Hydroxyethylenediphosphonic acid production equipment and method

A hydroxyethylene diphosphonic acid, a technology for producing hydroxyethylene diphosphonic acid, applied in separation methods, chemical instruments and methods, organic chemistry, etc., can solve the volatilization loss of acetyl chloride, prolong the reaction time, and the reaction is not stable and other problems, to achieve the effect of speeding up the reaction, improving the quality of by-product hydrochloric acid, and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

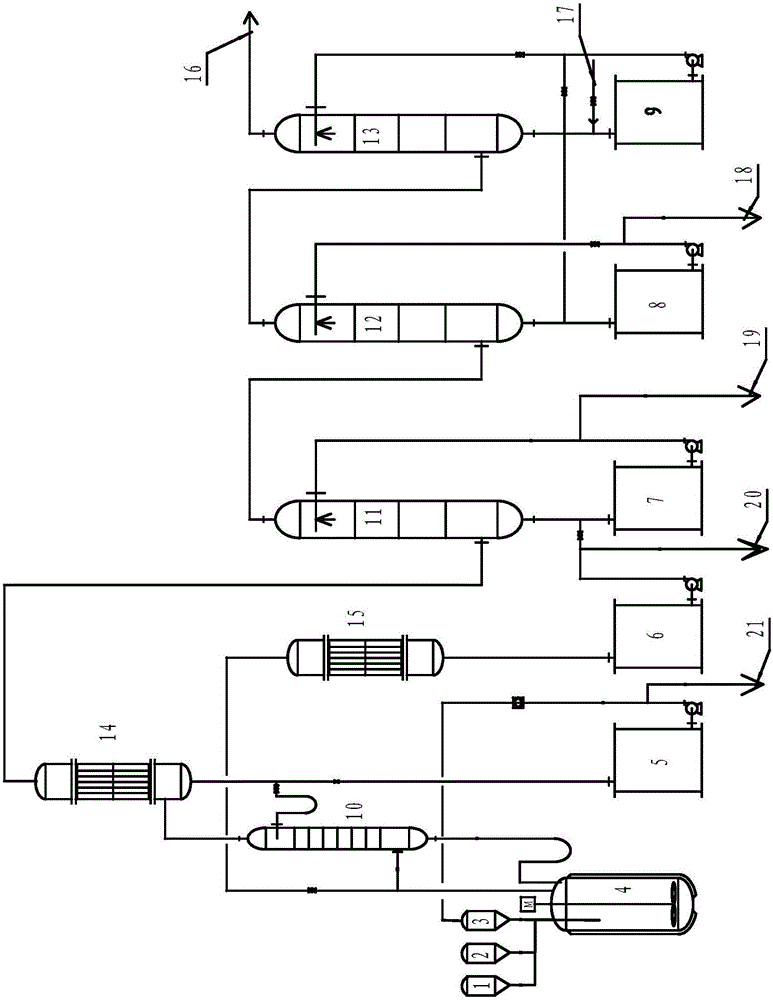

[0028] Hydroxyethylene diphosphonic acid production equipment is characterized by: a phosphorus trichloride feed tank 1 connected in parallel, a mixed acid feed tank 2 of hydrochloric acid and acetic acid, a glacial acetic acid or acetyl chloride feed tank 3 is connected with the feed port of the reactor 4 The outlet at the top of the reactor 4 is connected to the fractionation tower 10 one way, and the other way is connected to the receiving tank 6 of acetic acid in the hydrolysis stage through the acetic acid condenser 15. The upper outlet of the fractionating tower 10 is connected to the receiving tank 5 of acetyl chloride, and the top gas outlet is The acid chloride condenser 14 is connected, the acetyl chloride condensed in the condenser is led to the receiving tank 5 of acetyl chloride, the uncondensed gas enters the lower inlet of the hydrogen chloride gas scrubber 11, and the bottom of the hydrogen chloride gas scrubber 11 is connected to the acetic acid-hydrochloric acid...

Embodiment 2

[0040] Add 40Kg of industrial glacial acetic acid, 100Kg of recovered washing liquid containing 35.7% of acetic acid and 21.4% of hydrogen chloride into the reactor 4, start stirring, and slowly add 165Kg of phosphorus trichloride. Other operations are the same as in Example 1. In the reaction, 32Kg of acetyl chloride is recovered, and after hydrolysis, a 50% product of 230Kg, 85% acetic acid 27.6Kg, and a dilute acetic acid-hydrochloric acid mixture: 77Kg, 30% hydrochloric acid 391Kg.

Embodiment 3

[0042] Add 48Kg of recovered 91% acetic acid, 91Kg of recovered washing liquid containing 35.7% of acetic acid and 21.4% of hydrogen chloride into the reactor 4, start stirring, and slowly add 165Kg of phosphorus trichloride. Other operations were the same as in Example 1. 31 Kg of acetyl chloride was collected and hydrolyzed with water to obtain 228 Kg of 50% HEDP product, 28 Kg of 85% acetic acid solution, and 82 Kg of acetic acid-hydrochloric acid mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com