Light MC (monomer casting) nylon carrier roller for light loads and method for manufacturing light MC nylon carrier roller

A kind of idler, light-load technology, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., can solve the problems of weak acid and alkali corrosion resistance, poor running stability, easy object adhesion, etc., to achieve strong waterproof and dustproof ability. , Good sealing performance and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

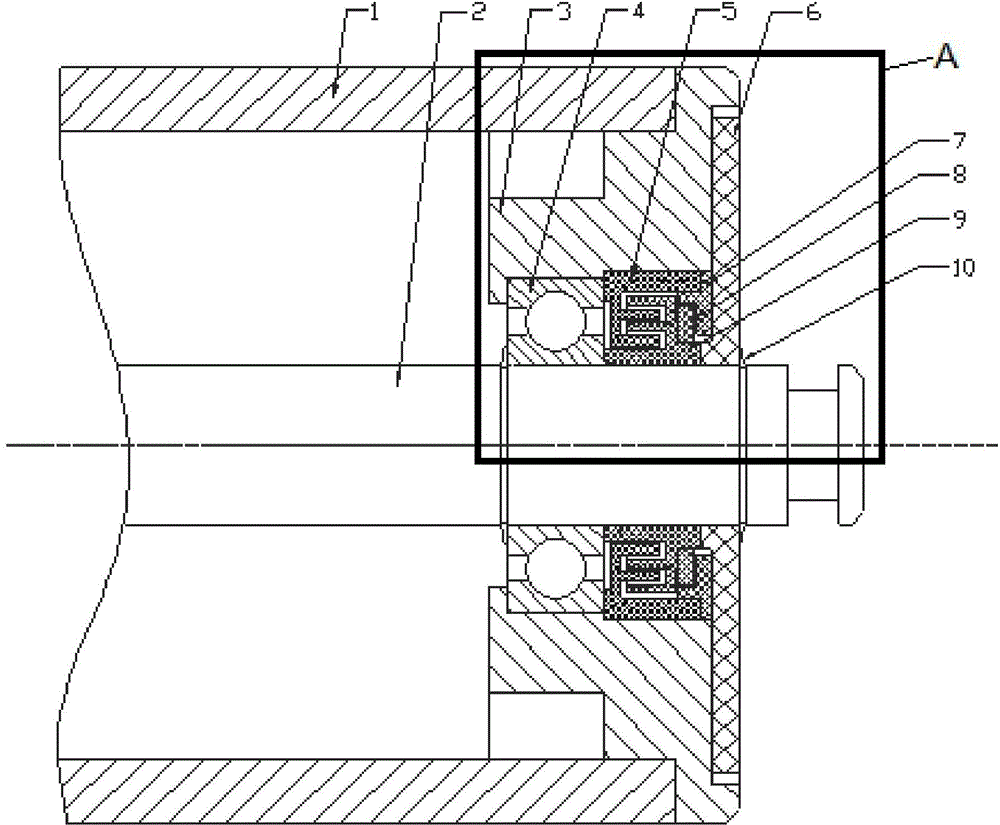

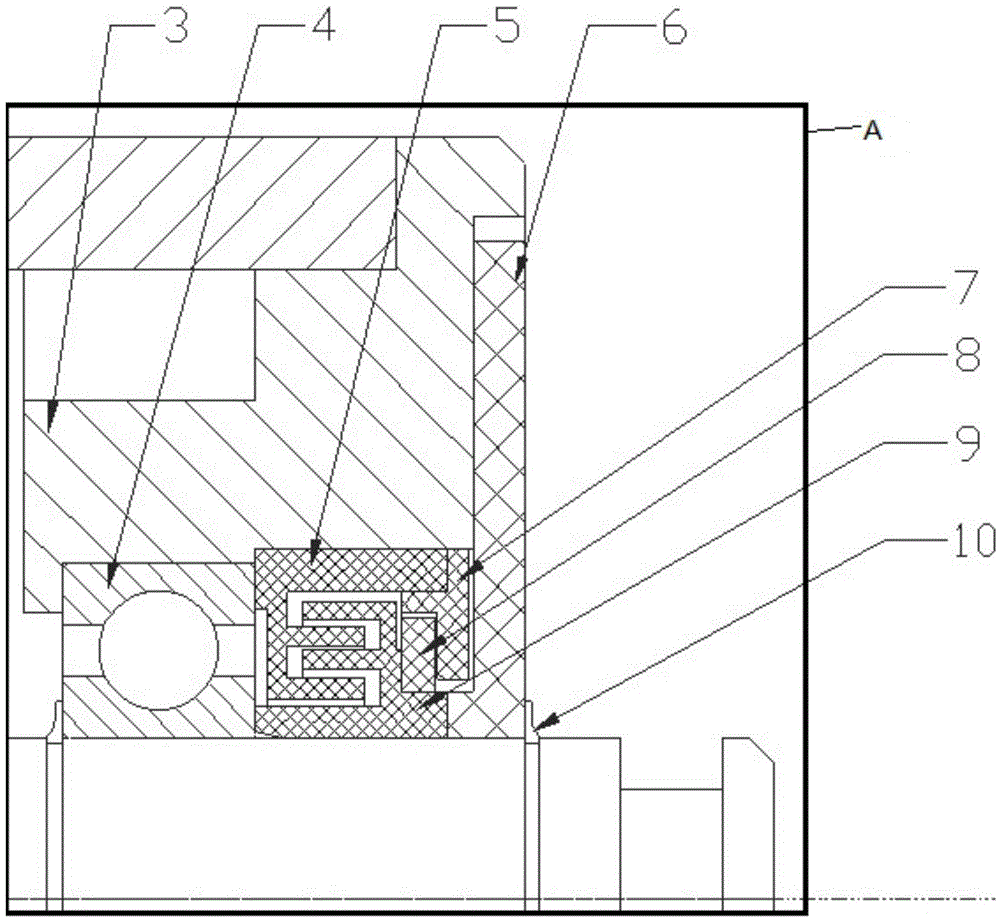

