Silver-phosphate-based composite visible light photocatalytic material and preparation method thereof

A catalytic material and silver phosphate-based technology are applied in the field of silver phosphate-based composite visible light catalytic materials and their preparation, and achieve the effects of less energy consumption, reduced preparation cost, and simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

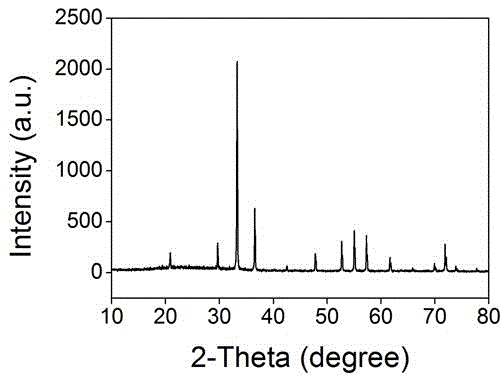

Image

Examples

Embodiment 1

[0030] Dissolve 300 mg of zinc oxide in 10 ml of deionized water and sonicate for 30 minutes to obtain a zinc oxide dispersion; weigh 0.51 g of silver nitrate and dissolve it in 20 ml of deionized water, and stir to obtain a silver nitrate solution; Add it dropwise to the zinc oxide dispersion under stirring conditions, and stir at a rate of 100 rpm for 8 hours to form a mixed precursor solution A; prepare 60 ml of 0.1 mol / L ammonia water, dropwise under the condition of magnetic stirring Added into mixed precursor solution A, stirred at a rate of 200 rpm for 30 minutes to obtain mixed precursor solution B, weighed 0.85 g Na 2 HPO 4 Dissolve in 20 ml of deionized water, ultrasonically dissolve to obtain a disodium hydrogen phosphate solution, add the prepared disodium hydrogen phosphate solution to the mixed precursor solution B drop by drop, the reaction system appears brownish-yellow turbid, after the dropwise addition The obtained mixed solution was continuously stirred fo...

Embodiment 2

[0032] Dissolve 150 mg of zinc oxide in 10 ml of deionized water and sonicate for 30 minutes to obtain a zinc oxide dispersion; weigh 0.51 g of silver nitrate and dissolve it in 20 ml of deionized water, and stir to obtain a silver nitrate solution; Add it dropwise to the zinc oxide dispersion under stirring conditions, and stir at a rate of 100 rpm for 6 hours to form a mixed precursor solution A; prepare 60 ml of 0.1 mol / L ammonia water, dropwise under the condition of magnetic stirring Added into mixed precursor solution A, stirred at a rate of 200 rpm for 40 minutes to obtain mixed precursor solution B; weighed 0.85 g Na 2 HPO 4 Dissolved in 20 ml of deionized water, ultrasonically dissolved to obtain a disodium hydrogen phosphate solution, and added the prepared disodium hydrogen phosphate solution dropwise to the mixed precursor solution B, and the reaction system appeared brownish-yellow turbid; The obtained mixed solution was continuously stirred for 40 minutes, and t...

Embodiment 3

[0034] Dissolve 600 mg of zinc oxide in 10 ml of deionized water and sonicate for 30 minutes to obtain a zinc oxide dispersion; weigh 0.51 g of silver nitrate and dissolve it in 20 ml of deionized water, and stir to obtain a silver nitrate solution; Add dropwise into the zinc oxide dispersion under stirring conditions, stir at 100 rpm for 10 hours to form a mixed precursor solution A, prepare 60 ml of 0.1 mol / L ammonia water, dropwise under the condition of magnetic stirring Added into mixed precursor solution A, stirred at a rate of 200 rpm for 50 minutes to obtain mixed precursor solution B, weighed 0.85 g Na 2 HPO 4 Dissolve in 20 ml of deionized water, ultrasonically dissolve to obtain a disodium hydrogen phosphate solution, add the prepared disodium hydrogen phosphate solution dropwise to the mixed precursor solution B, and the reaction system appears brownish-yellow turbid; The obtained mixed solution was continuously stirred for 50 minutes, and the obtained product was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com