High-efficiency needleless coaxial electrostatic spinning device and method

A coaxial electrospinning, needle-free technology, applied in textile and papermaking, filament/thread forming, fiber processing, etc., can solve the problem of no coaxial electrospinning device, and achieve continuous and large-scale The effect of producing, avoiding easy clogging, and avoiding needle clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

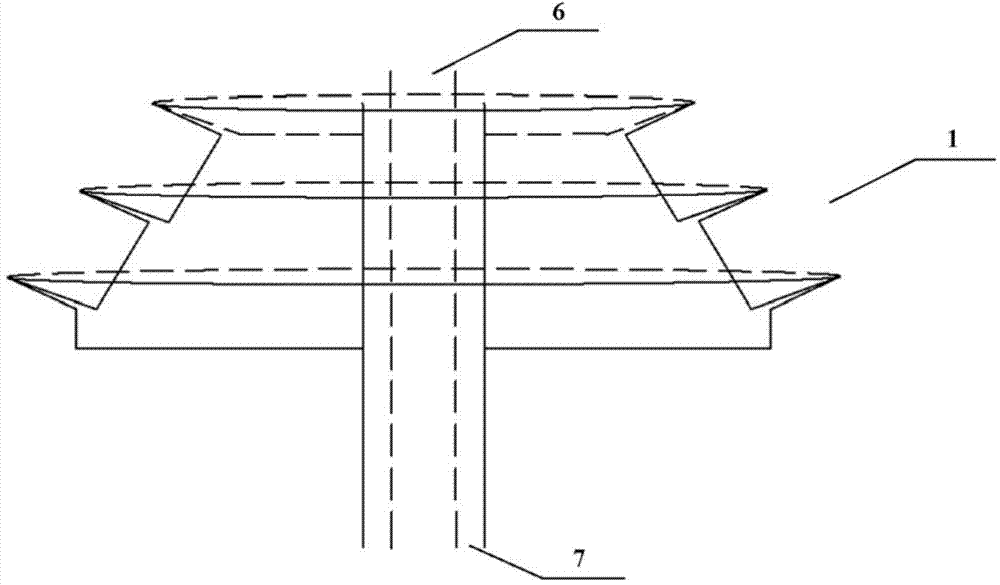

[0032] use figure 1 The high-efficiency needle-free coaxial electrospinning device shown is used for coaxial electrospinning. The core solution is 8% polyacrylonitrile (PAN) solution, and the shell solution is 12% polyurethane (PU) solution. , the output end of the liquid storage container with the core layer solution is placed in the middle cylindrical hollow outer tube 7 of the ladder-shaped needle-free nozzle 1, and the output end of the liquid storage container with the shell solution is placed in the ladder-shaped needle-free nozzle 1 In the central cylindrical hollow inner tube 6, the core spinning solution and the shell spinning solution are left from the top layer of the ladder-shaped needle-free nozzle 1 along the surface of the ladder-shaped needle-free nozzle from top to bottom under the action of their respective propellers, The edges of each layer of the ladder-shaped needle-free nozzle are covered with two layers of spinning solution. At this time, the voltage o...

Embodiment 2

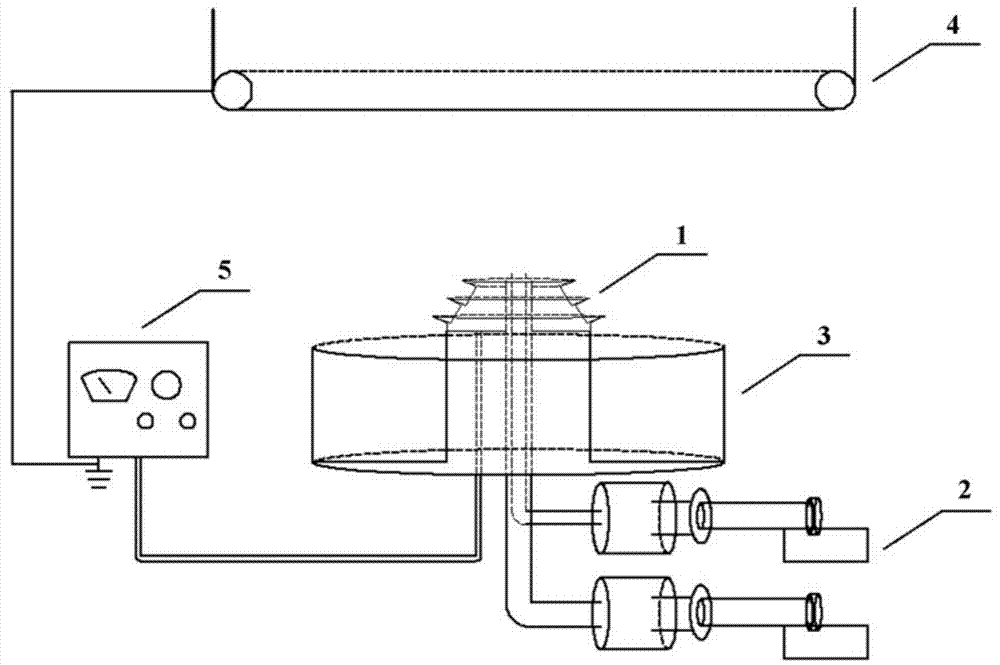

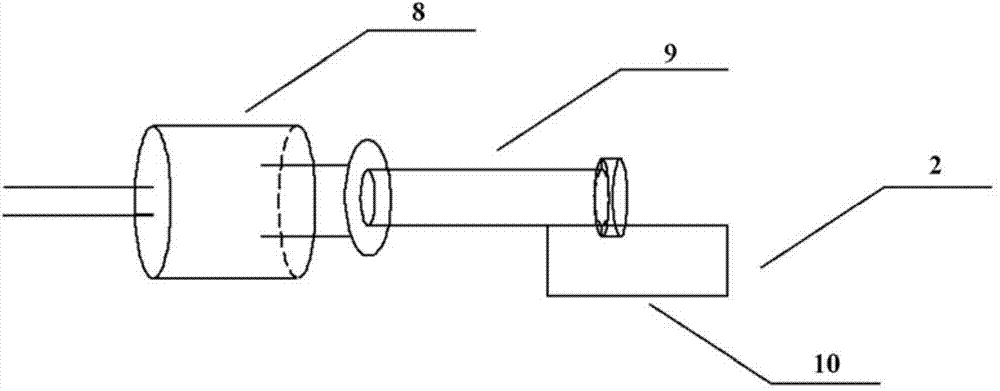

[0034] like figure 1 and figure 2 As shown, a high-efficiency needle-free coaxial electrospinning device includes five parts: a stepped needle-free spinneret 1, a liquid supply system 2, a solution recovery tank 3, a receiving device 4, and a high-voltage electrostatic generator 5. It is characterized in that the receiving device 4 is provided above the stepped needle-free spinneret 1, and a solution recovery tank 3 is placed at the bottom of the stepped needle-free spinneret 1, and the stepped Below the needle-free spinneret 1, there is a terminal connected to the high-voltage generator 5; the center of the stepped needle-free spinneret 1 is a hollow place, and the output end of the liquid supply system 2 is placed into The hollow part of the stepped needle-free spinneret 1; the stepped needle-free spinneret 1 is circular and stepped, with a three-layer structure, and the diameter gradually increases from the top layer to the bottom layer. The inner side of the layer edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com