Thermo-sensitive non-grain plate, manufacturing method for thermo-sensitive non-grain plate and application of thermo-sensitive non-grain plate

A non-gritty, heat-sensitive technology, applied in printing plate preparation, printing surface preparation, printing plate, etc., can solve the problems of environmental pollution, plate cost increase, etc., to protect the environment, save power consumption, and meet the requirements of absorption Ink and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

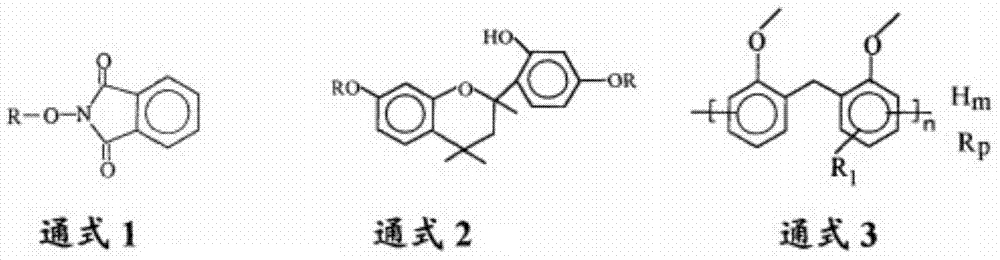

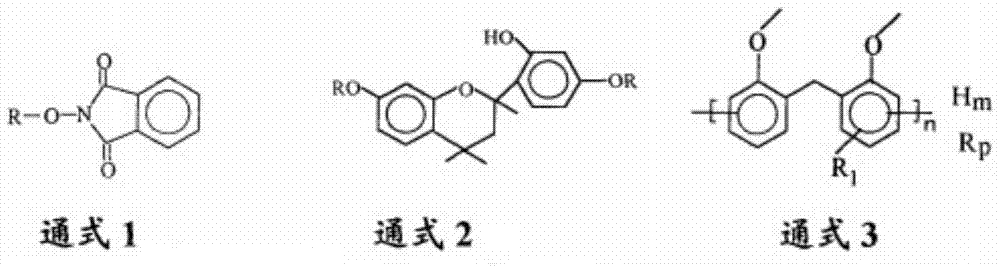

Method used

Image

Examples

Embodiment 1

[0028] Zinc oxide with a particle size of 3000nm is evenly sprayed on an aluminum plate, and then a layer of thermal imaging composition is coated on the aluminum plate by a spin coating method, and dried to obtain a thermal non-gritty printing plate.

[0029] The thermal imaging composition is composed of 10g of 1-methoxyphenyl-3,5-bistrichloromethyl triazine, 80g of phenol-formaldehyde resin, 5g of methoxymethylated melamine, and 5g of molybdenum Cyan dye, composed of 0.5g of basic brilliant blue, finally added 500g of solvent cyclohexanone and mixed evenly.

Embodiment 2

[0031] Alumina with a particle size of 3000nm is uniformly dispersed in phenolic resin, and then coated on a copper plate, the mass ratio of alumina and phenolic resin is 1:10; finally, a layer of thermal imaging composition is coated on it by spin coating , drying, that is, a heat-sensitive non-gritty printing plate.

[0032] The thermal imaging composition is composed of 15g of 1-p-methoxystyryl-3,5-bistrichloromethyl triazine, 50g of poly-p-hydroxystyrene, 10g of methoxymethylated phenol resin, 3g of merocyanine dye, 1g of basic brilliant blue, and finally add 500g of solvent dichloromethane and mix evenly.

Embodiment 3

[0034] Evenly disperse zinc oxide with a particle size of 200nm in acrylic resin, and then coat it on an aluminum plate. The mass ratio of zinc oxide and acrylic resin is 1:6; finally, coat a thermal imaging layer on it by spin coating method. The composition is dried to obtain a heat-sensitive non-gritty printing plate.

[0035] The thermal imaging composition is composed of 20g of 1-p-methoxystyryl-3,5-bistrichloromethyl triazine, 70g of phenol-o-cresol-formaldehyde resin, and 5g of methoxymethylated Melamine, 5g of methoxymethylated phenol resin, 5g of merocyanine dye, 1g of malachite green, and finally add 500g of solvent methyl ethyl ketone and mix evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com