Inversed organic thin-film solar cell and manufacturing method of inversed organic thin-film solar cell

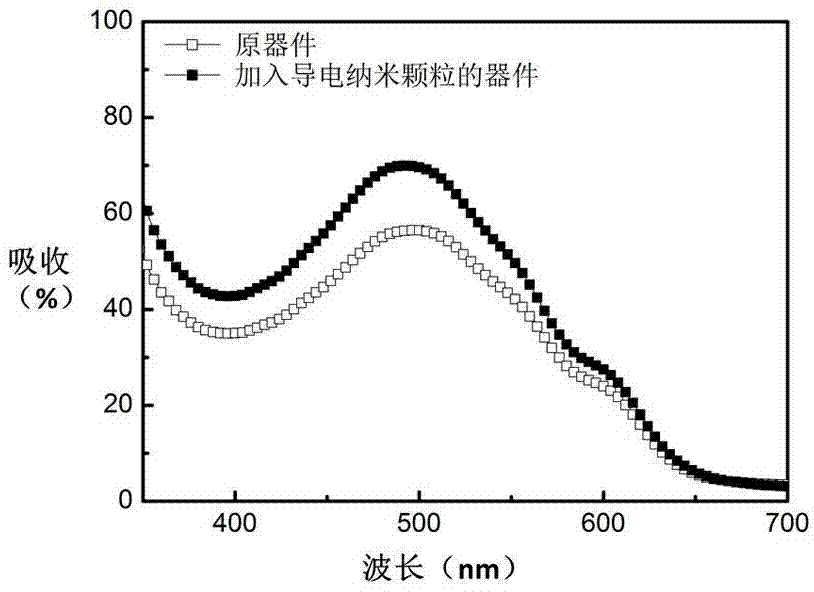

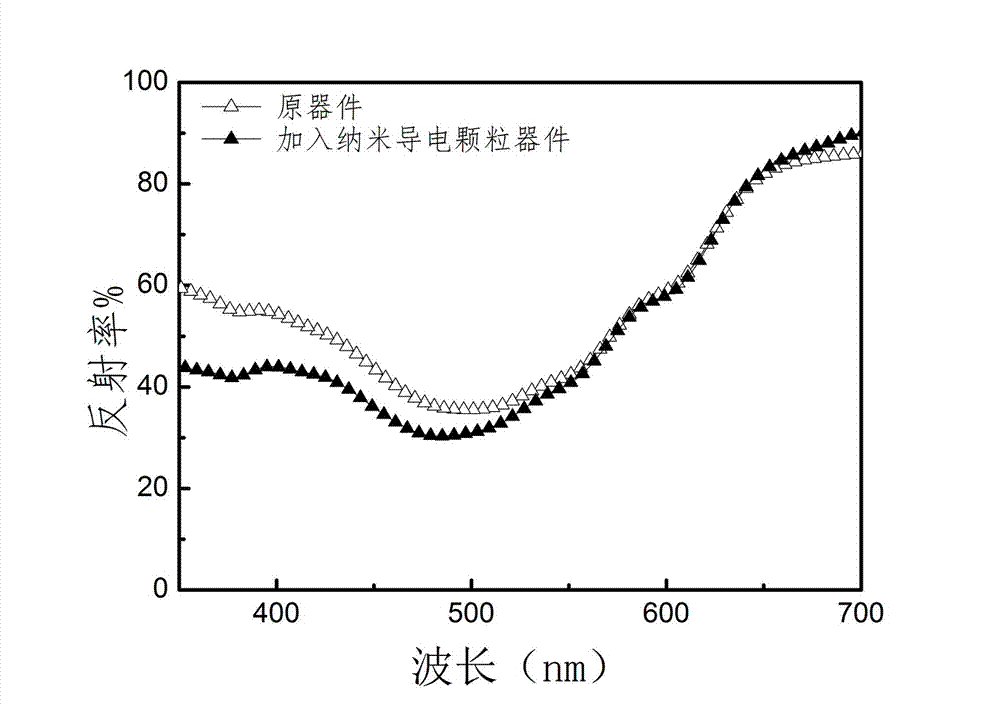

A technology of solar cells and organic thin films, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems that the thickness of the photoactive layer should not be too thick, the inability to transfer photogenerated carriers, and reduce the efficiency of carrier transfer, etc., to achieve increased The probability of light absorption and photoelectric conversion, the effect of increasing the efficiency of carrier transport and increasing the rate of electron transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: The substrate that the surface roughness is less than 1 nm is made up of transparent substrate and transparent conductive cathode ITO is cleaned, blows dry with nitrogen gas after cleaning; Spin-coat ZnO on the surface of transparent conductive cathode ITO (5000 rpm, 40 s, 15 nm), and the formed film was baked (200 ℃, 60 min); the photoactive layer of P3HT:PCBM (1:20, 20 mg / ml) was prepared by spin coating on the cathode buffer layer (1000 rpm, 25 s), and baked (140 ℃, 5 min); on the surface of the photoactive layer, spray the anode buffer layer mixed with transparent conductive nanoparticles (Ag nanoparticles, radius 30 nm, cyclohexane solvent) of PEDOT:PSS solution (transparent conductive nanoparticles 2%, dimethyl sulfoxide 5%, PEDOT:PSS 93%, 2500 rpm, 60 s, 15 nm); the substrate was annealed by heating and annealing on a constant temperature hot stage (150 ℃, 5 min); metal anode Ag (100 nm) was vapor-deposited on the anode buffer layer. Under standard...

Embodiment 2

