A corrugated paper production process

A production process and technology of corrugated paper, which is applied in the field of corrugated paper manufacturing, can solve the problems such as the inability of the core paper to stick, and achieve the effect of neat cutting and tighter bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]In order to make the techniques, creative characteristics of the present invention, it is easy to understand that the present invention is further illustrated in connection with specific embodiments.

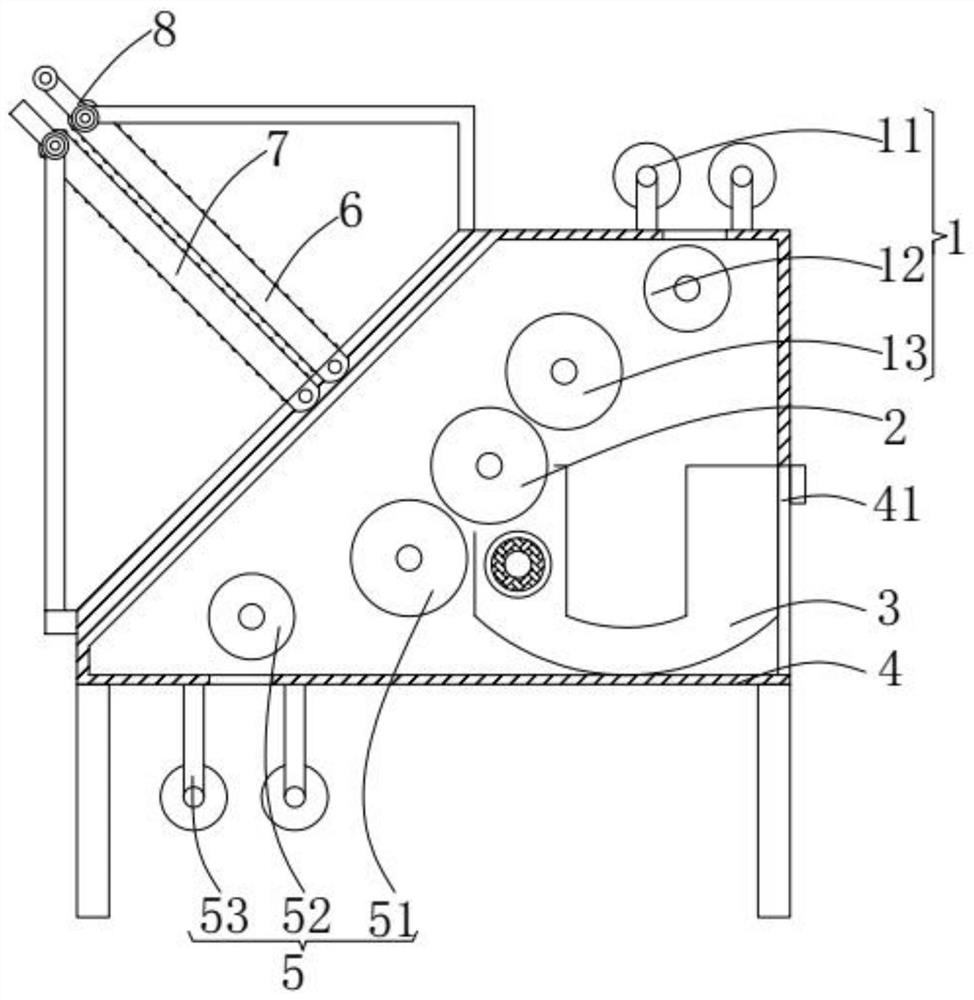

[0034]Such asfigure 1 As shown, a corrugated production process according to the present invention includes the following steps:

[0035]S1, put the core paper into the upper glueing equipment, the upper glue suppression equipment is pressed with the multilayer core paper, and the upper glue is completed;

[0036]S2, putting the molded corrugated paper in S1 is placed in a drying device for drying;

[0037]S3, put the corrugated paper dried in S2 into the cutting equipment, and the cutting equipment cuts the required corrugated paper under the set size;

