Integrated processing device of aquatic product unfreezing wastewater and application thereof

A technology for aquatic products and wastewater, applied in the field of thawing wastewater treatment, integrated wastewater treatment devices, and integrated treatment of aquatic product thawing wastewater devices, can solve the problems of high cod and high salinity of saline wastewater, and achieve the Small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

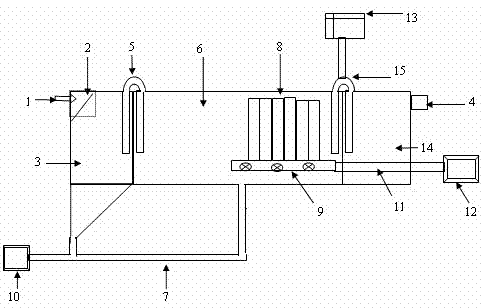

[0011] see figure 1 , an integrated device for treating thawed wastewater from aquatic products, consisting of a water inlet 1, a grille 2, a sedimentation tank 3, a water outlet 4, a pipeline 5, a sewage tank 6, a sludge pipeline 7, a membrane device 8, and a micro-aeration device 9. Composed of a sludge pump 10, an aeration pipeline 11, an aeration pump 12, a water pump 13, an outlet pool 14, and a second pipeline 15. The water inlet 1 is located above the sedimentation tank 3, the grille 2 is located behind the water inlet 1, the sedimentation tank 3 is connected to the sewage tank 6 through the first pipeline 5, the bottom of the sedimentation tank 3 is a triangular design, and the sewage tank 6 is equipped with a membrane device 8 , the bottom of the membrane device 8 is provided with a micro-aeration device 9, the membrane device 8 is connected to the water pump 13 through the second pipeline 15, the water pump 13 is connected to the second pipeline 15, and the second pi...

Embodiment 2

[0014] An aquatic product enterprise in the coastal area of the East China Sea uses 150 tons of seawater per day. After a large amount of seawater is used for thawing, the waste water produced is difficult to pass. The thawed water is applied to the device of the present invention (see figure 1 ), the flow size is 15 tons per hour, wherein the sedimentation tank 3 has a volume of 50 cubic meters, the sewage tank 6 is 200 cubic meters, and the outlet pool 14 has a volume of 50 cubic meters. The molecular weight cut-off of the membrane is 30,000 Daltons. After operation, the chroma and suspended solids of the effluent all meet the national discharge requirements, and the COD removal rate is over 50%. See Table 1 for the results.

[0015]

Embodiment 3

[0017] An aquatic product enterprise in the coastal area of the East China Sea uses 100 tons of seawater per day. After a large amount of seawater is used for thawing, the waste water produced is difficult to pass. The water quality of former thawed water is referring to Table 2, and this thawed water is applied to the device of the present invention to process (see figure 1 ), the flow rate is 15 tons per hour, among which the sedimentation tank 3 has a volume of 30 cubic meters, the sewage tank 6 has a volume of 150 cubic meters, and the outlet pool 14 has a volume of 30 cubic meters. The membrane molecular weight cut-off of the membrane equipment is 3,000 Daltons, and the COD, chroma, and suspended solids of the effluent after the operation of the device all meet the national secondary standard for sewage discharge. See Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com