Measuring method for quantification of central looseness of casting blank

A measurement method and technology of center porosity, applied in the technical field of quantitative evaluation of slab center porosity, can solve problems such as inability to observe center porosity, cumbersome operation, limited guiding significance, etc., achieve small human influence factors, simple operation and equipment , the result is intuitive and clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principle of the present invention will be systematically described below in conjunction with the accompanying drawings, and the specific implementation will be explained in detail.

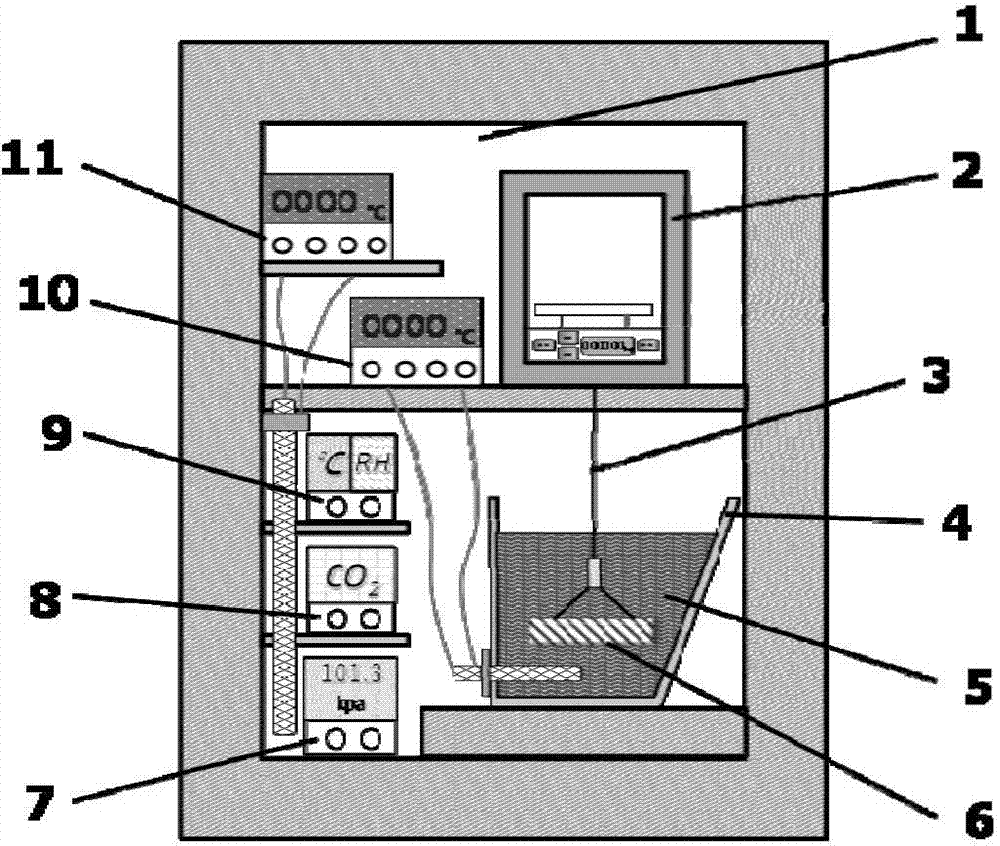

[0039] figure 1 It is a schematic diagram of equipment for quantitative density measurement of central looseness involved in the present invention, and its density measurement principle is as follows:

[0040] According to Archimedes' principle, it can be known that the density of a solid sample can be obtained by calculation by weighing in a liquid. However, considering the influence of temperature and air etc. on the density of the solid sample, the density measurement method involved in the present invention comprehensively considers each influencing factor, and the calculation formula for obtaining the density of the sample solid is as follows:

[0041] ρ t = m at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com