Method for wet commercialization of dye

A dye and wet process technology, applied in the field of dye preparation, can solve the problems of long repeated operations, decreased dye quality, large measurement error, etc., and achieves the effects of improving labor and equipment efficiency, reducing hydrolysis side reactions, and reducing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

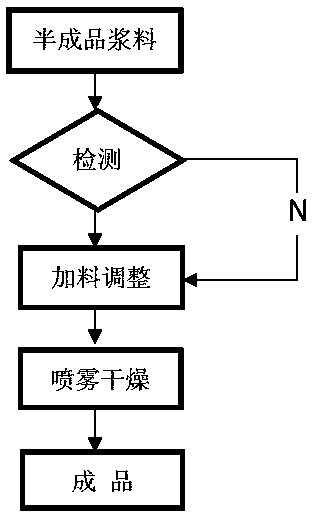

[0034] A kind of active red wet method commercialization method, process flow chart sees figure 1 ,Specific steps are as follows:

[0035] 1. Mix two batches of dyes evenly in a 100 cubic meter reactor to obtain a semi-finished slurry. Take 100 g of the slurry sample and mark it as A 1 ;

[0036] 2. Add 200 kg Yuanming powder to the above-mentioned semi-finished product slurry, and stir for 1 hour to obtain a slurry dye sample, sample 100 g, and mark it as A 2 .

[0037] 1) From A 1 and A 2 Take 5g (accurate to 0.001g) from each of them and put them in an oven at 105°C to dry to constant weight, that is, measure the solid content (%)G 1 =25.6%, G 2 =26.2%;

[0038] 2) According to the solid content G 1 , G 2 Calculate the slurry amount M containing 1g solid dyestuff before and after adding Yuanmingfen 1 , M 2 , the amount of slurry containing 1g of solid dye (g) = 1 / solid content (%) (accurate to 0.001g), according to the calculation results to get M 1 =3.906, M 2...

Embodiment 2

[0071] A kind of wet blending of active navy blue, concrete steps are as follows:

[0072] 1. Mix two batches of dyes evenly in a 200 cubic meter reactor to obtain a semi-finished slurry. Take 100 g of the slurry sample and mark it as A 1 ;

[0073] 2. Add 700 kg of Yuanming powder to the above-mentioned semi-finished product slurry, and after stirring for 1 hour, obtain a slurry dye sample, take 100 g of the sample, and mark it as A 2 .

[0074] 1) From A 1 and A 2 Take 5g (accurate to 0.001g) from each of them and put them in an oven at 105°C to dry to constant weight, that is, measure the solid content (%)G 1 =29.5%, G 2 =31.0%;

[0075] 2) According to the solid content G 1 , G 2 Calculate the slurry amount M containing 1g solid dyestuff before and after adding Yuanmingfen 1 , M 2 , the amount of slurry containing 1g of solid dye (g) = 1 / solid content (%) (accurate to 0.001g), according to the calculation results to get M 1 =3.390, M 2 =3.226, take A with weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com