Infrared detector structure for improving spectral flatness

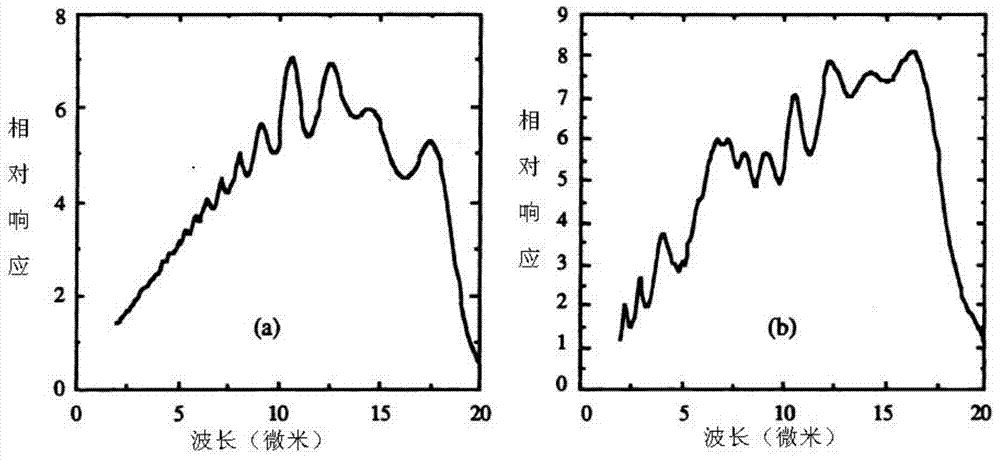

An infrared detector and flatness technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of unsatisfactory response flatness, not taking into account the fluctuation of infrared photons, and the influence of light field distribution in photosensitive areas, etc. Good flatness, structure and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

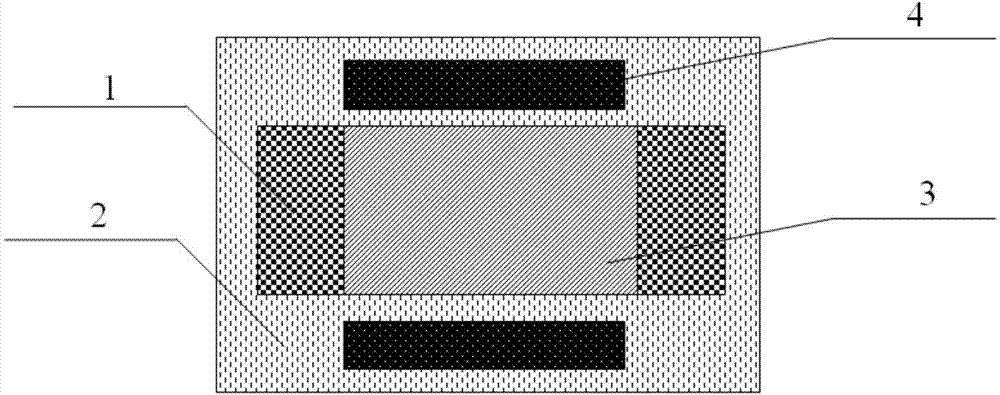

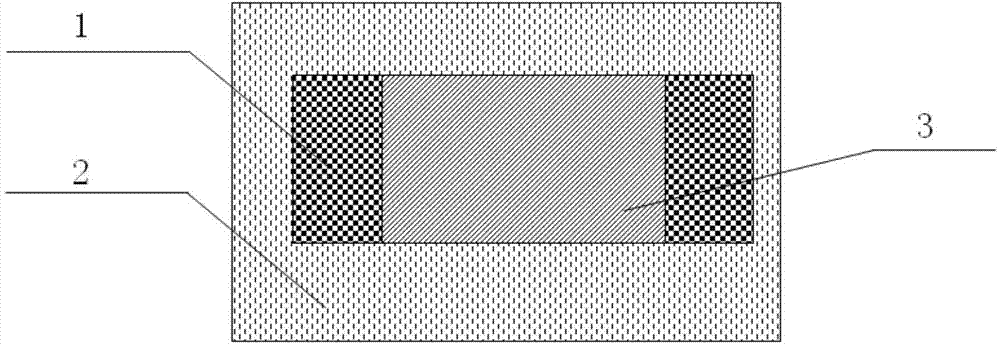

[0033] Combine below figure 2 Specific embodiments of the present invention will be described in detail.

[0034] 1. The distance between the photosensitive area 3 and other dielectric areas 4 generally does not exceed the peak wavelength of the infrared detector response, and within the range allowed by the lithography precision and process conditions, the smaller the better.

[0035] 2. For other dielectric regions 4, in practice, the same material as that of the photosensitive region 3 is generally selected, for example, both are HgCdTe materials, and anti-reflection coatings with the same thickness and medium are grown on the surfaces of the photosensitive region 3 and other dielectric regions 4 , and then use an etching or etching process for electrical isolation. In this way, the reflection of infrared photons on the surface of the photosensitive area 3 and other medium areas 4 and the interference phenomenon between them are greatly weakened.

[0036] 3. The geometri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com