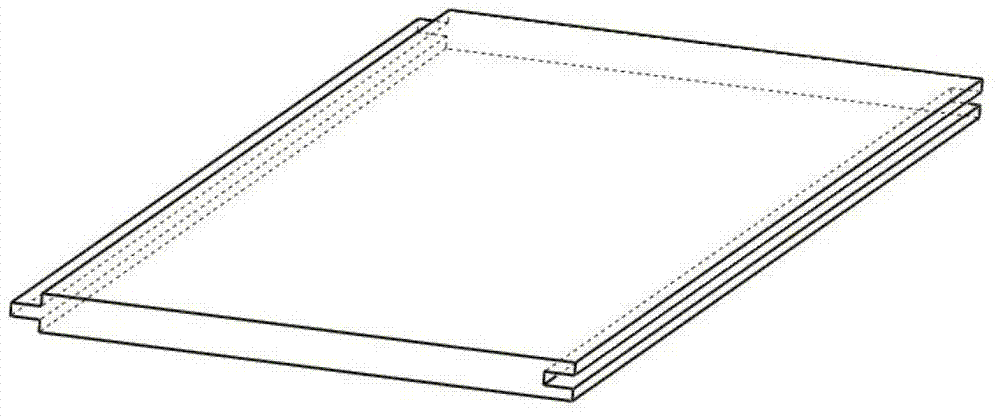

High-transverse-strength pultrusion structural sheet material and manufacturing method thereof

A technology of structural plates and manufacturing methods, which is applied in the field preparation of building components, building structures, formwork/formwork components, etc., can solve the problems of uneven cement surface, easy corrosion of steel, and collision deformation of steel formwork, etc., to achieve Convenient secondary processing, high longitudinal strength, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

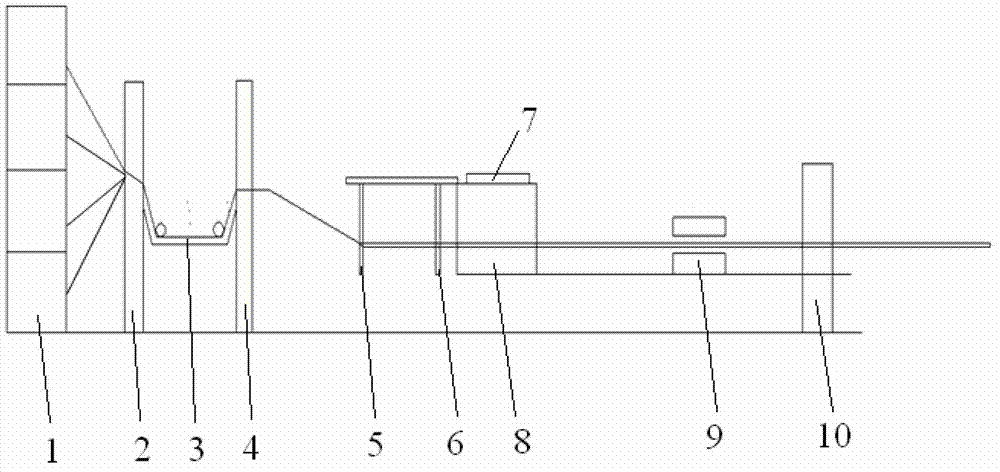

Method used

Image

Examples

Embodiment 1

[0048] The process of making a structural plate with a width of 900 mm and a thickness of 5 mm with an alkali-free glass fiber roving reinforced unsaturated polyester resin system further illustrates the present invention. The resin system formula and reinforcing material details are shown in the following table:

[0049] Table 1 Resin system formula and detailed information

[0050]

[0051] Table 2 Reinforcement material details

[0052]

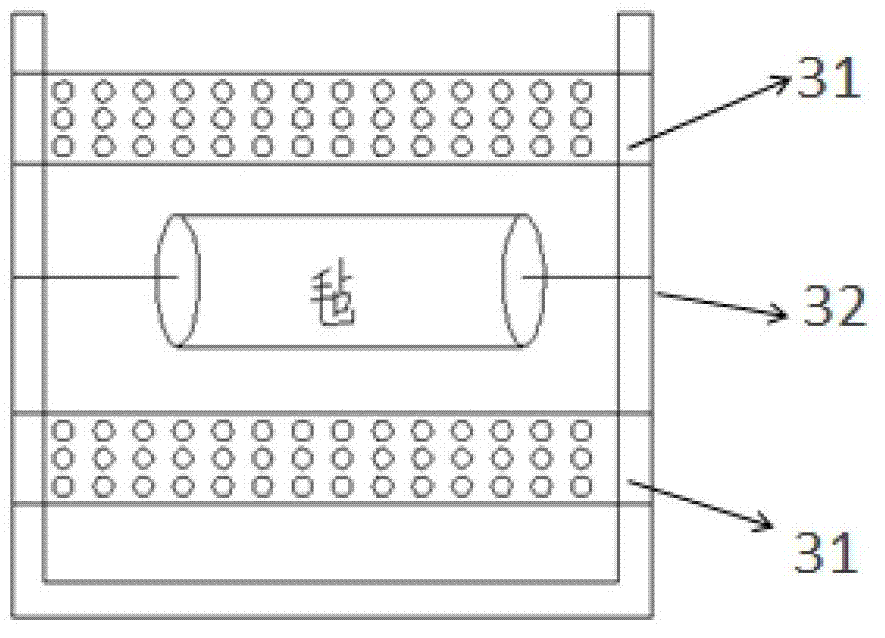

[0053] Remarks: The higher the mass fraction of the reinforcing material, the higher the mechanical properties of the product. Generally, the mass fraction of reinforcing materials in composite products produced by pultrusion is 50-70%. In this embodiment, a product with a mass fraction of 60% of the reinforcing material is obtained, and at the same time, the product has a relatively high transverse strength. The reinforcing material is composed of two layers of composite felt and one layer of woven felt, wherein the composite felt ...

Embodiment 2

[0063] The process of making a structural plate with a width of 600 mm and a thickness of 1.6 mm with an alkali-free glass fiber roving reinforced vinyl resin system further illustrates the present invention. In the resin system formula, the resin type is changed to vinyl resin, and the rest are the same as in Example 1. The details of the reinforcement materials are listed in Table 3.

[0064] Table 3 Reinforcement material details

[0065]

[0066] Remarks: In this example, a product with a mass fraction of 60% of the reinforcing material is prepared, and at the same time the product has a relatively high transverse strength. The reinforcing material is composed of two layers of composite felt, one layer of composite felt on the upper and lower surfaces of the product, and the others 2400tex non-alkali glass fiber roving, the estimation method of non-alkali glass fiber roving is as follows: product mass per meter ω=ρV, according to experience product density is 1.8g / cm 3...

Embodiment 3

[0074] The process of making a structural plate with a width of 600 mm and a thickness of 1.6 mm with an alkali-free glass fiber roving reinforced phenolic resin system further illustrates the present invention. The resin system formula and detailed information are shown in Table 4. The detailed information of the reinforcing material is the same as Table 3 in Example 2.

[0075] Table 4 Resin system formula and detailed information

[0076]

[0077] Specific steps are as follows:

[0078] (1) Production preparation: First, the lower layer of composite felt passes through the yarn guide frame, preformed mold, and mold in turn, and after being pulled out to a certain length, the upper layer of composite felt is cut into sharp corners and stitched smoothly to the passed composite felt with a needle thread , under the traction of the composite felt, the upper composite felt passes through the mold. The two-layer felt is pulled out of the mold for a certain distance and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com