A method for milling and slotting an open blisk

An integral blisk and groove processing technology, applied in metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve the problems of large material removal, easy tool wear, low processing efficiency, etc., to improve forming quality and processing time. , the effect of improving the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

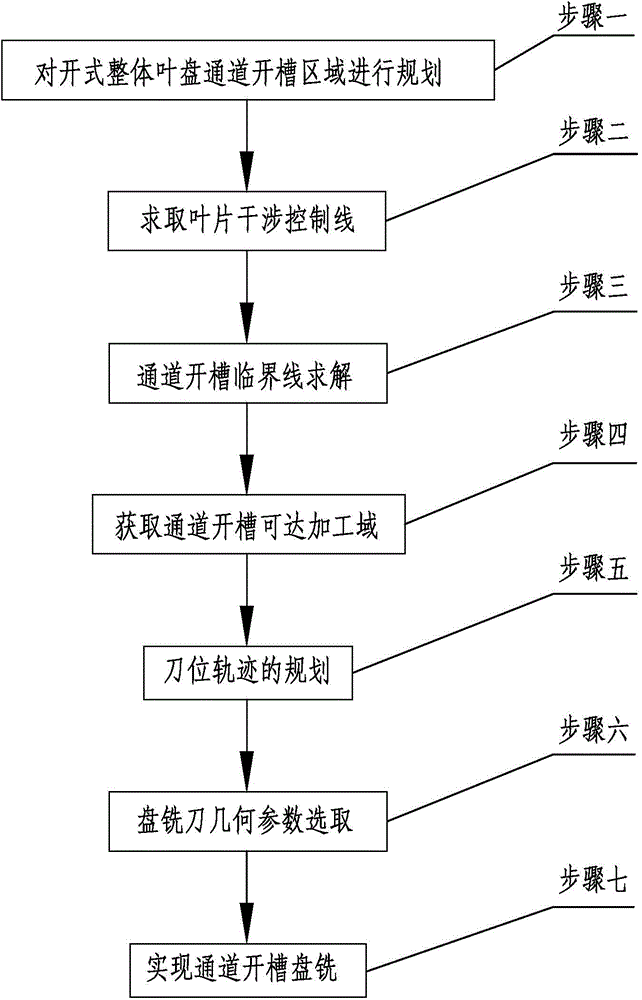

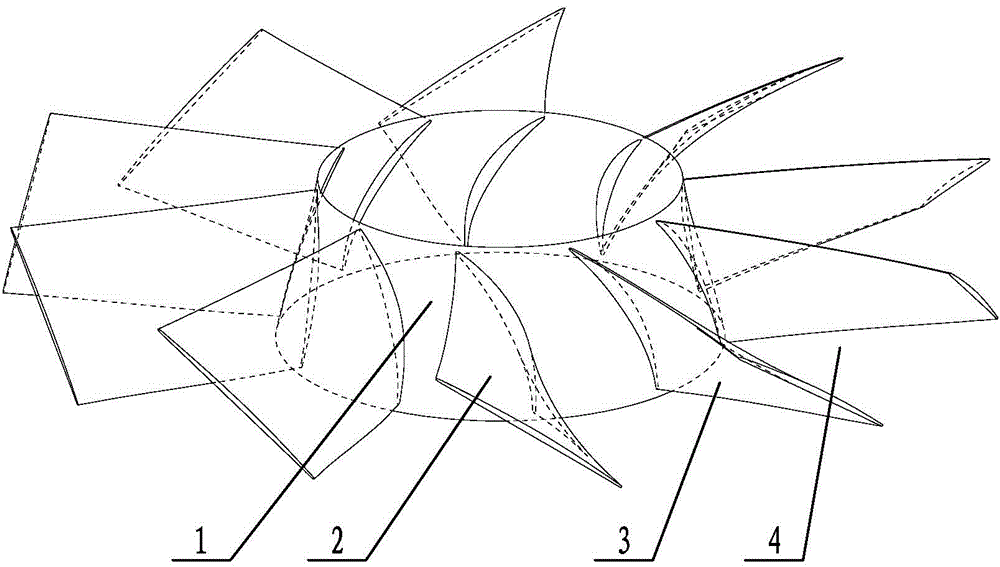

[0037] Specific implementation mode one: as Figure 1-Figure 6 As shown, an open-type blisk disc milling and slotting processing method according to this embodiment, the open-type blisk disc milling and slotting processing method includes the following steps:

[0038] Step 1: Plan the grooved area of the open blisk channel;

[0039] First define a set of sectional planes perpendicular to the axis of the blisk, and then intercept a set of ring curves intersecting the surface of the blisk channel ring hub (the channel ring hub is the ring hub part in the channel), and in this set of ring curves Find the point with the largest distance from the blisk axis; pass this point and the plane of the blisk axis, and then draw a straight line through the said point in this plane, so that the straight line is parallel to the blisk axis; then use this line as the generatrix Rotate around the axis of the blisk to get the slotted inner ring surface of the blisk; divide the blade into a con...

specific Embodiment approach 2

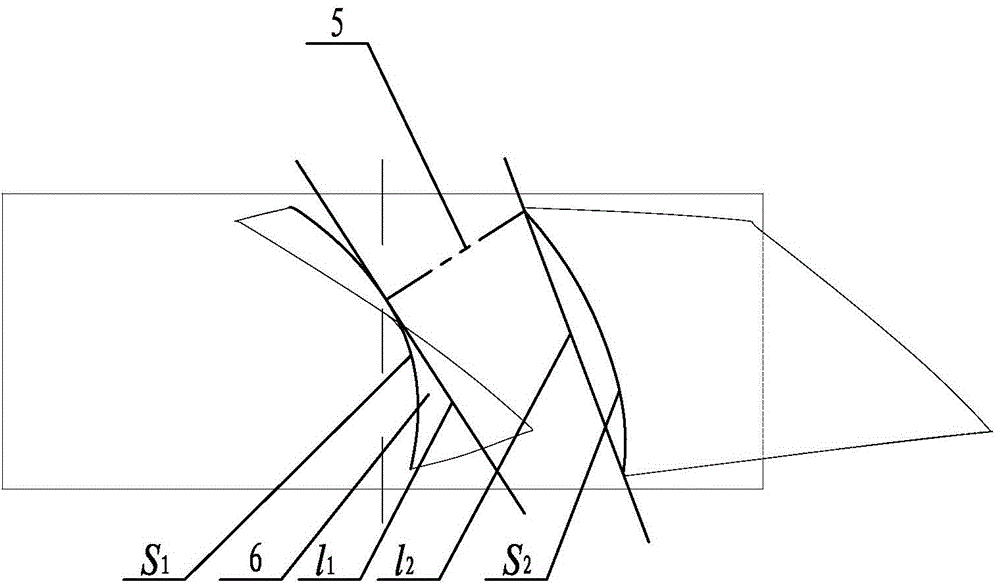

[0055] Specific implementation mode two: combination image 3 Note that in step 2 of this embodiment, the calculation of the length of the blade interference control line 5 is calculated by the method of calculating the minimum distance between curved surfaces based on the principle of surface geometry or based on UG computer-aided design software. The obtained blade interference control line 5 has a length of 19.73mm. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0056] Specific implementation mode three: in step six of this embodiment, the blade width E of the supporting blade of the cutter body is determined by the blisk material and the offset surface-L in step five 11 parallel to the plane-L 01 , select the offset surface 2 L 22 with parallel plane II L 02 The geometric spacing (fixed groove spacing) is 10mm, so that E<10+nε. The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com