[0032] figure 1 It shows the light weight and light load MC nylon idler roller structure provided by the present invention. For ease of illustration, only the parts relevant to the present invention are shown.

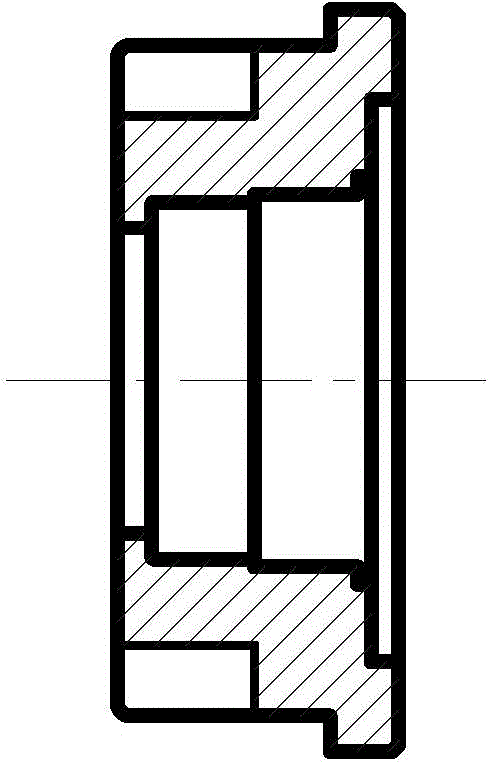

[0033] The light-weight and light-load MC nylon idler roller of the present invention includes: a roller body 1, a shaft 2, a low-stress assembly bearing seat 3, a bearing 4, an inner sealing ring 5, an anti-seizing ring 6, a dust-proof sealing card 7, and a sealing felt 8. Outer sealing ring 9 and circlip 10; bearings 4, inner sealing ring 5, outer sealing ring 9, sealing felt 8, and dust-proof sealing card 7 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com