A kind of steel chemical pretreatment method and used pickling solution

A pickling solution and chemical technology, applied in the field of chemical pretreatment of steel, to achieve the effect of simple process, less process and lower equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

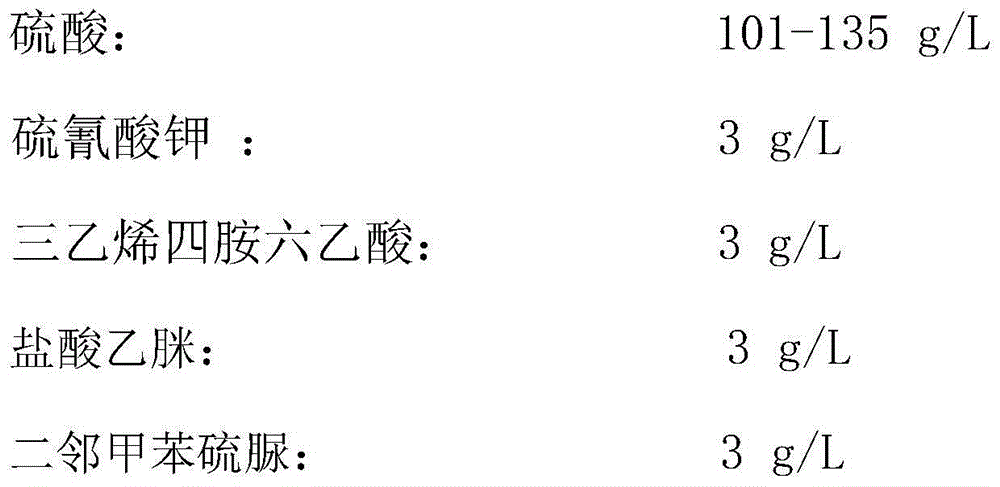

[0027] Prepare pickling solution:

[0028]

[0029] The mass concentration of sulfuric acid used was 19%.

[0030] The workpiece is immersed in the pickling solution prepared at 30°C for 5 minutes. The concentration of the surfactant anionic fatty alcohol polyoxyethylene ether sodium sulfate in the pickling solution is 10g / L. The rust on the steel surface is removed to expose the original metal color, and the liquid is drained for 2 minutes; Soak in the 30°C degreasing solution for 3 minutes. The degreasing solution contains coarse-grained alkali with a mass concentration of 25% and anionic polyacrylamide with a mass concentration of 0.5%. Temperature 30°C, soak for 1min, drain for 1min; soak in 30°C ferric molybdate phosphating solution for 3min, the surface of the treated workpiece will be colored.

Embodiment 2

[0032] Prepare pickling solution:

[0033]

[0034] The mass concentration of sulfuric acid used was 17%.

[0035] Soak the workpiece in the prepared pickling solution at 18°C for 4 minutes. The concentration of surfactant anionic fatty alcohol polyoxyethylene ether sodium sulfate in the pickling solution is 10g / L. The rust on the steel surface is removed to reveal the original color of the metal. Drain 2min; soak in 18°C degreasing solution for 4min, the degreasing solution contains coarse-grained alkali with a mass concentration of 35% and anionic polyacrylamide with a mass concentration of 0.3%. Water washing process, the temperature is 18°C, soaking for 1min, draining for 1min; soaking in 18°C iron molybdate phosphating solution for 4min, the surface of the workpiece after treatment is colored.

Embodiment 3

[0037] Prepare pickling solution:

[0038]

[0039] The mass concentration of sulfuric acid used was 15%.

[0040] The workpiece is immersed in the prepared pickling solution at 5°C for 3 minutes. The concentration of the surfactant anionic fatty alcohol polyoxyethylene ether sodium sulfate in the pickling solution is 10g / L. The rust on the steel surface is removed to reveal the original color of the metal. 2min; Soak in the degreasing bath at 5°C for 5min. The degreasing solution contains coarse-grained alkali with a mass concentration of 45% and anionic polyacrylamide with a mass concentration of 0.1%. Water washing process, the temperature is 5°C, soaking for 1min, draining for 1min; soaking in 5°C iron molybdate phosphating solution for 5min, the surface of the workpiece after treatment is colored.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com