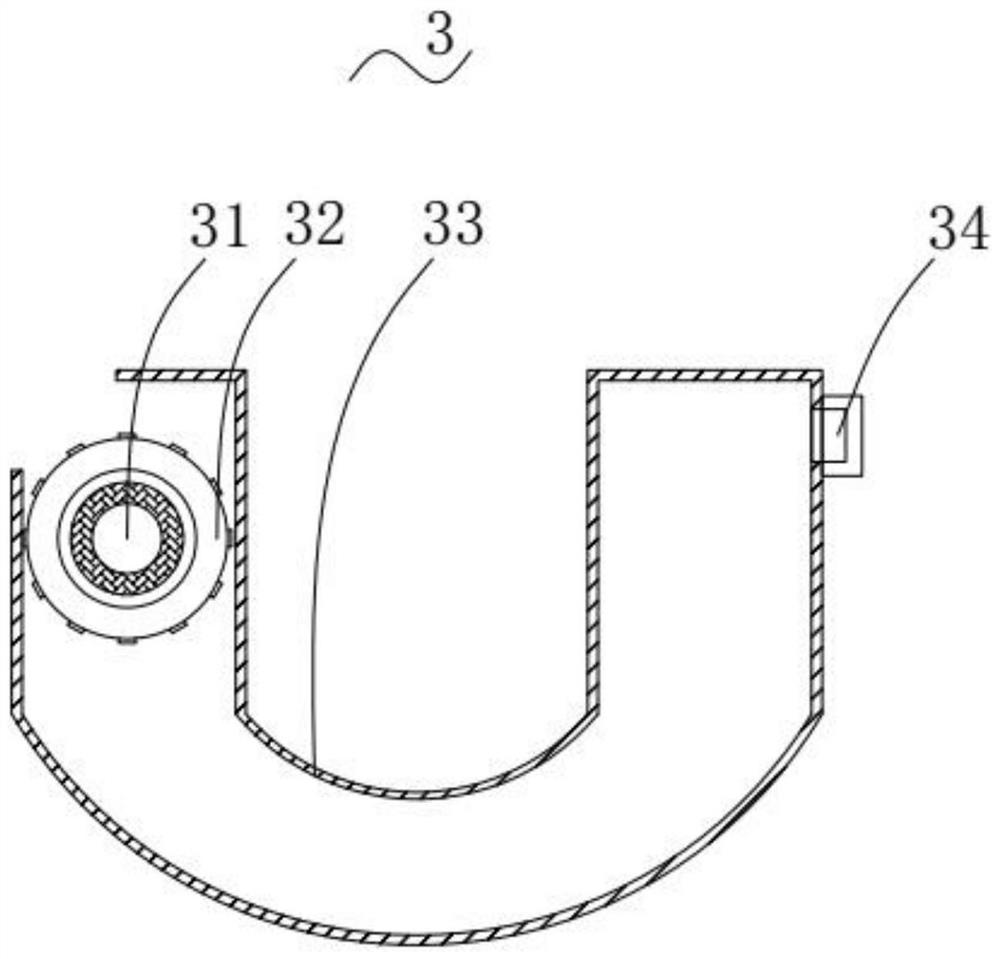

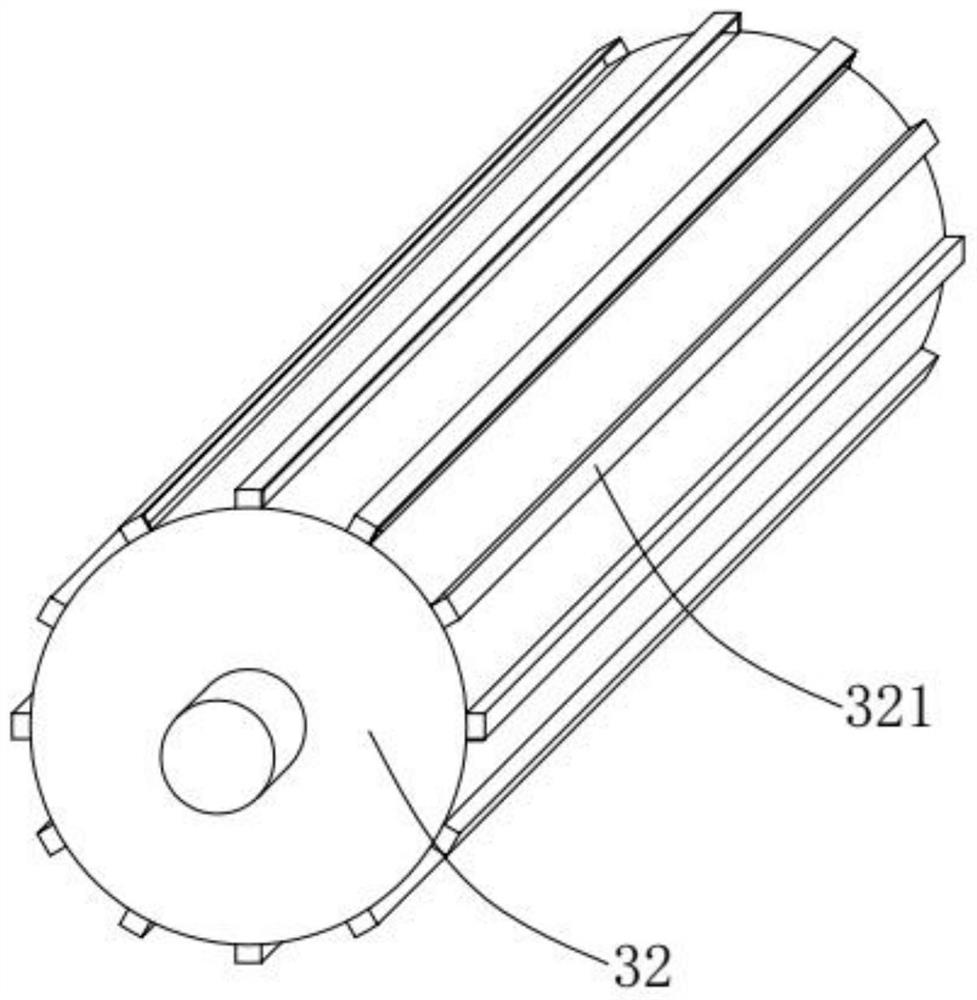

[0038]The upper glueing apparatus employed in this process includes a first conveying mechanism 1, a core wheel 2, a coating assembly mechanism 3, a housing 4, a second transport mechanism 5, a first press mechanism 6, a second press mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com