High strength glass composition and fibers

A glass composition and glass fiber technology, applied in the field of fibers and their composite materials, can solve the problems of shortening the life of the fiber bushing, increasing the preparation cost, and being expensive for the fiber bushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

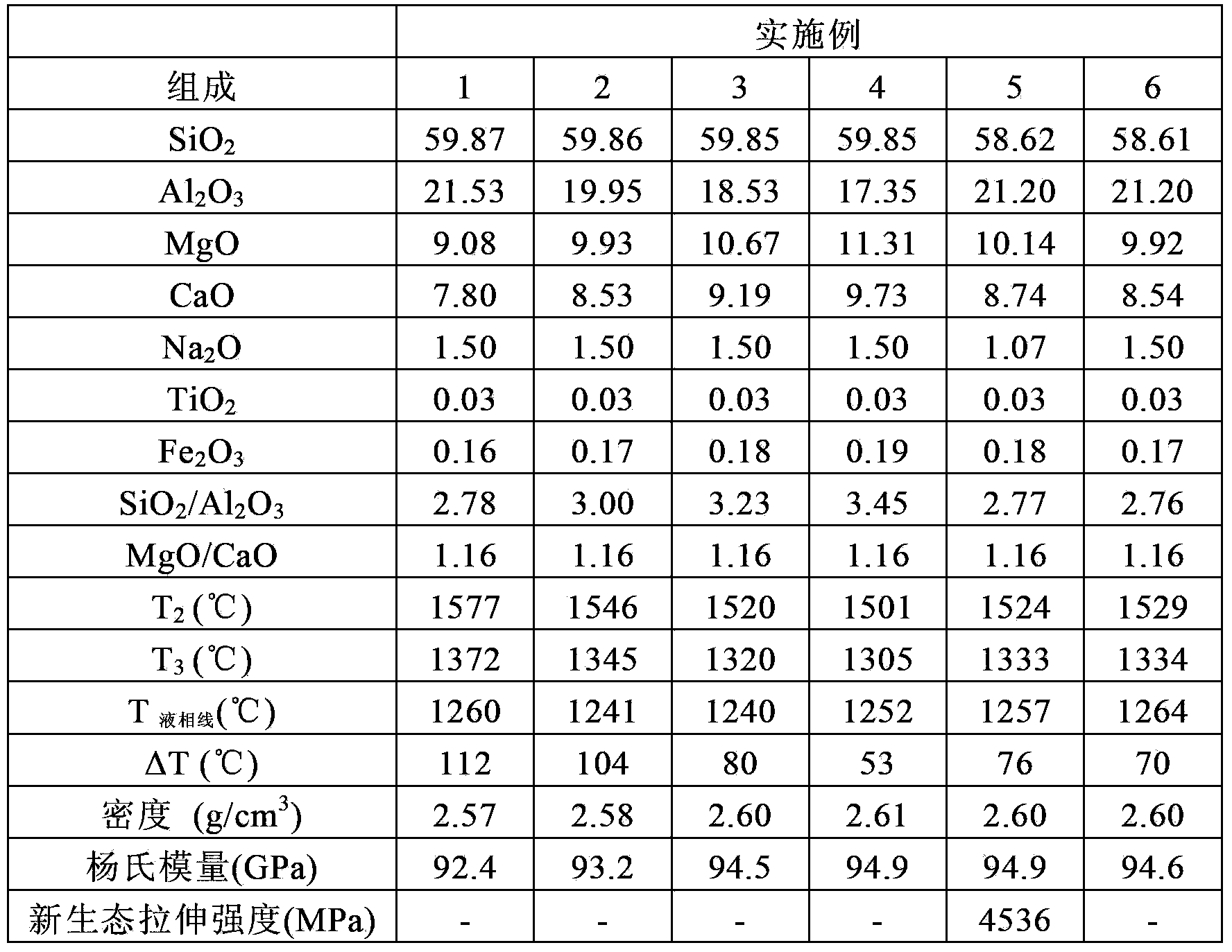

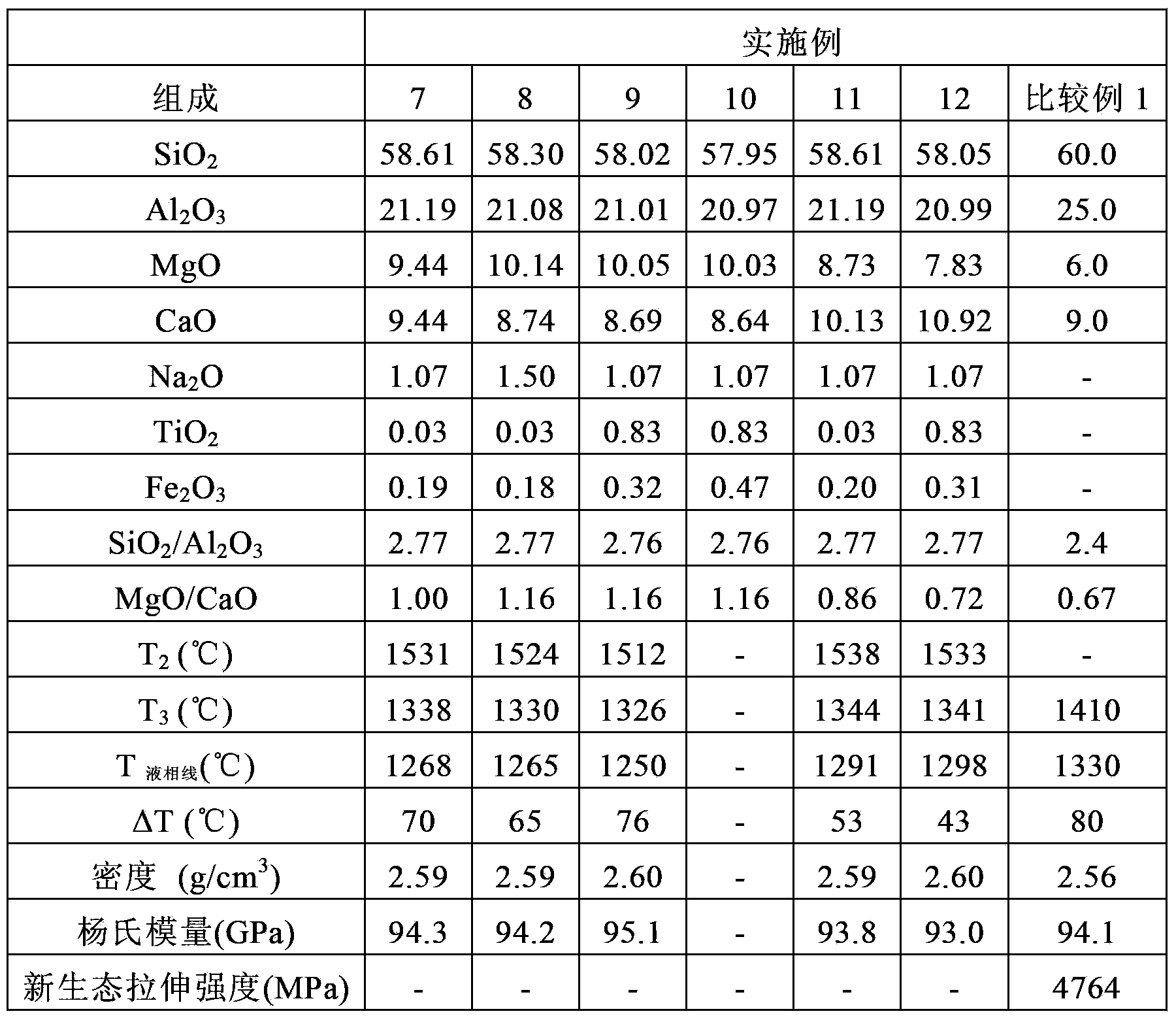

Examples

Embodiment Construction

[0011] The glasses disclosed and described herein are suitable for melting in conventional commercially available refractory lined glass melting furnaces widely used for the production of glass reinforcement fibers. By improving the mechanical properties of glass fibers, especially the Young's modulus of the fibers, the mechanical properties and effectiveness of composite parts are enhanced.

[0012] As used herein, the term "liquidus" has its conventional and common meaning and generally includes the highest temperature at which equilibrium exists between a liquid glass and its predominant crystalline phase, at all temperatures above said liquidus , the main phase of the glass melt does not contain crystals, whereas at temperatures below the liquidus, crystals can form in the melt.

[0013] As used herein, the term "delta-T (ΔT)" has its conventional and general meaning, generally including the difference between the fiberizing temperature and the liquidus, and thus relates t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com