Microwave power probe temperature compensation device based on USB interface

A technology of temperature compensation device and USB interface, which is applied in the direction of temperature compensation modification, etc., can solve problems such as low compensation efficiency, large power value error, and poor reliability, and achieve the effects of high compensation efficiency, simple operation, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

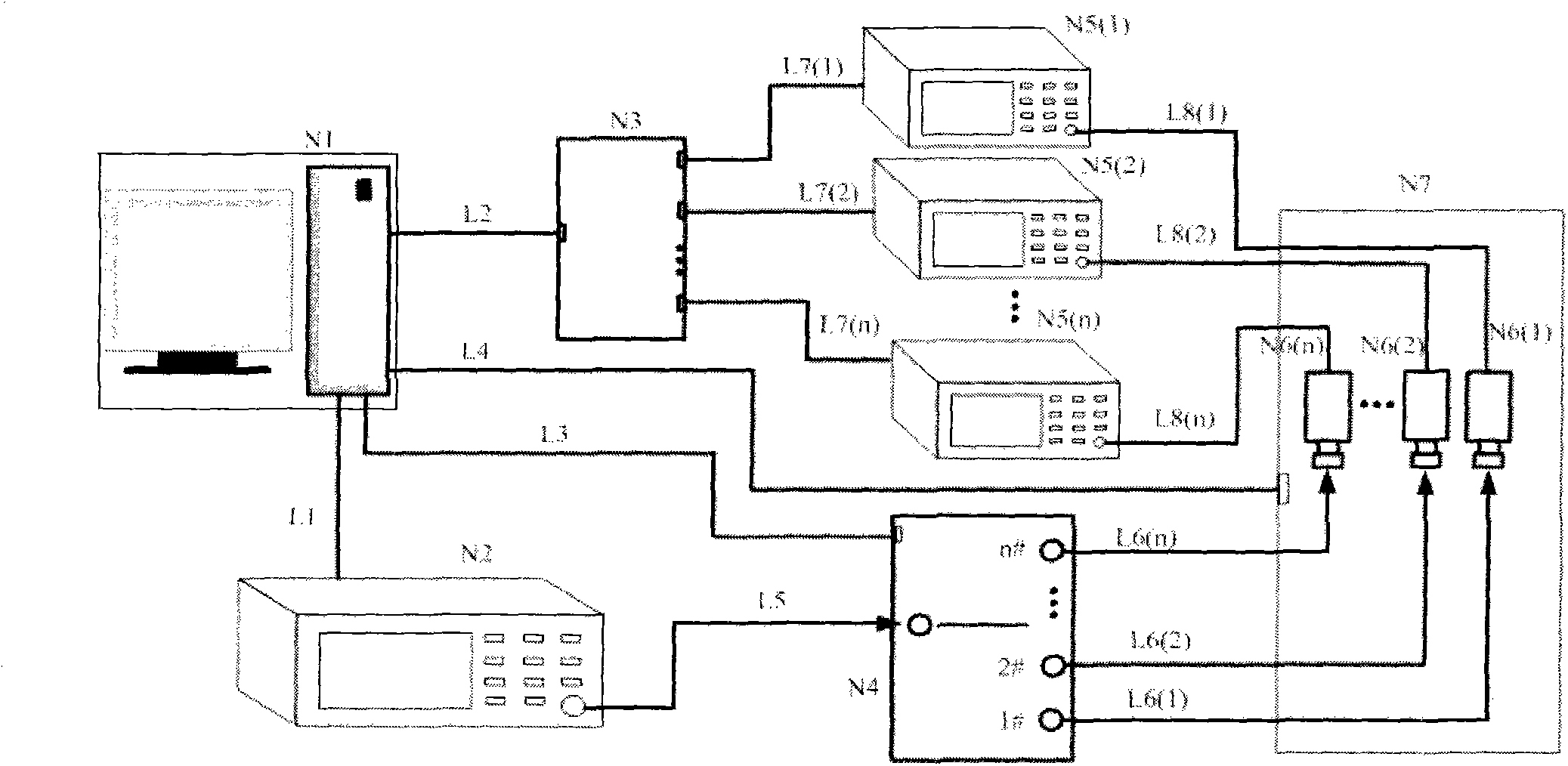

[0059] Such as figure 1Shown is a specific embodiment of the present invention, the microwave power sensor temperature compensation device based on the USB interface mainly includes a computer N1, a signal generator N2, a USB hub N3, a plurality of power meter hosts N5 and a power sensor N6, and the computer N1 has a GPIB The card is connected to the signal generator N2 through the GPIB cable L1, and the signal generator N2 is programmed to control the output power and frequency of the signal generator N2 through the GPIB command; the computer N1 is connected to the USB hub N3 through the hub USB cable L2, and the USB hub N3 Connect to multiple power meter hosts N5 through multiple USB cables L7, each power meter host N5 is connected to the corresponding power probe N6 through an independent 12-core cable L8, and the computer N1 programs multiple power meter hosts N5 through the USB hub N3 , realize the temperature compensation of the power sensor through the power meter host ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com