Laser cutting machine for cutting glass LED lampshade

A technology of LED glass and laser cutting machine, which is applied in the direction of glass production, glass manufacturing equipment, glass cutting device, etc., can solve the problems of low safety, heavy pollution, manpower and time loss, etc., so as to reduce labor intensity and production cost , Good consistency of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

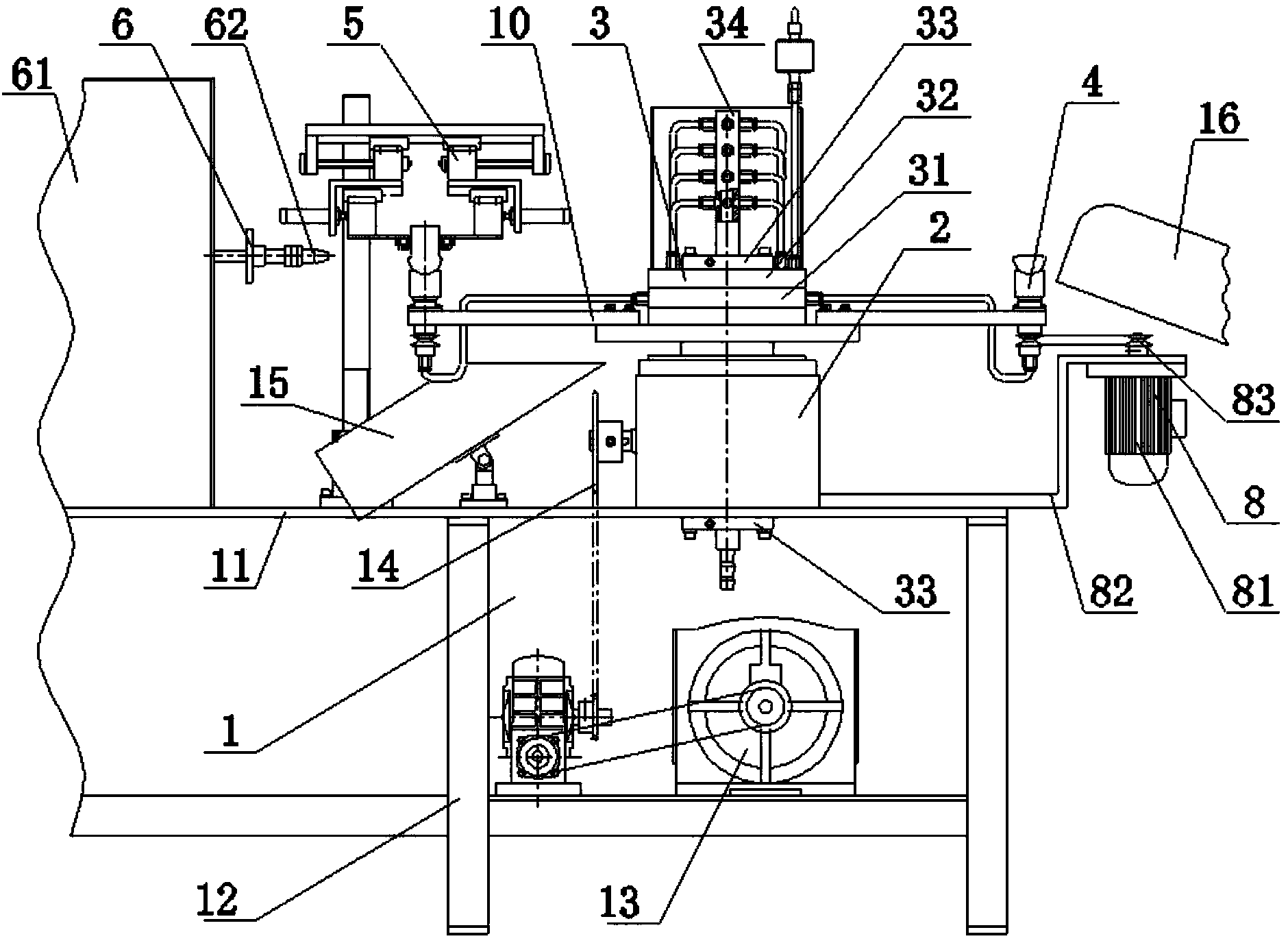

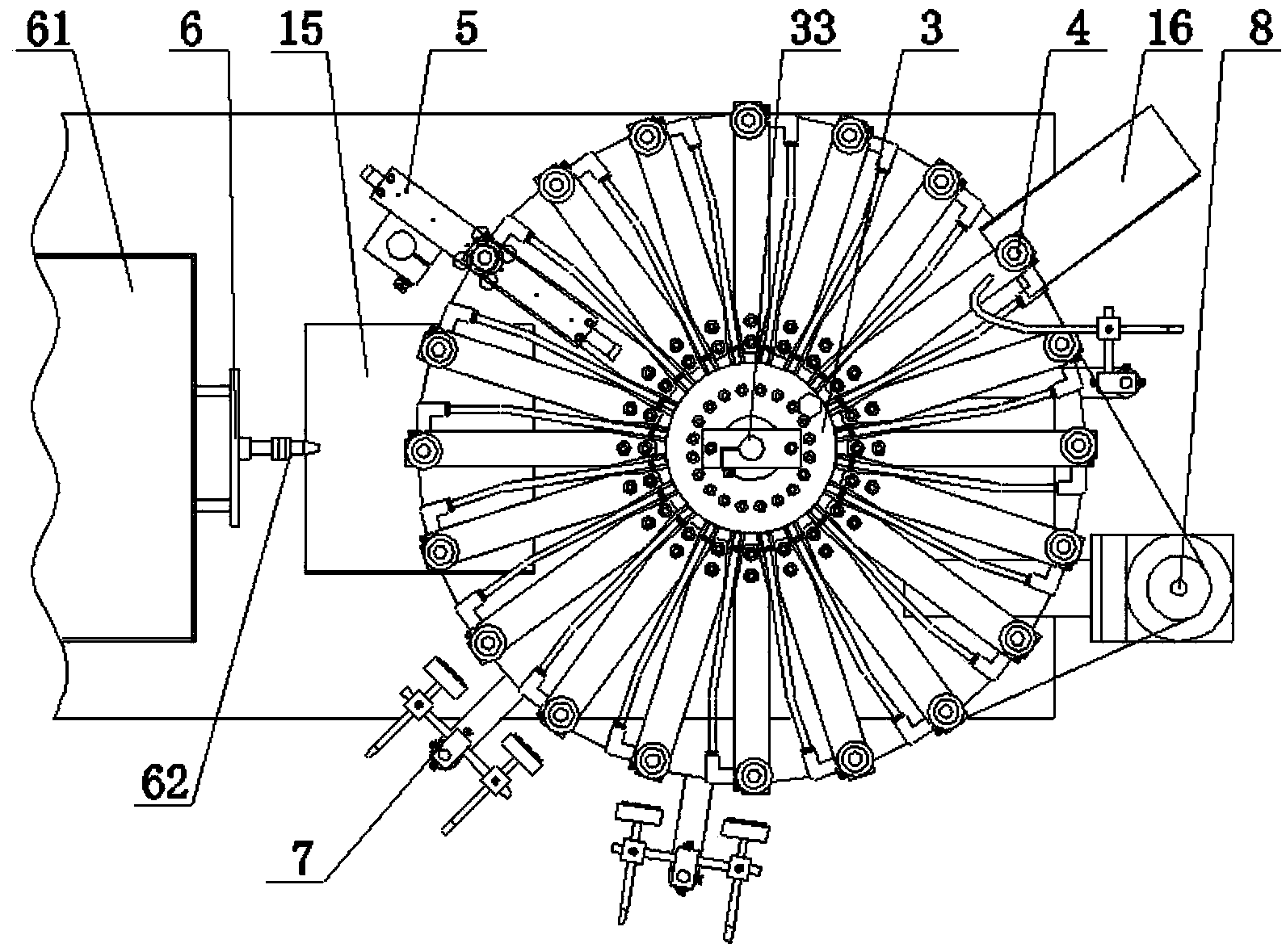

[0019] refer to figure 1 , figure 2 As shown, a laser cutting machine for cutting LED glass lampshades of the present invention includes a body 1 composed of a table 11 and a frame 12, a transmission device 13, a cam divider 2 and a station turntable 10, and the transmission device 13 is set In the lower part of the frame 12, the cam divider 2 installed on the table 11 is driven to rotate through the sprocket transmission pair 14, and the intermittent transmission of the station turntable 10 is realized. The station turntable 10 is installed on the cam divider 2, and the station turntable 10 is provided with a vacuum system 3, and twenty station fixtures 4 are evenly fixed and distributed in the circumferential direction on the upper surface of the station turntable 10, and a glass bulb rectifying device 5 and a laser cutting device 6 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com