Liquid membrane dust suppression device

A liquid film and solution technology, which is applied in the directions of safety devices, dust prevention, and dust removal, can solve the problems of easy blockage of the mesh of the vibrating screen, insufficient moisture, secondary pollution of the environment, etc., and achieve the effect of dust suppression Ideal, good for health, economical improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the liquid film dust suppression device according to the present invention will be described in detail with reference to the accompanying drawings. It should be pointed out that the solid materials mentioned in this application include rock, cement concrete, scrap metal, construction and electronic waste, etc., and "rock" should be defined in a broad sense: "Rock is a naturally formed product that is formed by a A solid aggregate composed of one or more minerals".

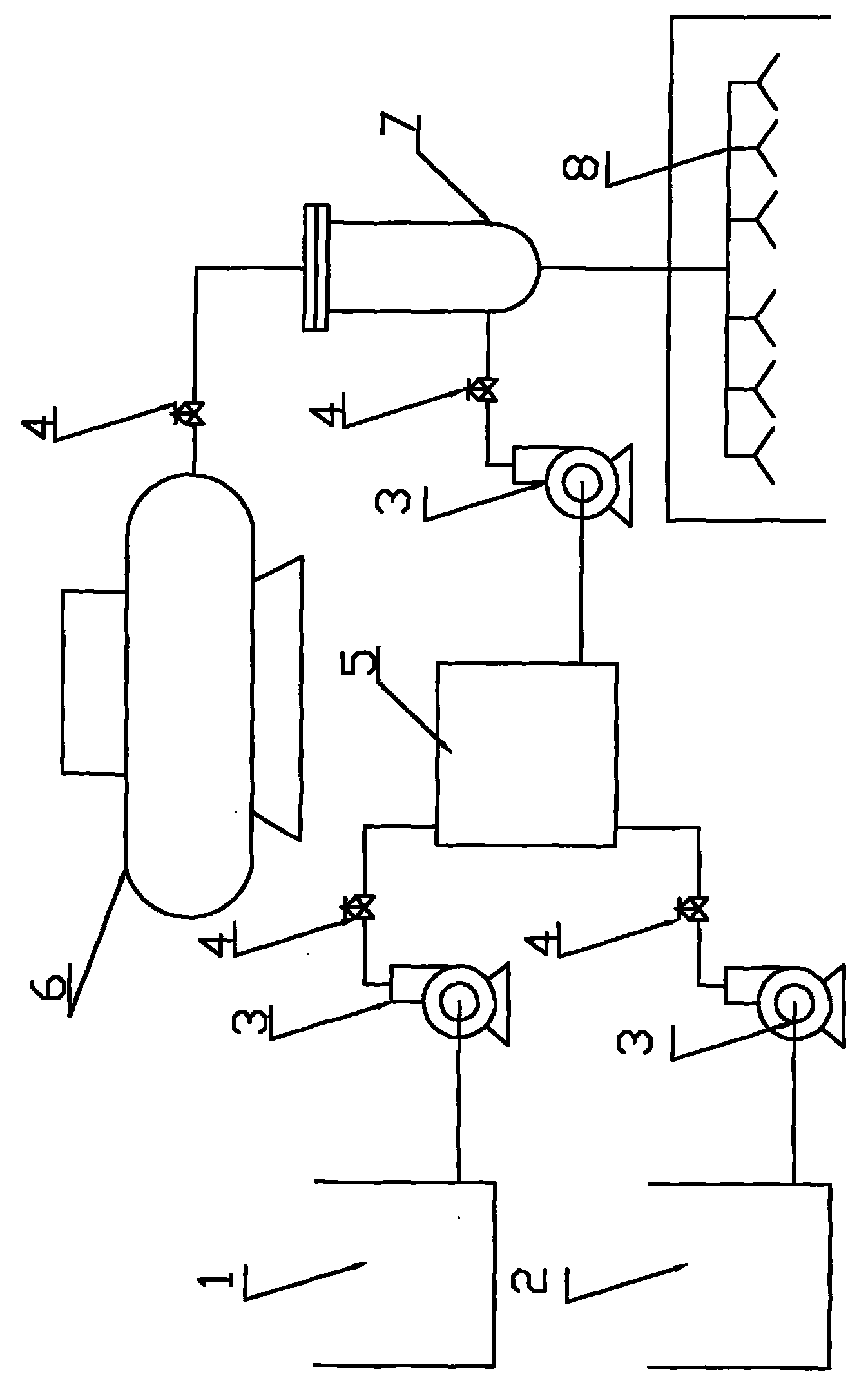

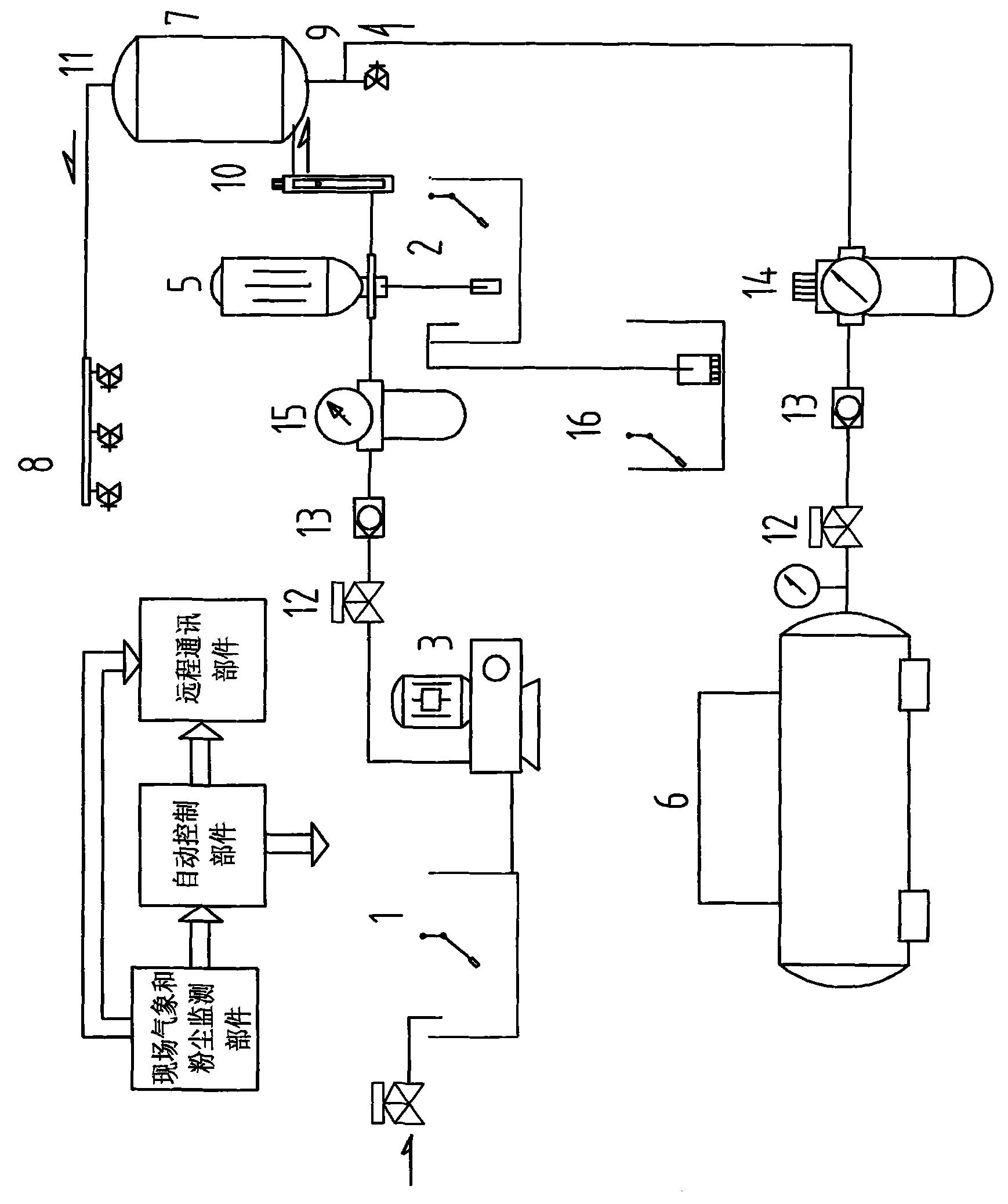

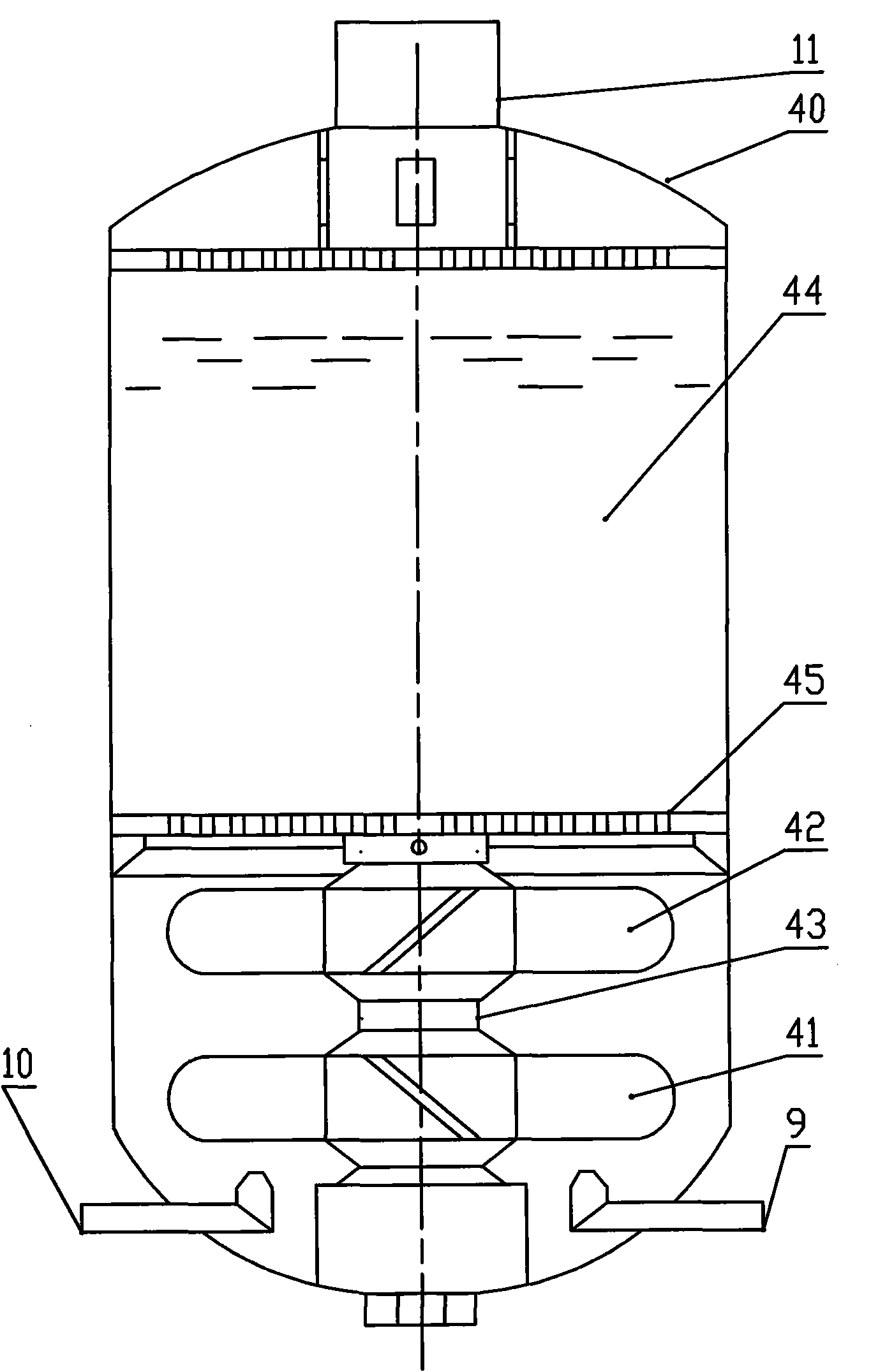

[0030] like figure 1 As shown, the dust suppression solution preparation part is mainly composed of a water tank 1, a dust suppression stock solution storage tank 2 and a precise proportion mixing device 5. The dust stock solution storage tank 2 is supplied to the precise proportion mixing device 5 through the pump 3 and the valve 4 in another branch, and the water and the dust suppression stock solution are supplied to the liquid film generator 7 after being mixed by the precise proportion mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com