Dynamic phosphorization device and method for metal wires

A technology of metal wire and driving device, which is applied in the coating process of metal materials, phosphating, etc., can solve the problems of not meeting the requirements of later drawing speed increase, unsatisfactory phosphating effect, and large space occupation, etc., to achieve ideal phosphating effect , reduce plant construction investment, reduce the effect of plant length requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the examples.

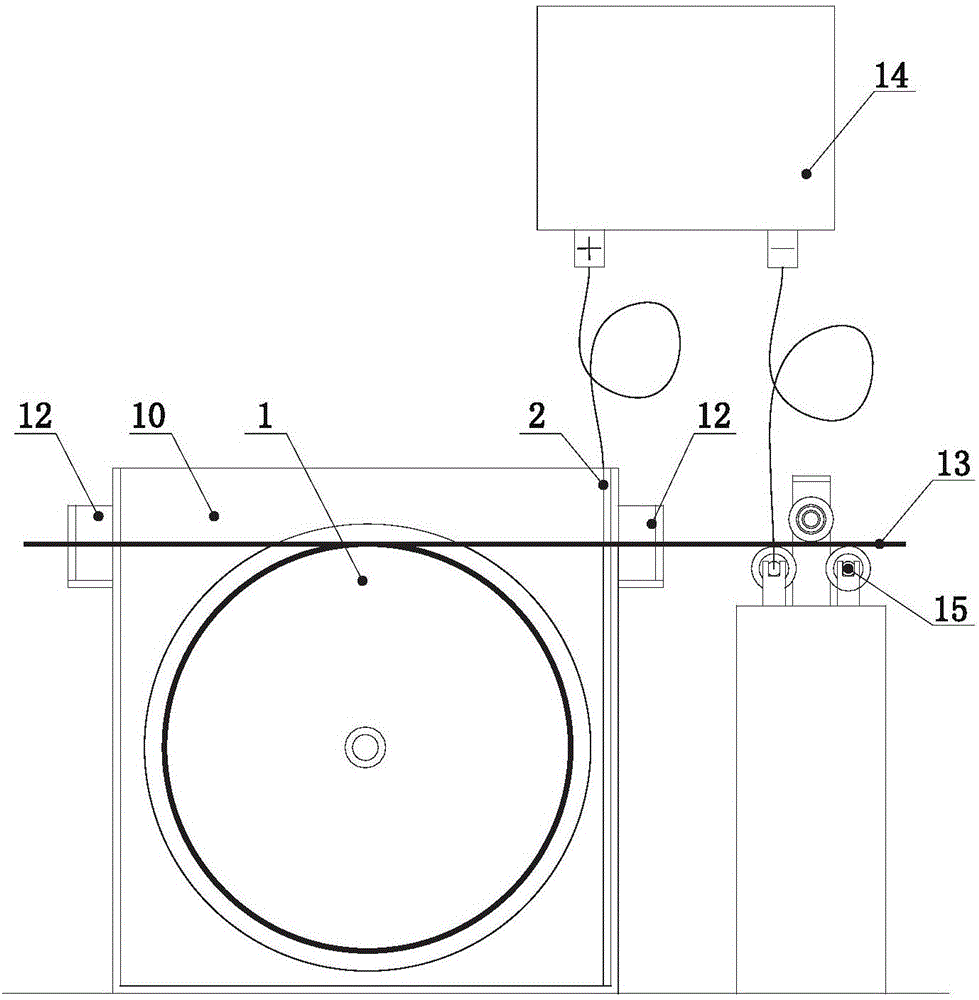

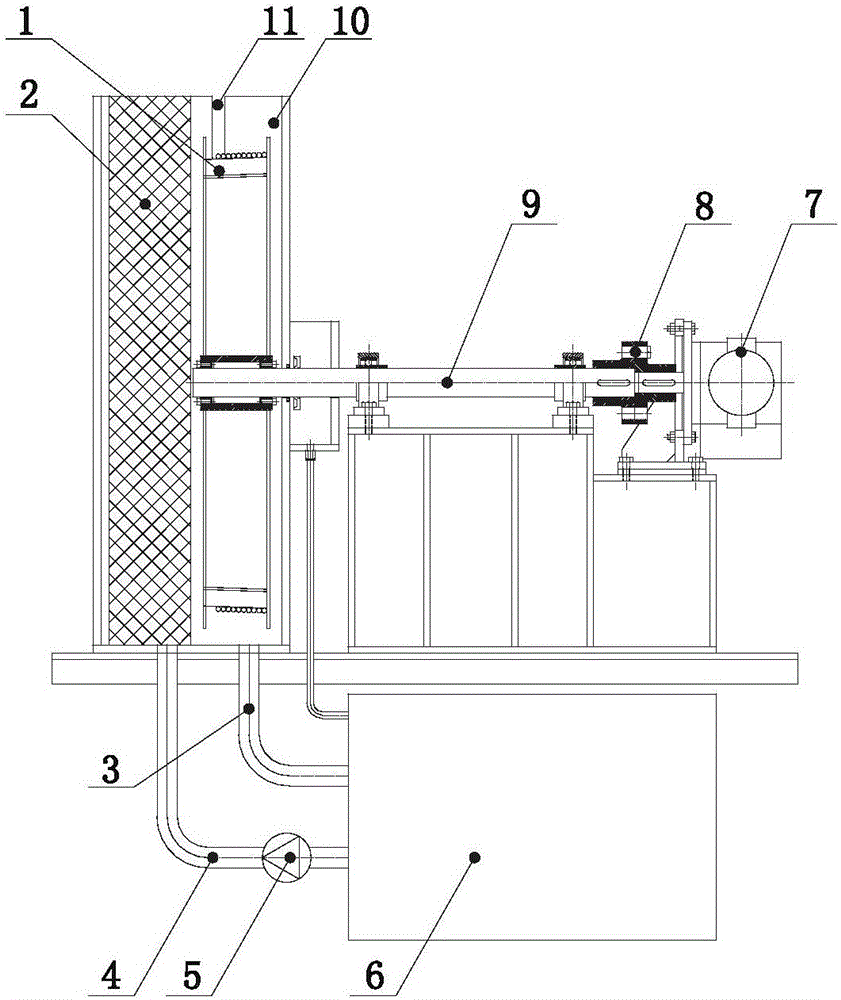

[0029] Such as figure 1 and figure 2 As shown, the present invention is provided with a phosphating tank 10 , a conductive device 15 , a coiling device and a low-voltage high-power power supply 14 , and the conductive device 15 is close to the wire inlet position of the phosphating tank 10 . The inner surface of the phosphating tank 10 is provided with a metal electrode plate 2, the metal electrode plate 2 is connected to the positive pole of the low-voltage high-power power supply 14 through a cable, and the conductive device 15 is connected to the negative pole of the low-voltage high-power power supply 14 through a cable. The conductive device 15 is provided with a conductive voltage roller, and the conductive voltage roller is used to compress the wire 13 .

[0030] The coiling device includes a reel 1 and a coiling drive device 7. The reel 1 is set inside the phosphating ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com