Light-emitting diode (LED) lamp heat dissipation and waste heat recovery device

A waste heat recovery device, LED lamp technology, applied in lighting devices, cooling/heating devices for lighting devices, lighting and heating equipment, etc. The effect of accelerated heat dissipation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

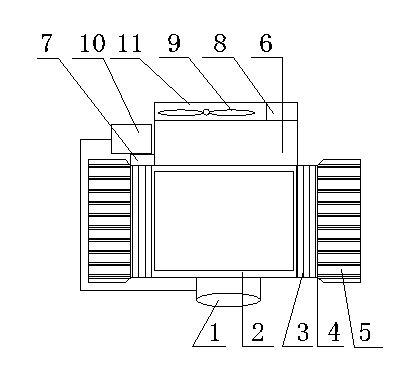

[0011] figure 1 It is a schematic diagram of the structure of the present invention, which includes LED lamp 1, inner substrate 2, chip thermoelectric converter 3, outer substrate 4, heat dissipation fins 5, heat pipe radiator 6, output wire 7, fan connector 8, heat dissipation fan 9. The energy storage conversion unit 10 and the net cover 11, the LED lamp is connected to the inner substrate 2, and the two sides of the inner substrate 2 are provided with cooling fins 5, and the cooling fins 5 are connected to the sheet-type thermoelectric converter 3, The inner substrate 2 is provided with a heat pipe radiator 6, the heat pipe radiator 6 is provided with a cooling fan 9, the cooling fan 9 is connected to the fan connector 8, and one side of the heat pipe radiator 6 is provided with an energy storage A conversion unit 10 , the energy storage conversion unit 10 is connected to the output wire 7 . The heat dissipation fins 5 are connected to the inner substrate 2 through the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com