Super-large-span all-glass-fiber-reinforced-plastic deodorization cover plate and odor collection device

A fiberglass and smelly cover technology, which is applied in the direction of smoke removal, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of airflow obstruction, joint seal damage, easy accumulation of rain and snow, etc. The effect of strengthening the longitudinal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

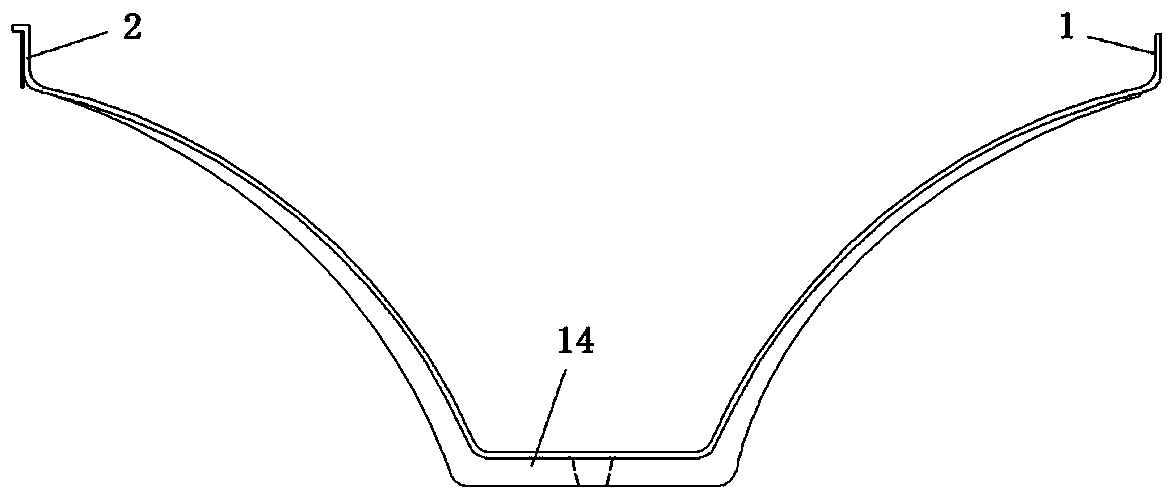

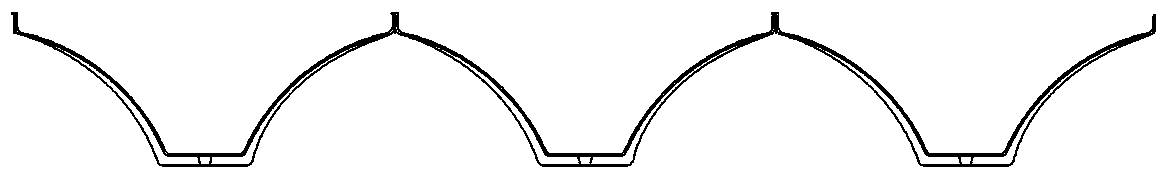

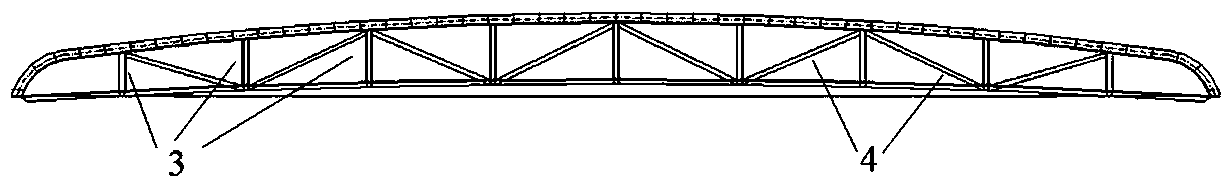

[0039] like Figure 1-3 As shown, the deodorizing cover plate of the present invention is made of high-strength glass fiber reinforced plastics without metal skeleton support. The cross section of the cover plate is a large-span arch, and the longitudinal section is a continuous small-span arch. It is formed by connecting several cover plate units, and its characteristic is that the connection of the cover plate units is located at the top of each small-span arch, and the cover plate units are connected by flanges, and the cover plate units are connected between the two half-arches. There is an integrally formed walkway 14 between the side wings of the cover plate unit. The inner wall of the side wing of the cover plate unit is provided with reinforcing ribs made of glass fiber reinforced plastics. The reinforcin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com