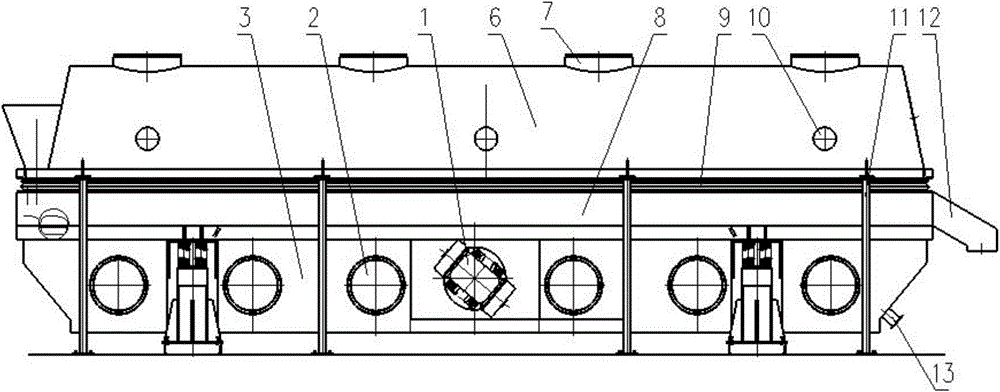

White granulated sugar vibrated fluidized bed

A vibrating fluidized bed and white sugar technology, which is applied in sugar drying, sucrose production, sugar production, etc., can solve the problems of white sugar leakage and loss, and achieve the effects of reducing pollution, long life and complete appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

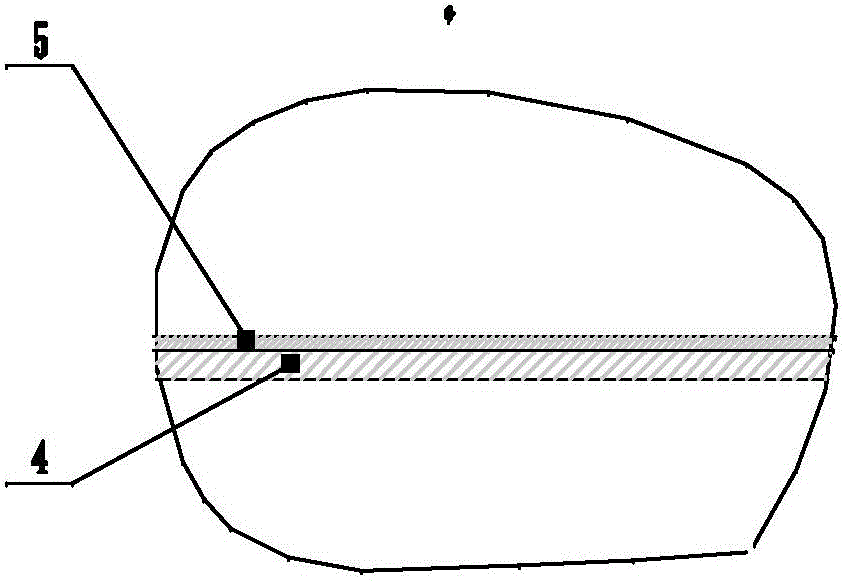

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] In the manufacturing process of white granulated sugar, the technical indicators of white granulated sugar drying and cooling are as follows:

[0034] 1. Moisture content of granulated sugar ≤1.5% before drying

[0035] 2. Moisture content of granulated sugar after drying ≤0.05%

[0036] 3. System steam pressure ≥ 0.4Mpa

[0037] 4. Suitable for sugar particle size range: 0.3~1.5mm

[0038] 5. Sugar temperature after cooling: ≤10°C ambient temperature (natural air cooling)

[0039] 6. Recovery rate of powdered sugar: recovery by first-level cyclone dust removal, recovery efficiency ≥ 99%

[0040] For this reason, it is necessary to fluidize the high-temperature and high-humidity sugar. Application of vibrating fluidized bed fluidization technology in sugar drying and cooling process:

[0041] At present, domestic sugar factories m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com