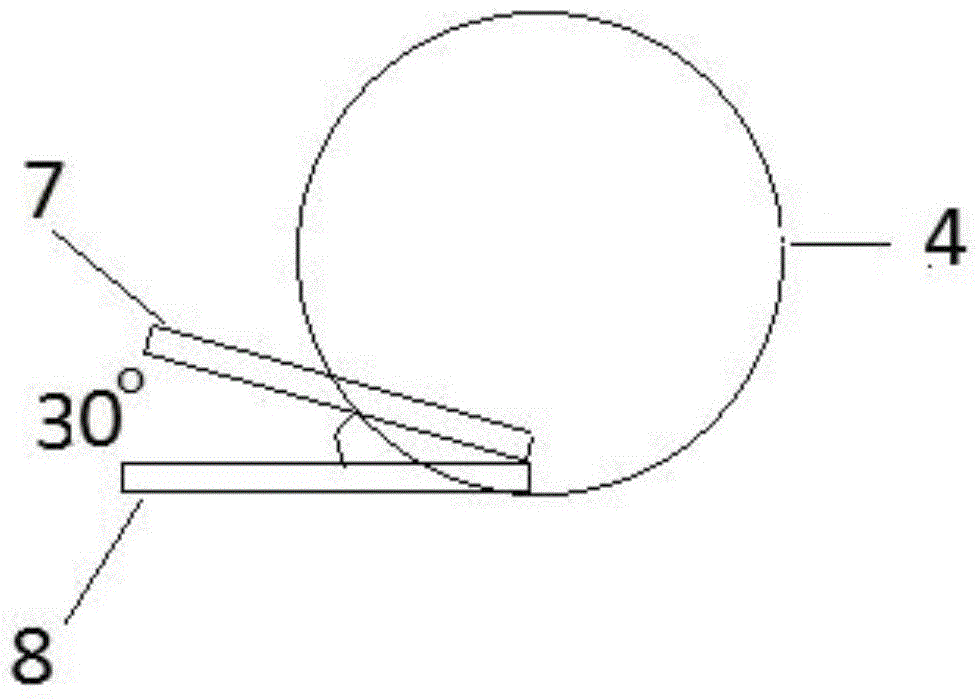

[0037] One embodiment of the present invention is that reaction raw material sodium chlorite solid and water are by the first supply unit 1, raw material pump 2, enter in the reactor 4 through the first raw material inlet pipe 7 along the tangential direction of the pipe wall of the lower part of the reactor; At the same time, the raw material sodium bisulfate solid and water enter the reactor 4 through the second raw material inlet pipe 8 by the second supply unit 5 and the raw material pump 3, and are fully mixed with the sodium chlorite at the discharge end of the first raw material inlet pipe 7. After being mixed and heated by the heater 10, the temperature rises rapidly and then enters the middle part of the reactor 4 equipped with titanium wire packing 12. The chlorine dioxide gas generated after the raw materials are fully reacted is dissolved in water to form an aqueous solution, which is directly output to the outside of the reactor box 6 through the outlet pipe 9 .

Embodiment 2

[0039] Another embodiment of the present invention reacts raw material sodium chlorate aqueous solution by the first supply unit 1, raw material pump 2, enters in the reactor 4 through the first raw material inlet pipe 7 along the pipe wall tangential direction of reactor 4 bottom; Meanwhile, The raw material hydrochloric acid enters the reactor 4 through the second raw material inlet pipe 8 from the second supply unit 5 and the raw material pump 3, fully mixes with the sodium chlorate aqueous solution at the outlet end of the first raw material inlet pipe 7, and heats up rapidly through the heater 10. After that, it enters the middle part of the reactor 4 equipped with titanium wire packing 12 . The raw materials are fully reacted to produce compound chlorine dioxide (that is, a mixture of chlorine dioxide and chlorine, usually ClO 2 :Cl 2 =2:1 (molar ratio, the reaction equation is: 2NaClO 3 +4HCl→2ClO 2 +Cl 2 +2NaCl+2H 2 O) is output to the outside of the reactor box 6...

Embodiment 3

[0041] Another embodiment of the present invention is that the reaction raw material sodium chlorite aqueous solution enters in the reactor 4 through the first raw material inlet pipe 7 along the tangential direction of the pipe wall of the lower part of the reactor by the first supply unit 1 and the raw material pump 2; Simultaneously, the raw material hydrochloric acid enters in the reactor 4 through the second raw material inlet pipe 8 by the second supply unit 5 and the raw material pump 3, fully mixes with the sodium chlorite aqueous solution at the outlet end of the first raw material inlet pipe 7, passes through the heater 10 After heating up rapidly, it enters the middle part of the reactor 4 equipped with titanium wire packing 12 . After the raw materials are fully reacted, a high-purity chlorine dioxide aqueous solution (≥98%) is output to the outside of the reactor box 6 through the outlet pipe 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com