Graphene fiber with multilevel pore structure, and preparation method and application thereof

A graphene fiber, multi-level hole technology, applied in graphene, other chemical processes, hybrid capacitor electrodes, etc., can solve problems such as unfavorable electrochemical energy storage device performance improvement, reduction of electrode material device ratio, and poor processing performance. , to achieve the effect of reduced production cost, easy film processing, and increased capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

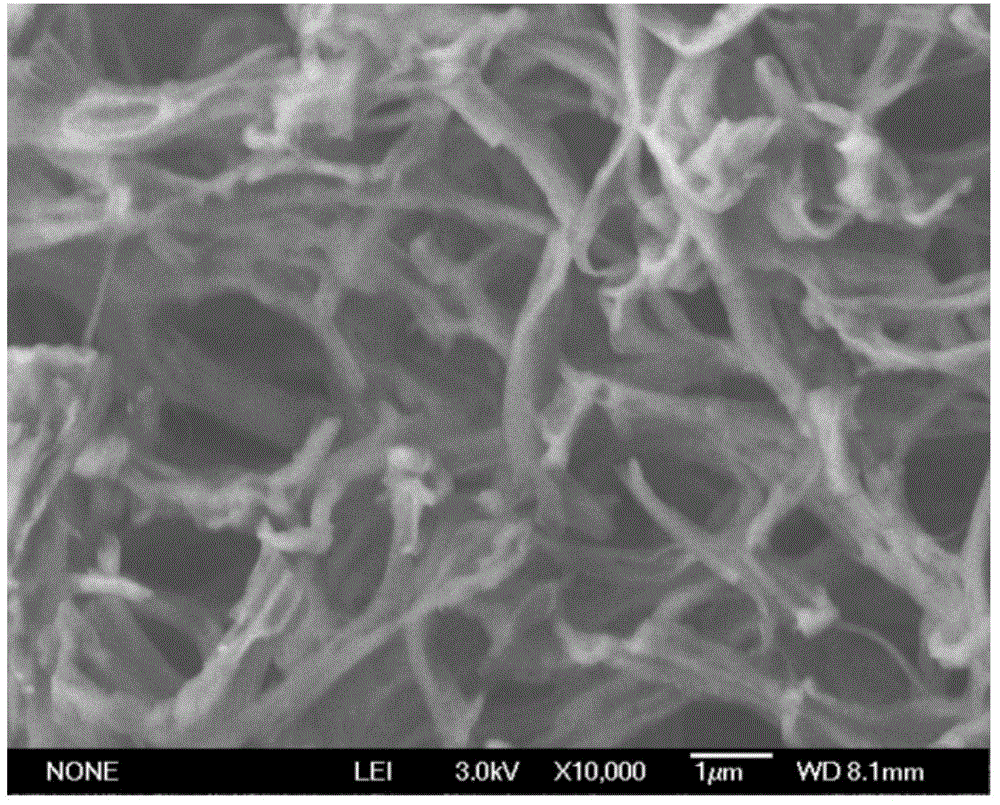

Embodiment 1

[0025] Hydrated magnesium carbonate is used as the inorganic template, with a diameter of 0.01 μm and an aspect ratio of 1000:1. Put it in a fixed bed, raise the temperature to 500°C under the atmosphere of argon as the carrier, and then pass the process gas (a mixture of hydrogen, propane and argon, the volume ratio is 1:1:5) at the same temperature break down. Carbon is deposited on the inorganic fiber template to obtain a composite of carbon and inorganic fibers. After reacting for 0.01 hour, the process gas was turned off. Cool down to room temperature in hydrogen and argon (volume ratio 1:4). The solid product was taken out and treated with 0.5 mol / L hydrochloric acid at 90°C for 0.1 hour. Filtered, washed with deionized water until neutral, and dried to obtain the final product. The product is a graphene fiber with a hierarchical porous structure, with an outer diameter of 0.01 μm, an aspect ratio of 1000:1, and a specific surface area of 2800 m 2 / g, in the form ...

Embodiment 2

[0028] Magnesium sulfate hydrate is used as the inorganic template, with a diameter of 1 μm and an aspect ratio of 800:1. Put it in a fluidized bed, raise the temperature to 700 ° C under the atmosphere of nitrogen as the carrier, and then pass the process gas (hydrogen, a mixture of ethane, ethylene and argon, the composition ratio is 5:0.7:0.3:5 ) decompose at the same temperature. Carbon is deposited on the inorganic fiber template. A composite of carbon and inorganic fibers is obtained. After reacting for 0.1 hour, the process gas was turned off. Cool down to room temperature in hydrogen and nitrogen (volume ratio 1:2). The solid product was taken out and treated with 0.1 mol / L hydrochloric acid at 5°C for 4 hours. Filtered, washed with deionized water until neutral, and dried to obtain the final product. The product is a graphene fiber with a hierarchical porous structure, with an outer diameter of 1 μm, an aspect ratio of 800:1, and a specific surface area of 1500...

Embodiment 3

[0031] Magnesium oxide is used as an inorganic template with a diameter of 100 μm and an aspect ratio of 20:1. Put it in a moving bed, heat it up to 1200°C under the atmosphere of hydrogen as the carrier, and then pass the process gas (a mixture of hydrogen, methane, butanol and argon, the composition ratio is 1:4.9:0.1:5) in the Decompose at the same temperature. Carbon is deposited on the inorganic fiber template to obtain a composite of carbon and inorganic fiber. React for 2 hours, turn off the process gas. Cool down to room temperature in hydrogen and argon (volume ratio 3:4). The solid product was taken out and treated with 0.1 mol / L nitric acid at 5°C for 2 hours. Filtered, washed with deionized water until neutral, and dried to obtain the final product. The product is a graphene fiber with a hierarchical porous structure, with an outer diameter of 100 μm, an aspect ratio of 20:1, and a specific surface area of 500 m 2 / g.

[0032] A supercapacitor at 4V (with E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com