Hole heat insulation break bridge structure of composite heat-preservation wall door and window

A technology for door and window openings and thermal insulation bridges, which is applied in thermal insulation, building structure, walls, etc., can solve problems such as high heat loss, large thermal bridges in openings, and unfavorable energy-saving and thermal insulation of walls, so as to reduce resistance and reduce heat loss , Improve the effect of energy-saving and thermal insulation of the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

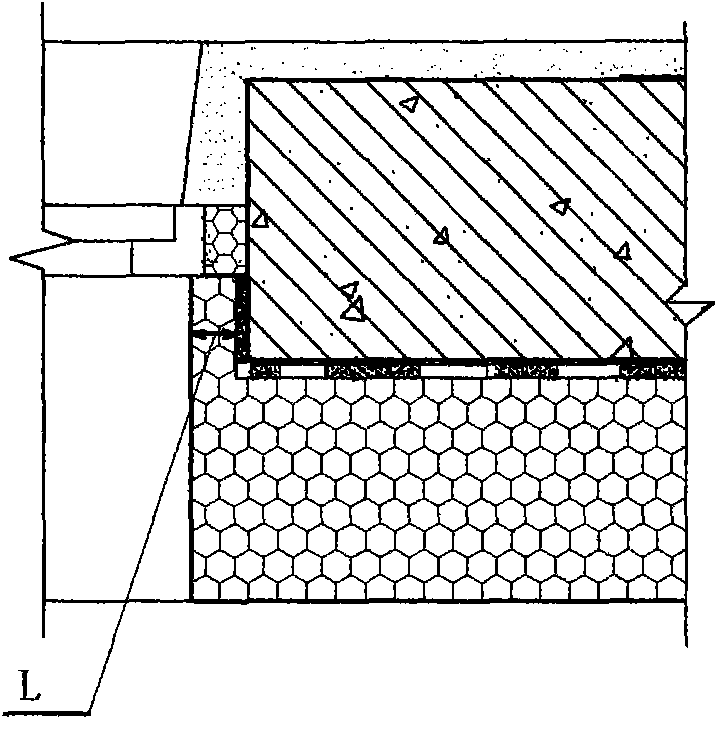

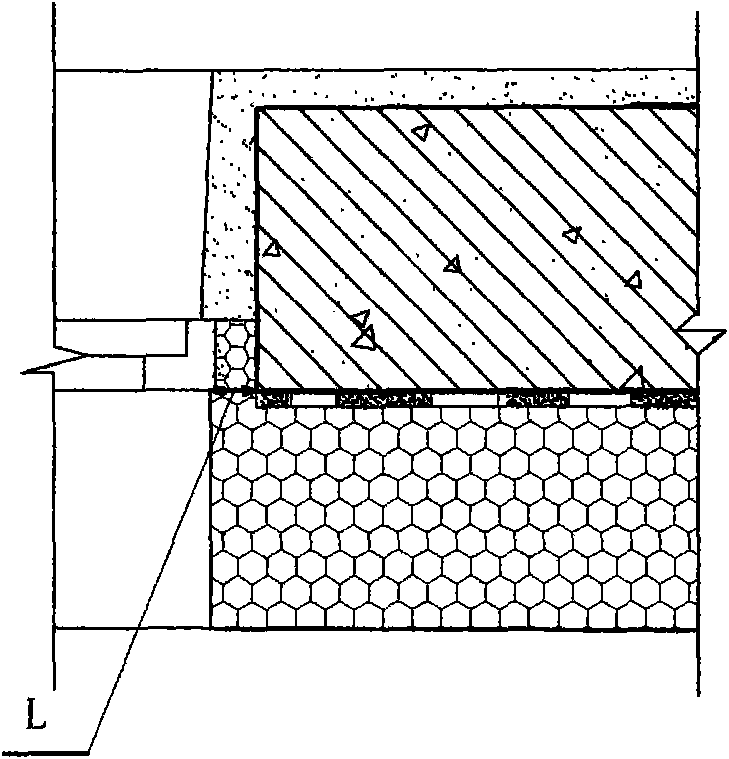

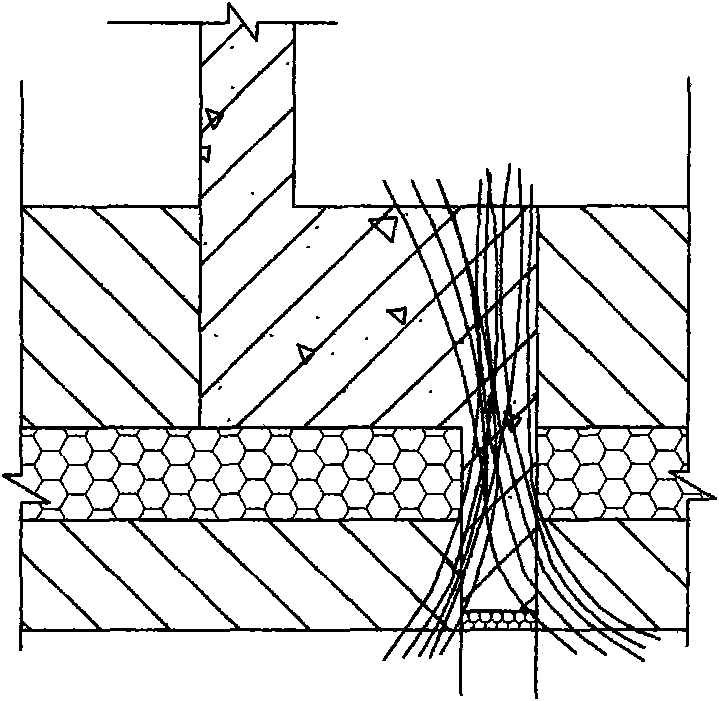

[0084] Specific implementation mode one: see Figure 4 ~ Figure 8 , a kind of thermal insulation broken bridge structure of a composite thermal insulation wall door and window opening of the present embodiment is composed of thermal insulation layer 3, indoor protective layer 8-1, outdoor protective layer 8-2, doors and windows 20; the thermal insulation layer 3 is polymer thermal insulation material or mineral wool or plant straw or paper honeycomb board or thermal insulation mortar; the indoor protective layer 8-1 and outdoor protective layer 8-2 are cement mortar or fine stone concrete plastering layer, or modified cement mortar or fine stone The concrete plastering layer, or the outdoor protective layer 8-2 located at the opening is the thermal insulation layer, or the indoor protective layer 8-1 located at the entrance is the thermal insulation mortar; the thermal insulation layer 3 is located between the indoor protective layer 8-1 and the outdoor protective layer 8 Betw...

specific Embodiment approach 2

