A kind of uv anti-scratch matte clear topcoat

A topcoat and polyurethane acrylate technology, which is applied in the coating field in the chemical industry, can solve the problems of prolonged working hours, air pollution by organic solvents, and increased processes, and achieve improved production efficiency, excellent hardness and scratch resistance, and good leveling properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

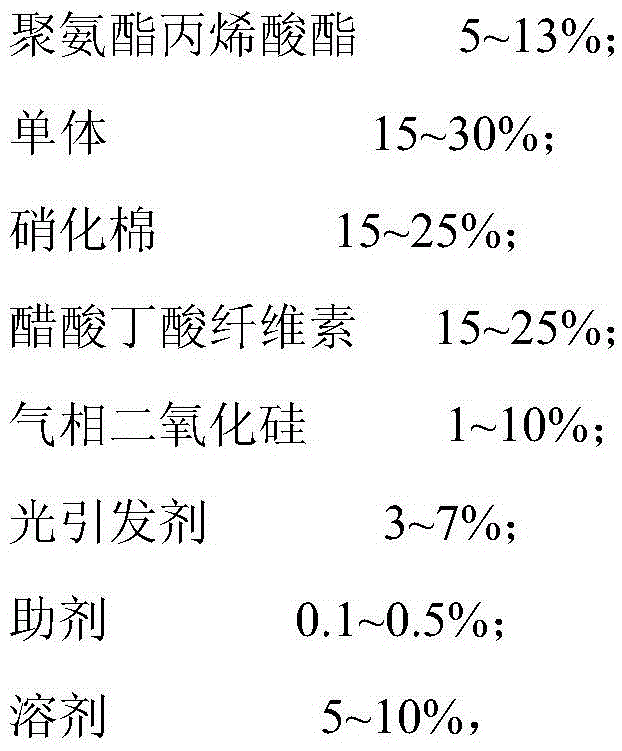

Method used

Image

Examples

Embodiment 1

[0040] A kind of UV anti-scratch matt clear finish paint, by weight percentage: YTM63185%, YTM56075%, tripropylene glycol diacrylate 5%, trimethylolpropane triacrylate 6%, 1,6-hexanediol Diacrylate 6%, Ethoxylated Trimethylolpropane Triacrylate 7%, Nitrocellulose 23%, Cellulose Acetate Butyrate 23%, Fumed Silica 8%, 1-Hydroxy-Cyclohexyl-Benzene Methyl ketone 2%, 2-hydroxy-2-methyl-1-phenyl-1-propanone 2%, (2,4,6-trimethylbenzoyl) diphenylphosphine oxide 2%, butyl acetate 1% ester, 1% ethanol, 2% ethyl acetate, 1.7% isopropanol, BYK1410.1%, DEGO4500.2%. According to the paint making method commonly used by those skilled in the art, the above materials are made into UV matte clear topcoat, and the equipment is automatically sprayed on the substrate, which can greatly improve the production efficiency. Excellent leveling property can be obtained after curing, which can achieve the surface effect of PU paint, and its hardness and scratch resistance are better than PU paint.

Embodiment 2

[0042] A kind of UV anti-scratch matte varnish, by weight percentage: YTM63182%, YTM56073%, tripropylene glycol diacrylate 6%, trimethylolpropane triacrylate 7%, 1,6-hexanediol Diacrylate 6%, Ethoxylated Trimethylolpropane Triacrylate 8%, Nitrocellulose 23%, Cellulose Acetate Butyrate 23%, Fumed Silica 7%, 1-Hydroxy-Cyclohexyl-Benzene Methyl ketone 3%, 2-hydroxy-2-methyl-1-phenyl-1-propanone 2%, (2,4,6-trimethylbenzoyl) diphenylphosphine oxide 1%, butyl acetate Ester 1.7%, ethanol 2%, ethyl acetate 2%, isopropanol 3%, BYK1410.1%, BYK-3330.2%. According to the paint making method commonly used by those skilled in the art, the above materials are made into UV matte clear topcoat, and the equipment is automatically sprayed on the substrate, which can greatly improve the production efficiency. Excellent leveling property can be obtained after curing, which can achieve the surface effect of PU paint, and its hardness and scratch resistance are better than PU paint.

Embodiment 3

[0044] A kind of UV anti-scratch matte clear topcoat, by weight percentage: YTM56074%, YTM63184%, tripropylene glycol diacrylate 7%, trimethylolpropane triacrylate 4%, 1,6-hexanediol Diacrylate 5%, Ethoxylated Trimethylolpropane Triacrylate 8%, Nitrocellulose 23%, Cellulose Acetate Butyrate 21%, Fumed Silica 9%, 1-Hydroxy-Cyclohexyl-Benzene Methyl ketone 2%, 2-hydroxy-2-methyl-1-phenyl-1-propanone 2%, (2,4,6-trimethylbenzoyl) diphenylphosphine oxide 2%, ethanol 2.8 %, ethyl acetate 4%, isopropanol 2%, BYK1410.1%, DEGO4500.1%. According to the paint making method commonly used by those skilled in the art, the above materials are made into UV matte clear topcoat, and the equipment is automatically sprayed on the substrate, which can greatly improve the production efficiency. Excellent leveling property can be obtained after curing, which can achieve the surface effect of PU paint, and its hardness and scratch resistance are better than PU paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com