Nano-silver sol and preparation and purification method thereof

A technology of nano silver sol and purification method, applied in the field of nano silver sol and its preparation and purification, can solve the problems of complex process requirements, high cost, difficult purification of nano silver sol, etc. The effect of less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

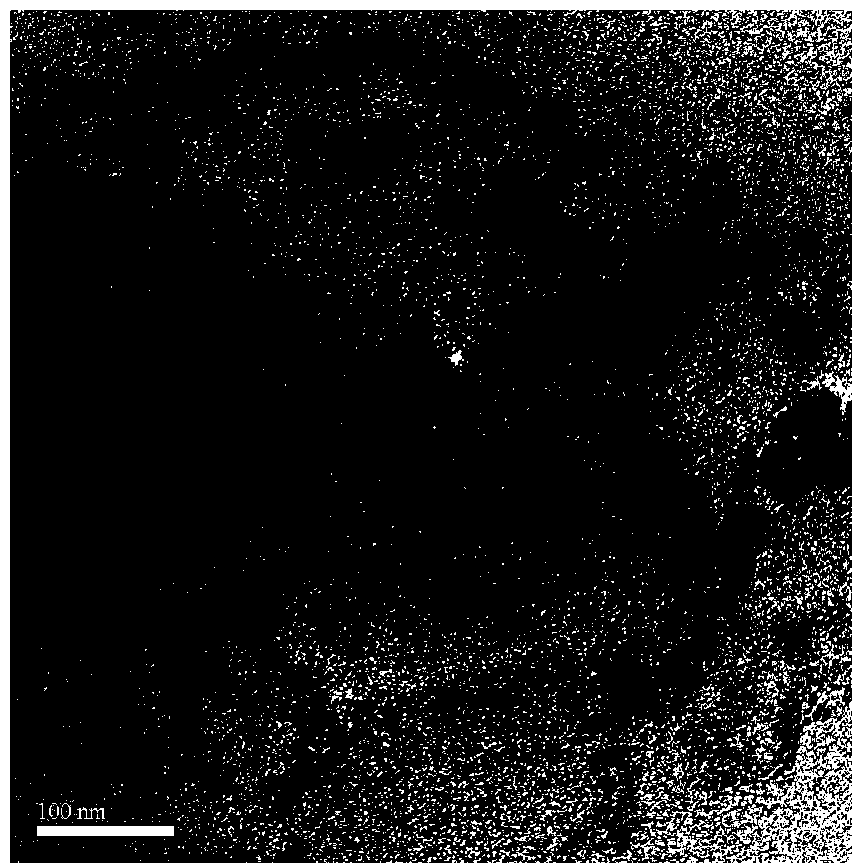

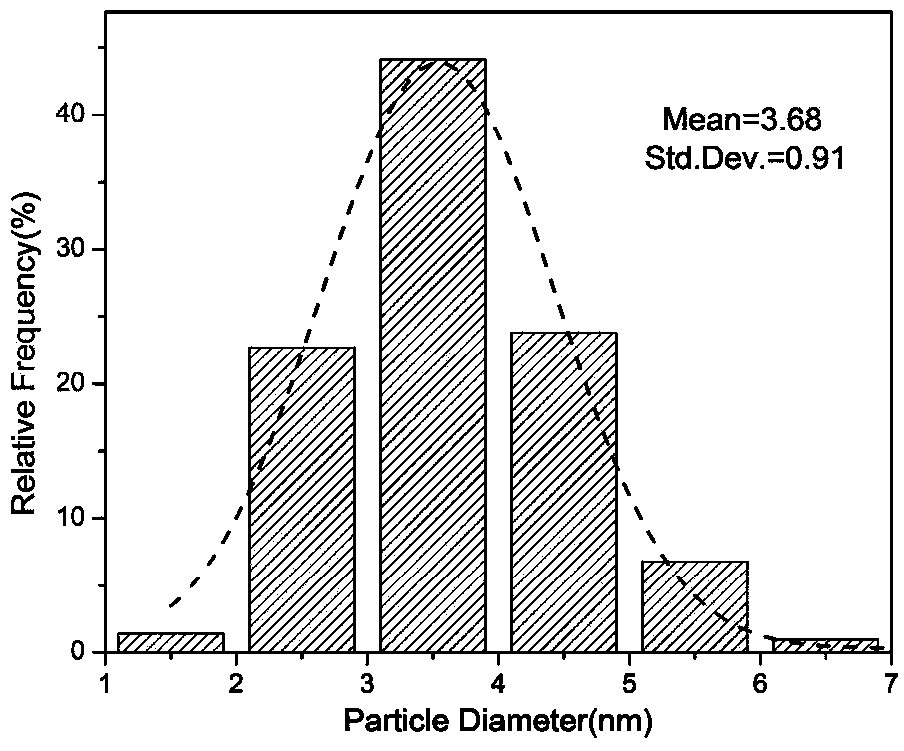

Image

Examples

preparation example Construction

[0021] The invention relates to a preparation and purification method of nano silver sol, which is characterized in that the steps of the method are as follows: using silver salt, protective agent and cosolvent, using water as solvent, mixing silver salt solution and protective agent aqueous solution, adding a certain A certain amount of reducing agent is reduced to obtain the initial nano-silver sol, and an appropriate amount of pH regulator is added to the sol, and the required concentration of nano-silver sol is obtained after adjusting the pH value, precipitation, separation, washing, and redissolution, and is characterized in that , nano silver particle size controllable, uniform distribution, adjustable sol concentration.

[0022] Concrete preparation steps are as follows:

[0023] 1. Prepare a certain concentration of protective agent solution:

[0024] Weigh a certain amount of protective agent, add it into water containing an appropriate amount of co-solvent, stir fo...

Embodiment 1

[0036] The silver salt adopts silver nitrate, the protective agent adopts chitosan, the cosolvent adopts glacial acetic acid, the reducing agent adopts sodium borohydride, the pH value regulator adopts sodium hydroxide, and water is the solvent. After dissolving, mixing, reducing, adjusting the pH value, After precipitation, separation, washing, and redissolution, 5 ppm of stable nano-silver sol was obtained. Concrete preparation steps are as follows:

