Method for hydrothermally synthesizing analcime monocrystal

A synthetic method, analzem technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of long preparation time and high energy consumption, and achieve simple and easy-to-control reactions, mild reaction conditions, and high-quality products. relatively simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

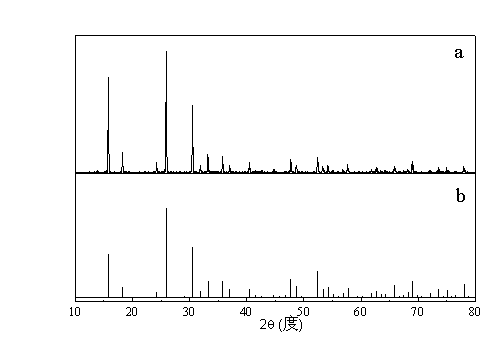

Embodiment 1

[0011] Weigh 3.865 g of solid NaOH and dissolve it in 160 mL of distilled water, put it into a beaker, add 1.201 g of Si powder at the same time, stir and react for 5 h at a water bath temperature of 90 °C to obtain a sodium silicate solution; weigh 1.947 g of solid NaOH and dissolve in Put 50 mL of distilled water into a beaker, add 0.576 g of Al powder, stir and react at room temperature to obtain a sodium metaaluminate solution; filter the sodium silicate solution and the sodium metaaluminate solution with filter paper, stir and mix, and then microwave Heating at 700 W and 90 °C for 0.5 h under the condition of full stirring, the precursor was obtained as a white gel; the precursor gel obtained in the above steps was added to the autoclave with a filling rate of 70%, and the reaction was carried out at a constant temperature of 200 °C for 3 d. After the reaction, centrifugally filter and wash with water until neutral; dry in a constant temperature drying oven at 80 °C for 12...

Embodiment 2

[0017] Weigh 3.865 g of solid NaOH and dissolve it in 160 mL of distilled water, put it into a beaker, add 1.201 g of Si powder at the same time, stir and react for 5 h at a water bath temperature of 90 °C to obtain a sodium silicate solution; weigh 1.947 g of solid NaOH and dissolve in Put 50 mL of distilled water into a beaker, add 0.576 g of Al powder, stir and react at room temperature to obtain a sodium metaaluminate solution; filter the sodium silicate solution and the sodium metaaluminate solution with filter paper, stir and mix, and then microwave Heating at 700 W and 90 °C for 0.5 h under the condition of full stirring, the precursor was white gel; the precursor gel obtained in the above steps was added to the autoclave with a filling rate of 70%, and the reaction was carried out at a constant temperature of 200 °C for 6 d. After the reaction, centrifugally filter and wash with water until neutral; dry in a constant temperature drying oven at 80 °C for 12 h to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com