Over-current protection device and method for manufacturing the same

A technology for protecting components and manufacturing methods, applied in electrical components, resistor manufacturing, resistor components and other directions, can solve problems such as difficulty in meeting the requirements of handheld electronic products, inability to balance adhesion strength and overall component thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above-mentioned and other technical content, features and advantages of the present invention more obvious and understandable, the following specifically cites relevant embodiments, together with the attached drawings, for detailed description as follows:

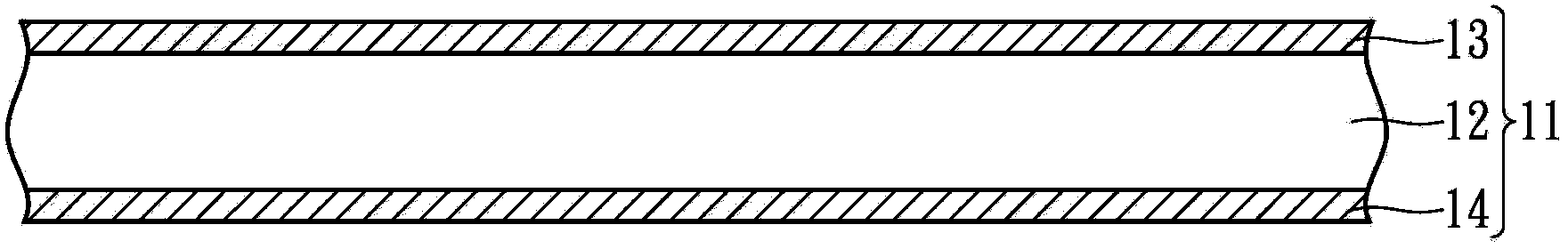

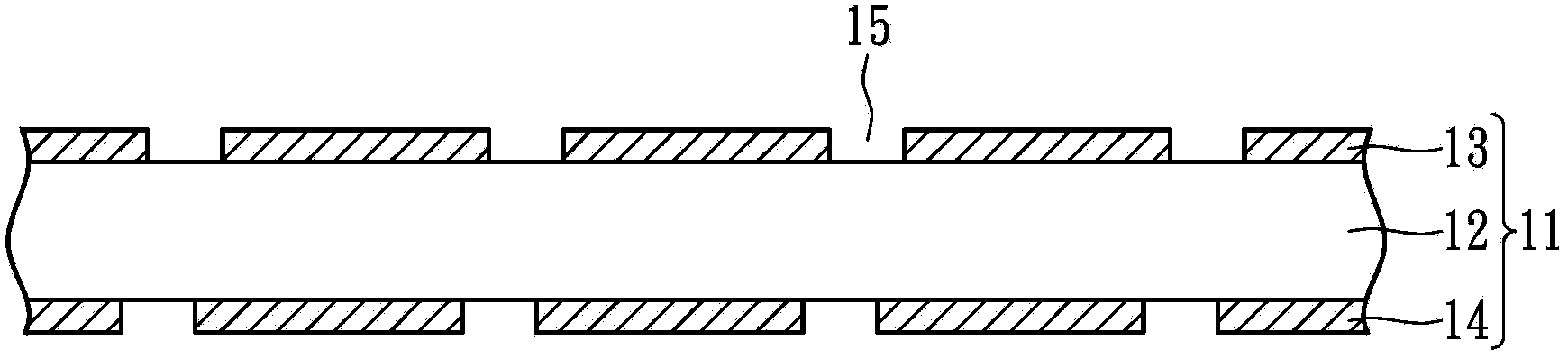

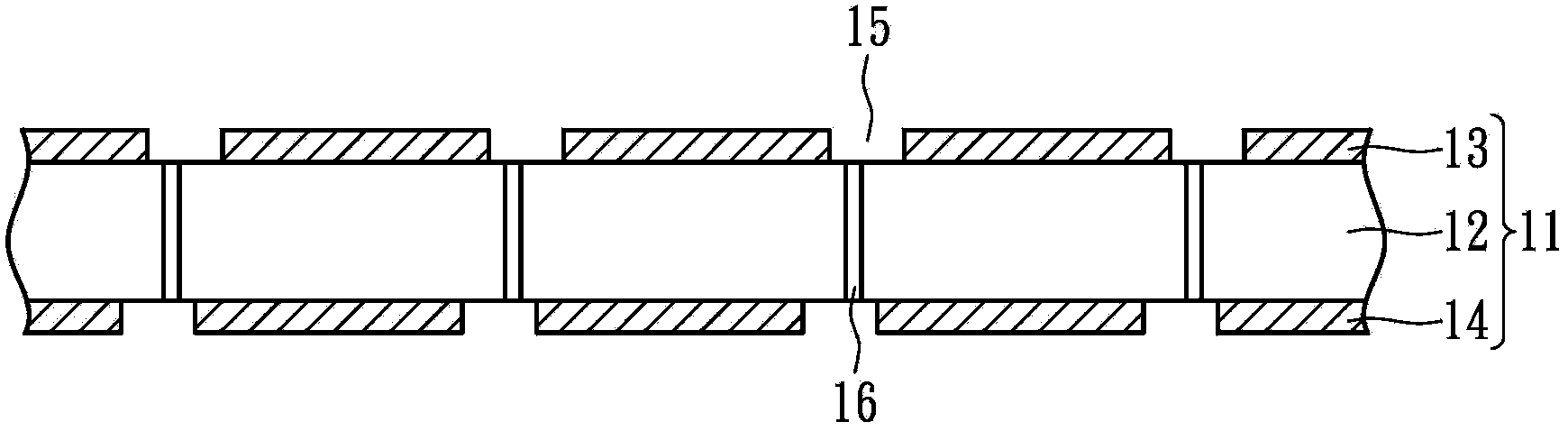

[0030] refer to figure 1 , providing a PTC substrate 11, the PTC substrate 11 includes conductive members 13, 14 and a PTC material layer 12 stacked therebetween. In one embodiment, the PTC material layer 12 includes a crystalline polymer and conductive fillers dispersed in the crystalline polymer. Crystalline polymers can be selected from crystalline polyolefin polymers (such as high-density polyethylene, medium-density polyethylene, low-density polyethylene, polyethylene wax, ethylene polymer, polypropylene, polyvinyl chloride or polyvinyl chloride) Vinyl fluoride, etc.), copolymers of olefinic monomers and acrylic monomers (such as ethylene-acrylic acid copolymers, ethylene-acrylic copolymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com