A side suction range hood

A range hood and smoke collection technology, which is applied in the direction of oil fume removal, heating methods, household heating, etc., can solve the problems of high cost, increased oil fume, non-energy saving and environmental protection, etc., to increase the design space, increase the power of the motor, and improve the The effect of smoking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

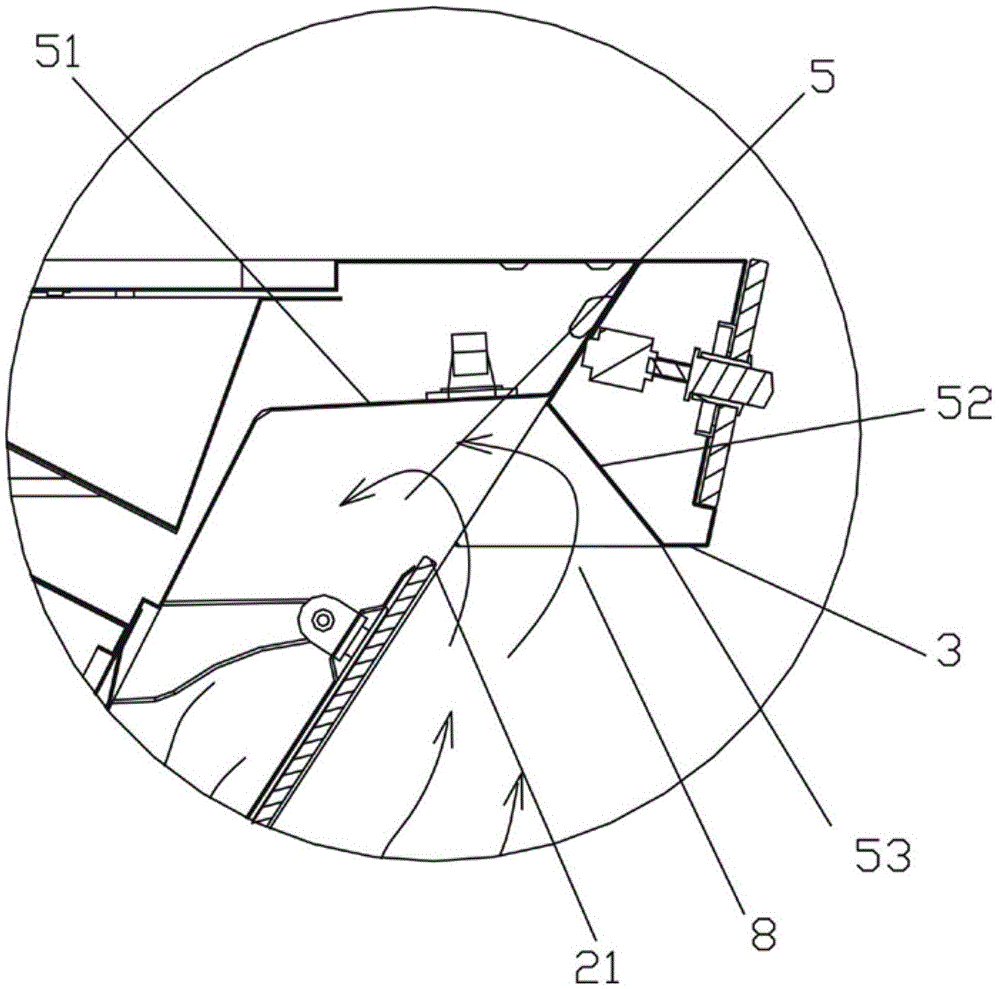

[0026] Such as Figure 2 to Figure 4 , a side suction range hood, including a smoke collecting hood 1 with an air inlet 11 and a fan system 7 located behind the smoke collecting hood 1, the air inlet 11 communicates with the fan system 7, and a smoke guide is arranged in front of the air inlet 11 Plate 2, the gap between the smoke collecting hood 1 and the smoke guide plate 2 forms a smoke collecting cavity 4, a top plate 3 is arranged above the smoke collecting hood 1, and an upwardly recessed smoke collecting buffer chamber 5 is provided on the top plate 3, and the smoke collecting buffer The chamber 5 communicates with the smoke collection chamber 4, the volume of the smoke collection buffer chamber 5 is 2L-12L, and the maximum suction volume of the range hood per second is 150L / s-350L / s. In order to improve the defects of the prior art, the present invention adopts an upwardly recessed smoke collection buffer chamber 5 on the top plate 3, and the smoke collection buffer ch...

Embodiment 2

[0034] The difference between this embodiment and Embodiment 1 is that the volume of the smoke-collecting buffer chamber 5 is 10L, as Figure 5 , the range hood has a casing 6, the top plate 3 is recessed upwards to form a smoke collection buffer chamber 5, and the casing 6 of the range hood forms an upwardly protruding boss 61 to match the volume of the smoke collection buffer chamber 5. The boss design increases the design space of the smoke collecting buffer chamber 5. In this embodiment, due to the use of a large-volume smoke-collecting buffer chamber 5, a small value is selected for the maximum suction volume of the range hood per second, which can satisfy the effective smoke absorption effect of the range hood and reduce the impact on the range hood. Motor power requirements, in this embodiment, the maximum suction volume per second of the range hood is designed to be 200L / s, the area surrounded by the upper edge 21 of the smoke guide plate 2 and the lower edge 53 of the...

Embodiment 3

[0036] The difference between this embodiment and Embodiment 1 is that the volume of the smoke-collecting buffer chamber 5 is 2L. In the embodiment, the maximum suction volume per second of the range hood is designed to be 300 L / s, and the area S surrounded by the upper edge of the smoke guide plate 2 and the lower edge of the smoke collecting buffer chamber 5 is designed to be 5.1 cm 2 , the L1 is 180 mm, and the included angle between the smoke guiding wall 52 and the horizontal direction is 30°. This embodiment adopts a small-volume smoke-collecting buffer chamber 5, which reduces the influence of the volume of the smoke-collecting buffer chamber 5 on the shape of the range hood, and this embodiment does not set the maximum suction volume of the range hood as V per second. The setting is very high, and the more conventional suction volume of 250L / s on the market can meet the full collection of oil fume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com