Bearing-reclining-type mounted assembly-type wall

A prefabricated and wall technology, applied in the direction of walls, passive houses, building components, etc., can solve the problems of large space occupation, large amount of steel bars, and impact on durability, etc., to achieve convenient construction and installation, less steel consumption, and convenient increase. thick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

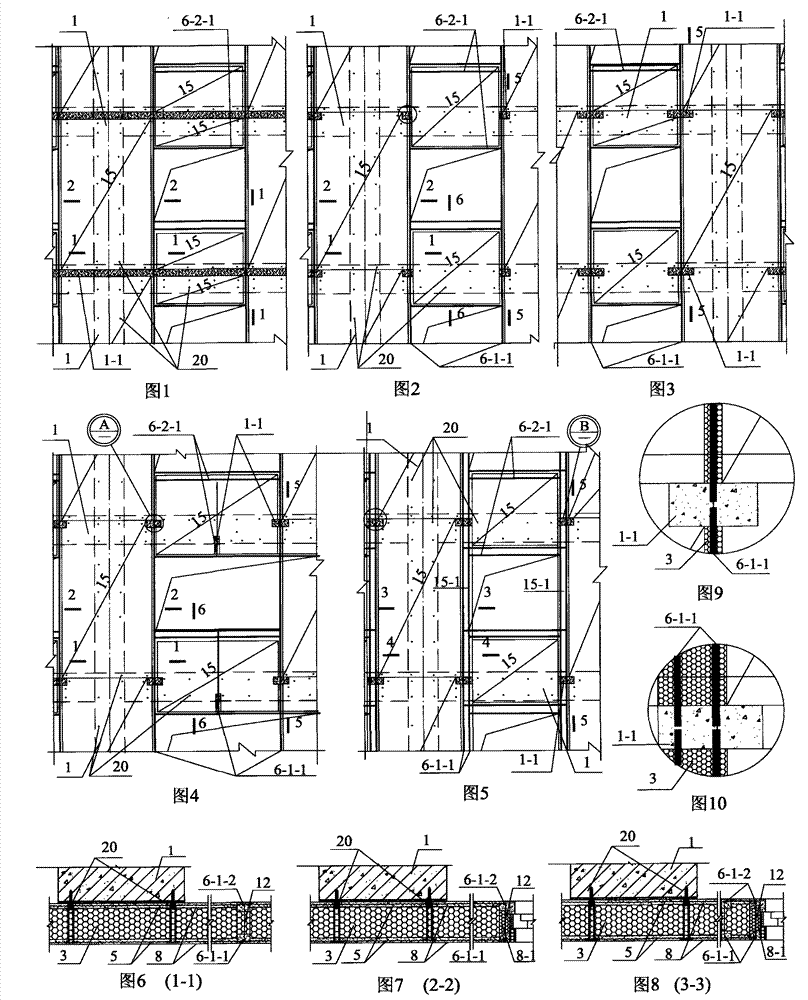

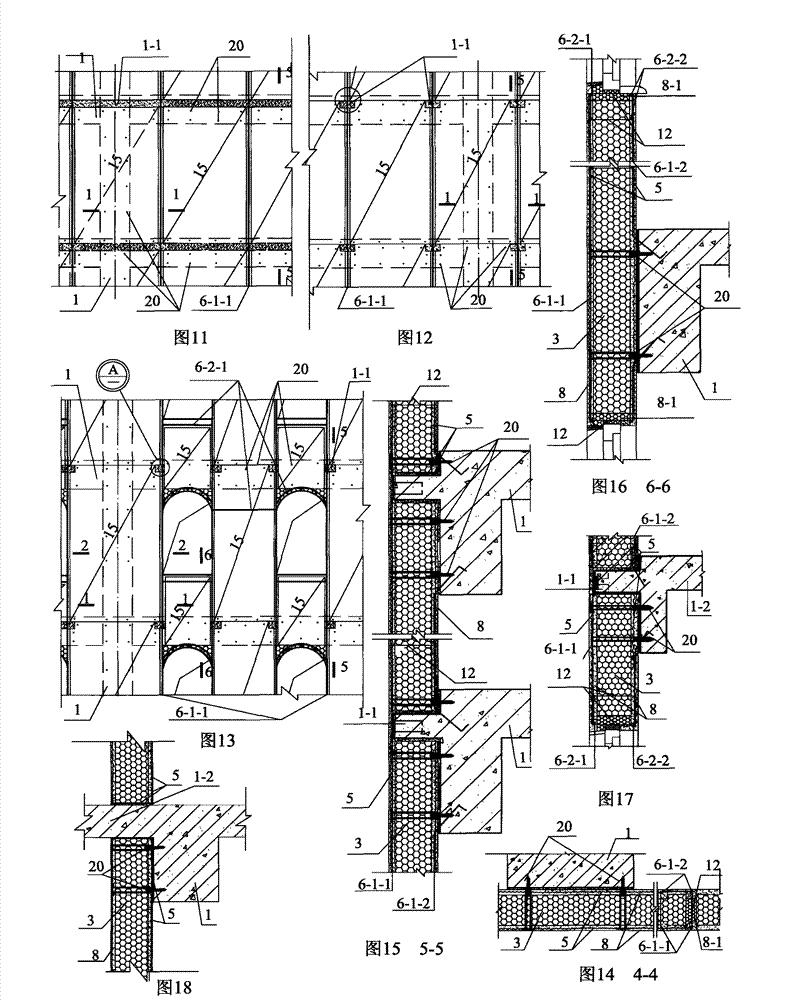

[0156] Implementation mode one: see Figure 1 to Figure 32 , Figure 41 , a prefabricated wall for supporting and leaning installation in this embodiment, which is composed of a main building structure 1, a prefabricated wall panel 15, or a prefabricated slat 15-1 (in the third embodiment, it needs to be installed Longitudinal steel bars, especially when double steel bars are installed, the double steel bars are installed on the prefabricated slats 15-1 for convenient construction); the main building structure 1 is a beam, slab, column wall and foundation, for example, the main building structure 1 is a concrete frame structure, steel concrete frame Structure, frame-shear structure, steel frame structure, steel pipe concrete structure, concrete and steel mixed frame structure, steel-wood frame structure, or bamboo frame, wood frame structure, shear wall structure, etc.;

[0157] On the outer side of the building main structure 1, there is a structural supporting part 1-1 supp...

Embodiment approach 2

[0180] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the connection between the prefabricated wall and the main building structure 1 has the following methods, choose one of them, or 1), 2), and 3) to share:

[0181] 1), use the anchor bolt 20 to fix the prefabricated wallboard 15 or the prefabricated slat 15-1 with the side of the main building structure 1 or the additional abutment part 1-3; the anchor bolt 20 penetrates the prefabricated wallboard 15, the prefabricated strip The plate 15-1 is fixed to the side of the building main structure 1 or to the additional abutting piece 1-3;

[0182] 2) Bonding the prefabricated wall panels 15 and the prefabricated slats 15-1 to the sides of the beams, slabs, columns and shear walls of the main building structure 1, or / and to the sides of the additional abutting parts 1-3 with cementing materials;

[0183] When the prefabricated wallboard 15 and the prefabricated slat 15-1 are used as the formwork of ...

Embodiment approach 3

[0190] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that this embodiment increases steel bars 6 and steel hoops 12, and the steel bars 6 are located in the prefabricated wall protection layer 8; the steel bars 6 include longitudinal steel bars 6-1 and Horizontal reinforcing bar or curved reinforcing bar 6-2, or reinforcing bar 6 is the circular reinforcing bar (not shown in drawing) that is arranged around the door and window opening; The core layer at the seam is a bare board, and the longitudinal reinforcement is installed on site. It is more convenient to install one longitudinal reinforcement because there is less wet work.), or the longitudinal reinforcement 6-1 is located in the protective layer 8 of the prefabricated slab 15-1 (that is, Formwork prefabricated prefabricated slat 15-1, because there are many wet operations during the double reinforcement, it is more convenient to install longitudinal reinforcement 6-1 in the protective laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com