[0033] Embodiment 2: the substrate that surface roughness is less than 1 nm is made up of transparent substrate and transparent conductive cathode ITO is cleaned, dry with nitrogen gas after cleaning; Spin-coat ZnO on the surface of transparent conductive cathode ITO (5000 rpm, 40 s, 20 nm), and the formed film was baked (200 ℃, 60 min); the photoactive layer of P3HT:PCBM (1:10, 10 mg / ml) was prepared by spin coating on the cathode buffer layer (1000 rpm, 25 s), and baked (140 ℃, 5 min); on the surface of the photoactive layer, spray the anode buffer layer doped with transparent conductive nanoparticles (Ag nanoparticles, radius 15 nm, cyclohexane solvent) of PEDOT:PSS solution (transparent conductive nanoparticles 5%, dimethyl sulfoxide 10%, PEDOT:PSS 85%, 2500 rpm, 50 s, 20 nm); the substrate was annealed by hot stage heating and annealing (170 ℃, 5 min ); the metal anode Ag (200 nm) was vapor-deposited on the anode buffer layer. Under standard test conditions: AM 1.5, 100 ...

Embodiment 3

[0034]Embodiment 3: The substrate that the surface roughness is less than 2 nm is made up of transparent substrate and transparent conductive cathode ITO is cleaned, dry with nitrogen gas after cleaning; Spin-coat ZnO on the surface of transparent conductive cathode ITO (5000 rpm, 40 s, 15 nm), and the formed film was baked (200 ℃, 60 min); the photoactive layer of P3HT:PCBM (1:10, 5 mg / ml) was prepared by spin coating on the cathode buffer layer (1000 rpm, 25 s), and baked (140 ℃, 5 min); on the surface of the photoactive layer, spray the anode buffer layer doped with transparent conductive nanoparticles (Ag nanoparticles, radius 60 nm, cyclohexane solvent) of PEDOT:PSS solution (transparent conductive nanoparticles 5%, dimethyl sulfoxide 7%, PEDOT:PSS 88%, 2500 rpm, 50 s, 20 nm); the substrate was annealed by heating and annealing on a constant temperature hot stage (150 ℃, 30 min); metal anode Ag (300 nm) was vapor-deposited on the anode buffer layer. Under standard test c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com