Ultrasonic testing device for circumferential weld of cylinder of nuclear reactor pressure vessel

A technology for nuclear reactors and pressure vessels, which is applied to nuclear reactor monitoring, reactors, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc. It can solve problems such as welds that are prone to corrosion, slag inclusions, and coolant leakage, and improve accuracy and reliability. Sexuality, reduction in radiation exposure, and reduction in the number of pallet replacements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

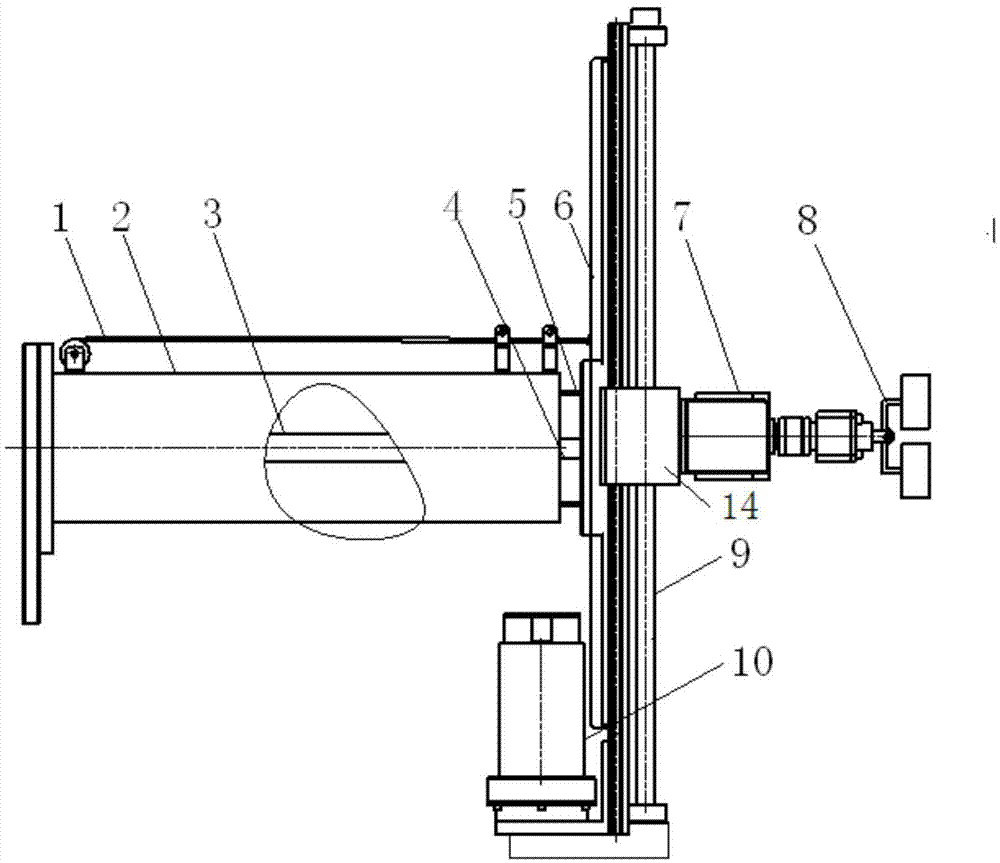

[0012] A nuclear reactor pressure vessel shell girth weld ultrasonic inspection device according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

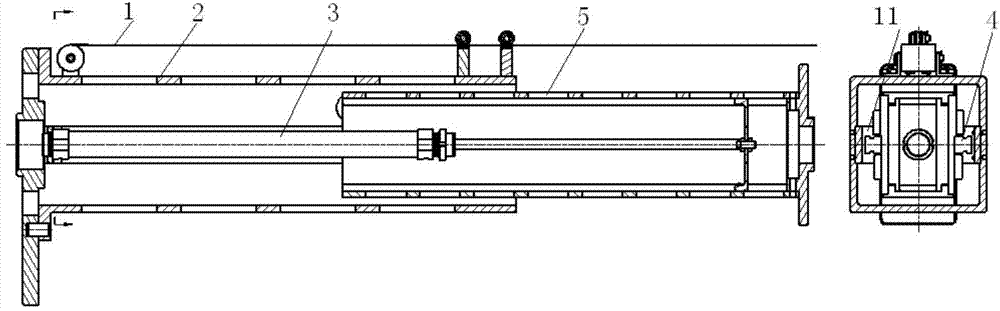

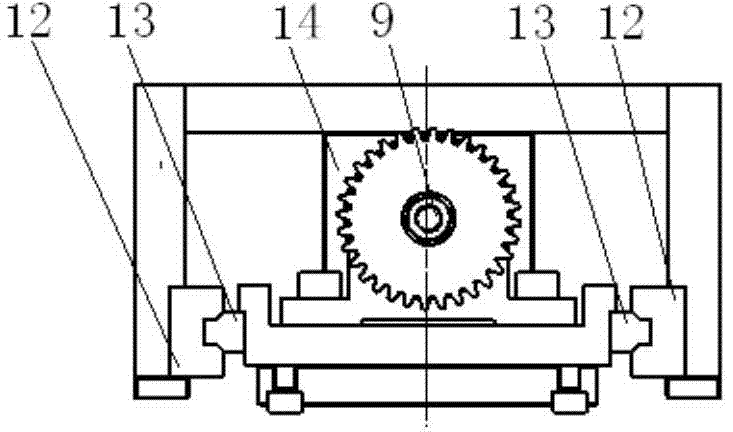

[0013] like figure 1 As shown in the present invention, a nuclear power plant nuclear reactor pressure vessel cylinder girth weld ultrasonic inspection device includes a vertically arranged ball screw 9, a nut seat 14 sleeved on the ball screw 9, a drive element 10 and The ball screw 9 is connected with each other, and the ball screw 9 is driven to rotate through the forward and reverse rotation of the driving element 10, so as to realize the movement of the nut seat 14 up and down. The ball screw 9 and the driving element 10 are fixed on the bottom plate 6 .

[0014] One side of the bottom plate 6 is fixed at one end of the inner sleeve 5, and the inner sleeve 5 is connected to the telescopic cylinder 3, and the inner sleeve 5 and the telescopic cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com