[0088] Specific implementation mode two: see Figure 4 ~ Figure 8 , the difference between this embodiment and specific embodiment one is that this embodiment increases the alkali-resistant mesh cloth 5-1; the alkali-resistant mesh cloth 5-1 is pasted on the surface of the hole insulation layer 3, and the doors and windows 20 are installed On the alkali-resistant mesh cloth 5-1, the alkali-resistant mesh cloth 5-1 is lapped and pasted with the indoor protective layer 8-1 and the outdoor protective layer 8-2.

[0089]Alkali-resistant mesh is the abbreviation for alkali-resistant glass fiber mesh in the JCT-841-2007 standard of "Alkali-resistant Glass Fiber Mesh". The strength retention rate of alkali-resistant mesh in strong alkali ordinary Portland cement can not be less than 80%, and the alkali-resistant mesh has considerable tensile capacity. The GRC wallboard added with alkali-resistant chopped glass fiber has been used abroad since the 1970s. At present, there are enginee...

specific Embodiment approach 3

[0090] Specific implementation mode three: see Figure 4 ~ Figure 8 , The difference between this embodiment and Embodiment 1 or 2 is that this embodiment adds a waterproof and moisture-proof layer 15, and the waterproof and moisture-proof layer 15 is a polymer waterproof coiled material or a plastic film or a plastic composite film; the waterproof and moisture-proof layer 15 has the following installation methods: a, waterproof and moisture-proof layer 15 replaces alkali-resistant mesh cloth 5-1, and is directly pasted on the surface of the hole insulation layer 3, and doors and windows 20 are installed on the hole waterproof and moisture-proof layer 15; b, waterproof and moisture-proof layer 15 is pasted on Above the alkali-resistant mesh cloth 5-1 of the hole, the doors and windows 20 are installed on the waterproof and moisture-proof layer 15 of the hole; c, the waterproof and moisture-proof layer 15 is pasted on the surface of the hole insulation layer 3, and the alkali-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com