Centrifugal device based on copper powder separating

A technology of centrifugal equipment and copper powder, applied in centrifuges with rotating drums, centrifuges, etc., can solve the problems of increased cost, difficult maintenance, and large consumption of reagents, and achieve simple structure, good environment, and guaranteed purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

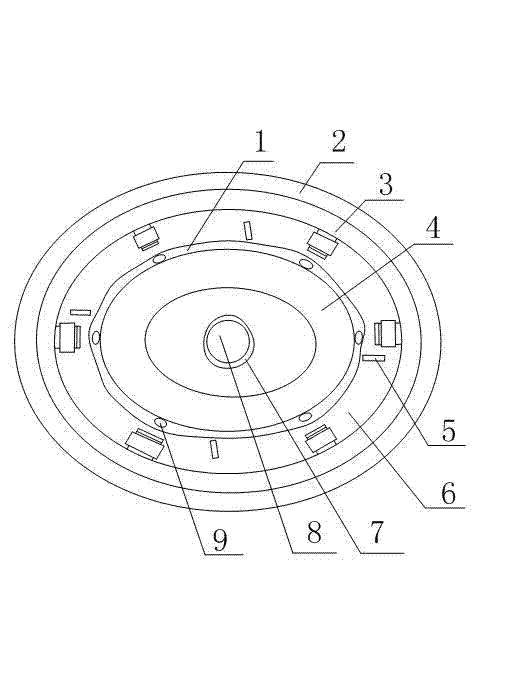

[0015] Such as figure 1 As shown, the centrifuge equipment based on the separation of copper powder includes a hollow shell 2, a rotating seat is arranged at the bottom center of the shell 2, the rotating seat is connected with a motor arranged outside the shell 2, and a filter cartridge is arranged on the rotating seat 3. Several through holes are provided on the wall of the filter cartridge 3, and the filter cartridge 3 is provided with a fixed ring 6 and a filter screen 1 inside, and the fixed ring 6 is fixed with the filter cartridge 3, and the surrounding of the filter screen 1 is connected with the fixed ring The inner wall of 6 is connected. The motor drives the rotating seat to rotate, and the filter cartridge 3 rotates with the rotating seat, and then the copper powder liquid inside the filter screen 1 is filtered through the small holes of the filter screen 1, the copper powder remains on the filter screen 1, and the liquid passes through the side wall of the filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com