[0037] 1. Prepare chitosan acetic acid solution: add 500ml of water to a glass container, add 10ml of glacial acetic acid, stir for 5-10 minutes, mix well, weigh 4g of chitosan and add it to the aforementioned acetic acid aqueous solution, and stir for 3 to 5 hours , until the solution is clarified to obtain a certain concentration of chitosan solution as a protective agent solution;

[0038] 2. Ag + Preparation of solution: Weigh 0.1574g of silver nitrate, add 500ml of water, stir for 10 minutes to obtain silver nitrate soluti...

Embodiment 2

[0047] The silver salt is silver acetate, the protective agent is chitosan, the cosolvent is formic acid, the reducing agent is potassium borohydride, the pH regulator is sodium hydroxide, and water is the solvent. After dissolution, mixing, reduction, adjustment of pH, precipitation , separation, washing and redissolving to obtain 5000ppm stable nano-silver sol. Concrete preparation steps are as follows:

[0048] 1. Prepare chitosan formic acid solution: add 500ml of water to a glass container, add 5ml of formic acid, stir for 5 to 10 minutes, mix well, weigh 1g of chitosan and add it to the aforementioned formic acid aqueous solution, stir for 3 to 5 hours, Until the solution is clear, a certain concentration of chitosan solution is obtained as a protective agent solution;

[0049] 2. Ag + Preparation of the solution: Weigh 0.3095g of silver acetate, add 500ml of water, and stir for 10 minutes to obtain a silver acetate solution as Ag + solution;

[0050] 3. Mix the chit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com